RFID-Fitted Half Pallet Set For LogiMAT Debut

5th December 2016

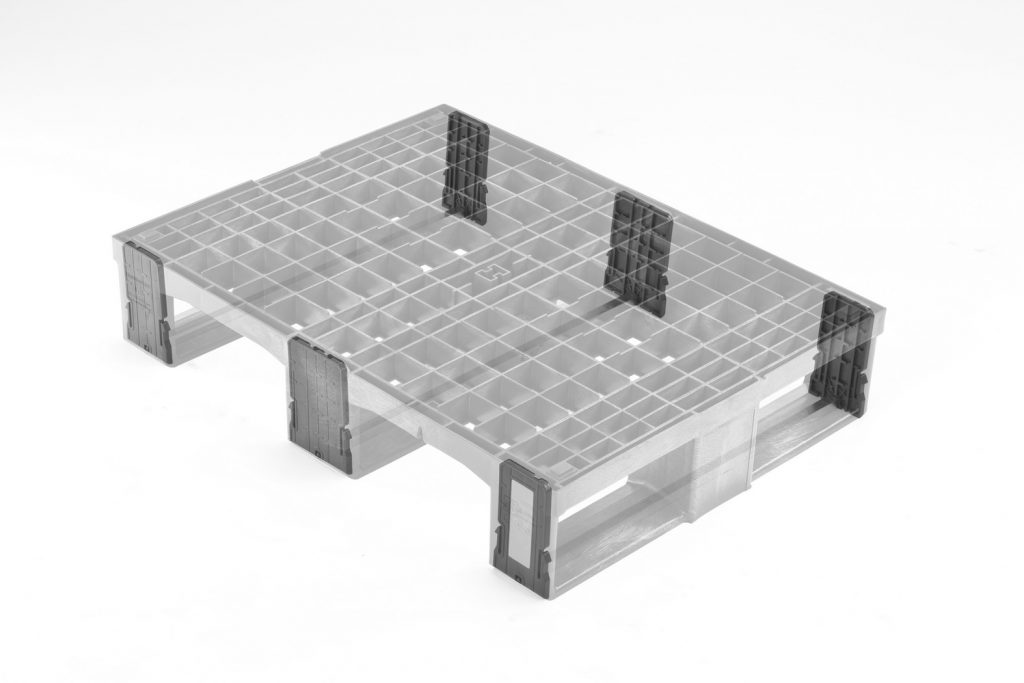

Cabka-IPS, specialist for product solutions made from recycled plastics, will be presenting the new Heilbronner half pallet (HHP) for the first time at the International Trade Fair for Distribution, Materials Handling, and Information Flow LogiMAT (March 14-16 2017). The Heilbronner is a cost-efficient and environmentally friendly alternative to the wooden Düsseldorf pallet. It was developed to be the future standard for production facilities with a high degree of automation. This innovative loading equipment has superior ergonomic handling and a long service life. Thanks to the latest RFID technology, warehouse staff and suppliers can easily track their shipments and in this way optimize their entire supply chain management. The plastic pallet is the result of close cooperation between Cabka-IPS and the pooling company GreenCycle, which is part of the Schwarz Group (Lidl and Kaufland).

Cabka-IPS’s Heilbronner half pallet is designed to be especially ergonomical and is also very light with a net weight of 6.5kg. The static load is 2,000kg and the dynamic load 1,000kg. The pallet is made from robust plastic (HDPE) and is 100 percent recyclable. It is easy to clean and therefore a favourite in the food industry. In addition, as compared to wooden pallets, plastic reduces the risk of injury. Sharp edges and splinters, which can damage goods and conveyor systems, are now a thing of the past. Users can significantly reduce process downtimes and effectively lower costs. Even with increasing circulation times, the pallet maintains its quality and stands out on account of its long service life.

More than 1.5 million pallets are already being used in the GreenCycle GmbH pool.

The Heilbronner half pallet is particularly suitable for automatic roller and chain conveyors as it has three aluminum rails that can each be replaced as needed. The rails are also very resistant to wear. In the area by the skids, the deck has been lowered by 4mm so that the pallets can be stacked in a safe and stable manner. This creates edges so that even stacked pallets stay securely in place and don’t slip. The pallets can also be used to lock stacks of boxes. In addition, the Heilbronner half pallet has hooks for stretch film on two sides. These ensure that the film can be secured safely and simply. The hooks prevent the film from getting caught on the pallet feet, and the film can therefore also be removed much faster.

The pallets are equipped with two RFID transponders in the pallet feet so that users can trace the transport distances of their goods. This makes each pallet uniquely identifiable. The RFID technology provides a real-time overview of goods movements and reliably pinpoints their location. The data is presented clearly and can be accessed in real time. Users can closely monitor loading equipment inventories and minimize pallet loss. The Heilbronner half pallet therefore serves both as traditional loading equipment and an information carrier that ensures smooth supply chain management, complete documentation of all activities in the supply chain, and reduced circulation costs.

Cabka-IPS at LogiMAT: Hall 3 / Booth 3B31