Industry View: Automated Tugger Trains Boost Ergonomics, Efficiency and Value

4th September 2020

STILL experts explain the benefits of the tugger train system:

Across all industries, companies are faced with the growing challenge of using resources in an optimised, profitable and sustainable way in order to survive in dynamic market environments. A question that often arises, especially in logistics contexts, is “Man or machine?” Forklift-free production logistics using automated tugger train systems is a clear example of how the one does not exclude the other. On the contrary, synergies between the two components ensure high efficiency while creating value and promoting the employees’ health. With more than 100 years of experience in designing and implementing intelligent intralogistics solutions, STILL is a competent, innovative partner when it comes to optimising production logistics and using automated processes to successfully shape the future.

Among experts in Europe and Germany, the concept of the tugger train system has stood for lean processes and synchronised intralogistics since the turn of the millennium. The way it works goes back to the milk run principle already used to supply foodstuffs in the USA in the 1960s. Just like the milkman doing his round every morning, exchanging empty containers for full ones, production plants are supplied with materials in a timely, needs-based way by tugger trucks. The supply of materials or onward transport of sub-products takes place in the same train.

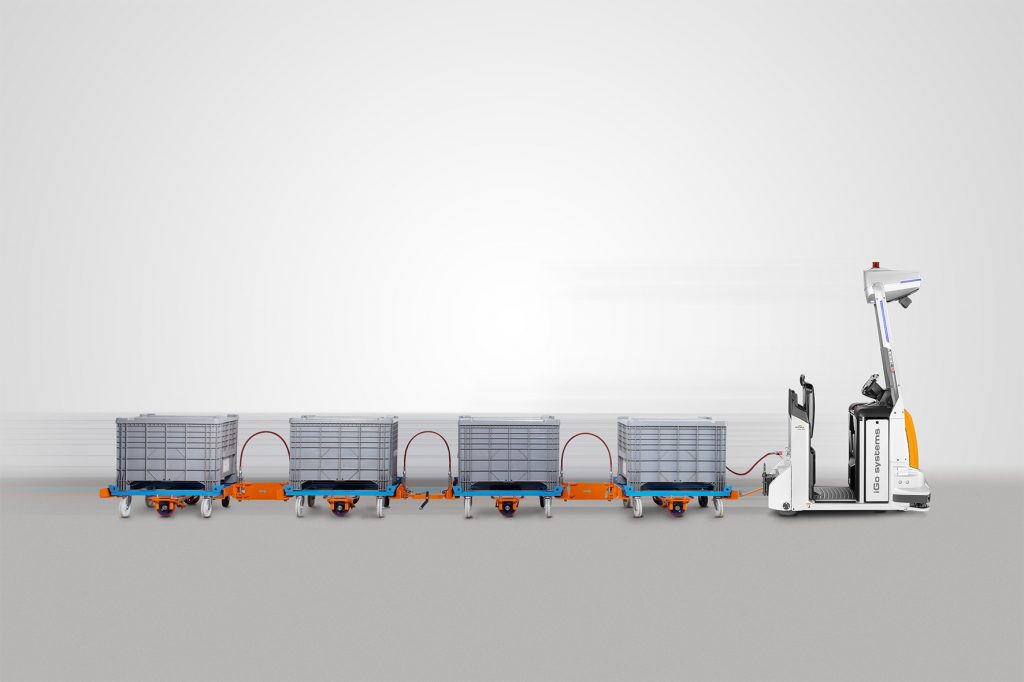

The tugger train system is a systematic further development of this idea. The use of trolleys which are pushed into frames towed by a tugger truck allows for a fast and flexible supply of entire production lines, just-in-time or just-in-sequence. Perfect interaction between trolley and frame is an essential key to success in this respect. In addition to the efficient, reliable supply and removal of process materials, companies also profit in terms of increased productivity, cost optimisation and production individuality. Also, a cyclically synchronised supply via an unchanging route also ensures safety, smooth in-house traffic and ergonomic working conditions.

Train by train: From storage sheds in the port of Hamburg to the automotive innovation sector

More than a decade of experience in developing and implementing innovative tugger train systems, and more than seventy years of competence in the development of powerful electric trucks make STILL a competent system supplier of tugger trains. In 2008, STILL once again lived up to its reputation as a pioneer of the intralogistics sector: together with the automotive manufacturer BMW, the Hamburg company developed the STILL LiftRunner tugger train, thereby paving the way in Germany for forklift-free production line supply based on innovative lean principles. The STILL LiftRunner has been the benchmark for tugger train systems right up to the present day, and the basis of all further developments in the past 10 years.

Just how early STILL recognised and implemented the concept of tugger trucks and forklift-free logistics processes is shown by the development of the EK 2000 electric cart as early as 1946 and the introduction of the Muli-Mobil three-wheel tractor only a few years later. The Muli-Mobil was already pulling up to ten trailers through the port of Hamburg during the years of the German economic boom after the Second World War. This makes the STILL LiftRunner with its innovative frames and trolleys and the patented transport and removal system the conceptual and technological advancement of one of the first successful products in what is today’s 100-year company history of STILL.

Towing automatically: Tugger train systems as driving forces of automation

The digital revolution – especially in online retailing – is leading to a dynamisation of production and supply chains across all sectors. Driverless transport systems are an efficient option to meet the needs of flexibility, individualisation and process safety: in particular, partly or fully-automated tugger trains, supported by state-of-the-art navigation and control technologies, are taking over the task of supplying production plants and load handling. The benefits are obvious. Flexible, perfectly synchronised production supply, optimised materials stocks, minimised errors and accidents, and the needs-based deployment of personnel are only a few of the advantages.

Many STILL customers have been using these opportunities for a long time – and together with STILL’s intralogistics consultants they have changed their production supply methods to tugger train systems. 100 years of intralogistics experience coupled with soundly based technological know-how and in-house intralogistics consultancy make STILL the perfect partner for logistics automation processes. This is also confirmed by external experts: in 2019, the company received the coveted IFOY award in the “AGV & Intralogistics Robot” category for the STILL LiftRunner with automated loading and unloading and for the LTX 50 electric truck.

Man and machine in ergonomic interaction

Qualified, healthy and motivated skilled personnel are one of the most important resources of successful companies even in the age of automation. The example of the automated tugger train system clearly shows that automation is not the same as economising on jobs. Of course automation is an entrepreneurial instrument to counteract challenges such as the shortage of specialist staff, rising wage costs and a high pressure to achieve flexibility, but it is much more than that. It also means making the best possible use of technological and human resources and exploiting synergies. When intelligent machines in production ensure safety and reliable processes and also take on physically heavy, repetitive work, productivity and efficiency increase. At the same time, employees benefit from improved working conditions and health protection as well as more freedom for creative and responsible tasks thanks to automation. For example, a single employee is able to undertake the logistical responsibility for an entire production line instead of merely for a single production step.