Konecranes lift trucks upgraded

13th July 2021

Since 2019, Konecranes has regularly introduced a range of enhancements for safety and productivity in its Lifetime Advantage programme. Now, as part of this long-term commitment to improving the performance of existing lift trucks, Konecranes is introducing four more innovative ways to raise safety and productivity for its customers around the world.

All four upgrades are specific solutions that can be fitted to Konecranes lift trucks on customer sites. They are not service packages but are intended to improve equipment performance with the latest available technology.

“Safety and productivity are among the two most important priorities for our customers,” says Johan Kårhammer, Global Spare Parts Operations Manager at Konecranes Lift Trucks. “So, in this latest release, they can choose any or all of two safety and two productivity packages that can be installed on one truck, all trucks at one site, or even across a global fleet.”

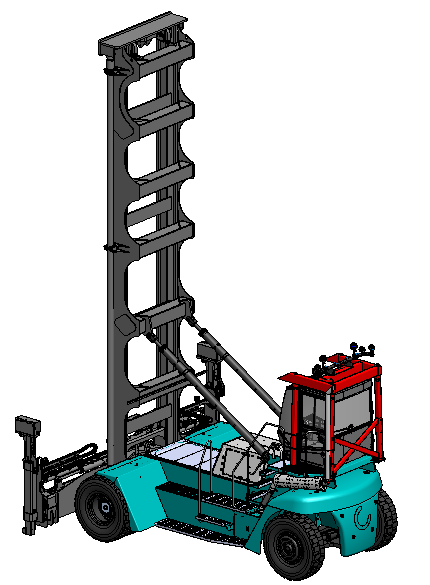

Of the two new safety improvements, Over Head Guard (pictured) is a retrofit for empty container handlers that will protect the operator from a falling object using a safety cage mounted around the cabin. Thankfully, falling objects are quite rare in container yards, but empty containers can sometimes drop accidentally due to the height of the mast. The retrofit is available only for Generation B and C empty container handlers.

Customers can also upgrade their lift truck safety by enhancing peripheral and forward visibility with a Roof LED Bar. This is a preassembled light fitting mounted on the truck’s roof to make operations brighter when the surrounding area is not fully illuminated, such as at night, in shadow, or indoors. Available at different illumination levels, it can be easily fitted to any type of forklift or container handler, and controlled from the operator’s dashboard inside the cabin. Better lighting also reduces driver fatigue, as they are not distracted by the need to avoid hard-to-see obstacles and can fully focus on delivering the load safely.

Productivity gets a boost with Hydraulic Pump Upgrade 2x105cc. On Konecranes Liftace reach stackers and TCE5 models with a suitable configuration, replacing the existing 75cc pump with a 105cc pump increases the operational speed of lifting, extending, retracting and manoeuvring actions. Faster movements mean faster work cycles and the result is more container stacking during each shift. Easy to install, the difference in work flow can be seen immediately.

The second productivity improvement is a static weighing system retrofit for Generation B and C reach stackers. Operators can weigh containers by lifting them for a few seconds, then touching a button to send the measured weight to a central database, such as the Terminal Operating System (TOS) or the yourKONECRANES customer portal, where it is linked to the container ID. This provides the information for an automated Verified Gross Mass (VGM) declaration with +/- 1% full scale accuracy and eliminates the need for a separate weighing procedure when loading containers for transport. Reducing the time and processes required for each container to pass through the container yard, this retrofit saves on operational costs and increases overall site productivity.

As in the past, the Konecranes global distributor network will again play a significant role in bringing the new Lifetime Advantage options to Konecranes customers around the world.

“With the popularity of our previous upgrades and retrofits, I’m pleased to see this new range available so soon,” says Patrik Lundbäck, Director and Head of Sales and Distribution at Konecranes Lift Trucks. “The Konecranes Lifetime Advantage is based on the needs of our customers in their daily activities. It’s meant to refine their operations and add a sharper edge to their container handling.”