The Cotton On Group, one of Australia’s largest global retailers, has once again selected Vanderlande’s flexible TRAYSORTER solution in order to optimise the processes within its distribution centre (DC) in Avalon Victoria.

The Group’s DC serves both Australian retail stores and online customers. The Cotton On Group acquired its first Vanderlande TRAYSORTER in 2018, and following the success of this project, has now begun live operations with its second TRAYSORTER in the same facility.

The Cotton On Group has eight brands, operates over 1,400 stores in 20 countries, and employs 20,000 team members across the world. In 2018, it issued a tender for a project that would help to enhance the overall performance at its Avalon Distribution Centre. In response, Vanderlande designed a system that was capable of handling any combination of order type and delivery requirements, as well as adapting seamlessly to the Cotton On Group’s strategic objectives.

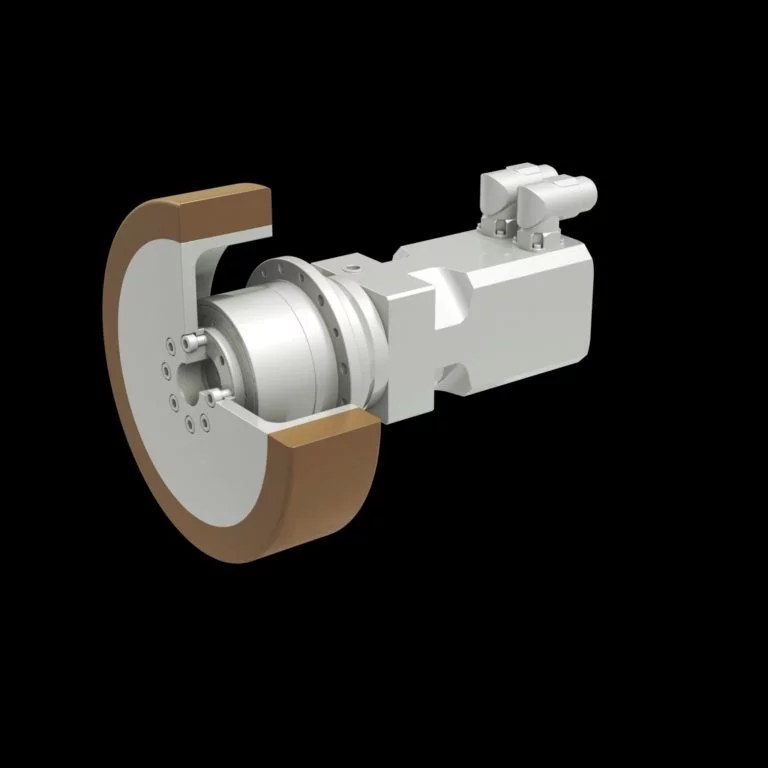

The system makes use of a TRAYSORTER – a highly flexible flat sorter, also known as a ‘Bombay sorter’. It is suitable for handling a wide range of products, from apparel, accessories and small parcels, to shoe boxes and multimedia items.

The TRAYSORTER’s adaptability (supported by its interchangeable tray types) allows the Cotton On Group to meet its various sorting needs. In addition, its modular design means that it is fully scalable and can be adapted to individual requirements. The solution can also adjust easily to fit into an existing warehouse architecture.

General Manager, Cotton On Group Distribution, Andy Sanderson, explains that the first TRAYSORTER significantly improved efficiency and productivity in the distribution centre: “With the Vanderlande solution, we have been able to dramatically reduce the time between picking items through to delivery, as well as improve picking accuracy. The TRAYSORTER also supports a more efficient picking strategy, will help us to achieve sustainable growth, and most importantly, will allow us to continually deliver an excellent service to our customers.

“Given the success of the first project and the positive impact it has had on our DC, the next logical step for us was simple – to add another one! The second TRAYSORTER became operational three weeks ahead of the agreed schedule and we handled the 2020 peaks with ease. We now look on Vanderlande as being a reliable partner to The Cotton On Group.”

Vanderlande’s MD Warehousing Solutions ANZ, Roald de Groot, adds: “Vanderlande has a focus on solutions for specific industries, such as fashion. As a result, we have an in-depth understanding of the complexities involved in running a successful fashion warehousing business. Our scalable solution was the perfect match for the Cotton On Group’s omni-channel distribution approach. Vanderlande is proud to support one of Australia’s retail icons in further optimising its warehouse processes.”