“Seatbelts For Pallets” Testing Lab Aims To Boost Standards

5th October 2016

In a continuing effort to advance sustainable packaging solutions and ensure their industry leading quality standards, Midwest Precision Products, Inc. (MPP: North Royalton, OH) has recently opened their state-of-theart Testing Laboratory.

A world leader in providing retractable, reusable, self-contained cargo restraints for material handling applications since 1992, MPP formed its Testing Lab, including its testing fixtures and machines, primarily for two reasons:

Performance Standards: To test products to insure that they meet the minimum standards set forth by

the Automotive industry and other customers; when used in harsh industrial environments before the products are made available for sale to customers.

Experimental Testing: On-going product improvements and innovations are rigorously tested by these devices to ensure maximum performance and quality goals are met before permanent implementation into the market; perhaps beyond customer standards.

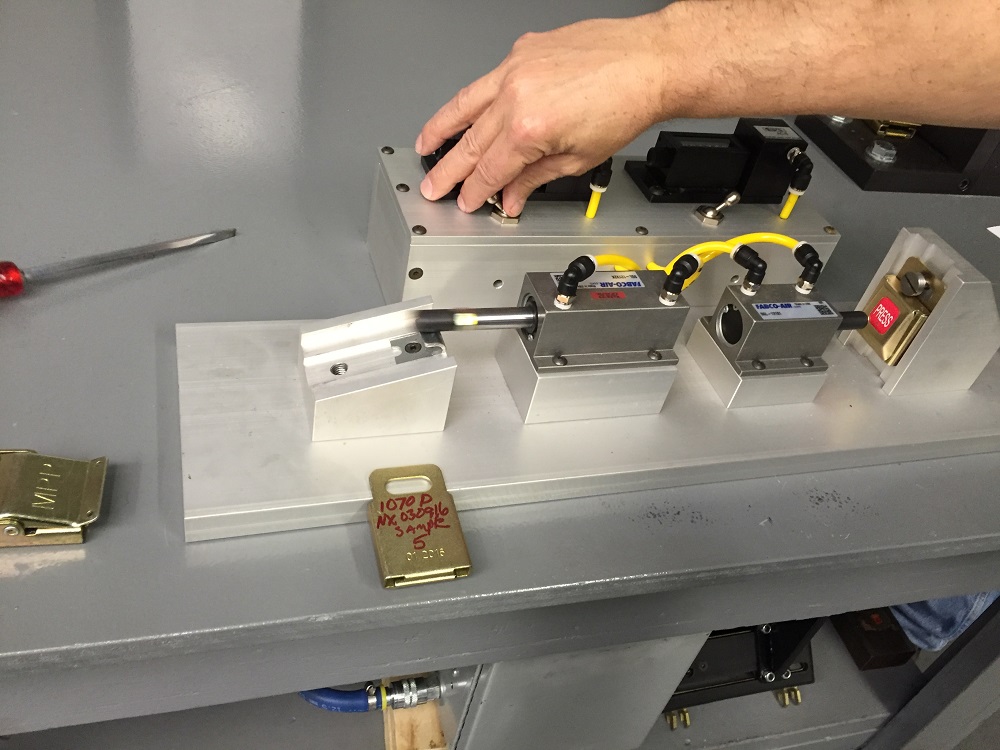

MPP manufactures its Seatbelts for Pallets products overseas as a cost saving measure. The retractable belts simply attach and reattach per repeatable loading/unloading operations. Upon receipt of deliveries, the products are inspected in a non-destructive fashion via a random sampling that are tested for “fit-form-function”. MPPs facility features custom made laboratory devices that are engineered for testing of retractors & buckles including:

- Tensile testing of both retractor & buckle assemblies to ultimate

strength/failure - Shock testing of mated retractor-buckles

- Load Drop force testing of mated retractor-buckles

- Engagement force of retractor tongues into buckles

- Dis-engagement forces measured of retractor tongue from buckle

- Duty cycle testing of retractors and buckles

- Retractor webbing extension, working length, locking and un-

locking to requisite standards