Leadership Transition for Lift Tables Supplier

4th April 2023

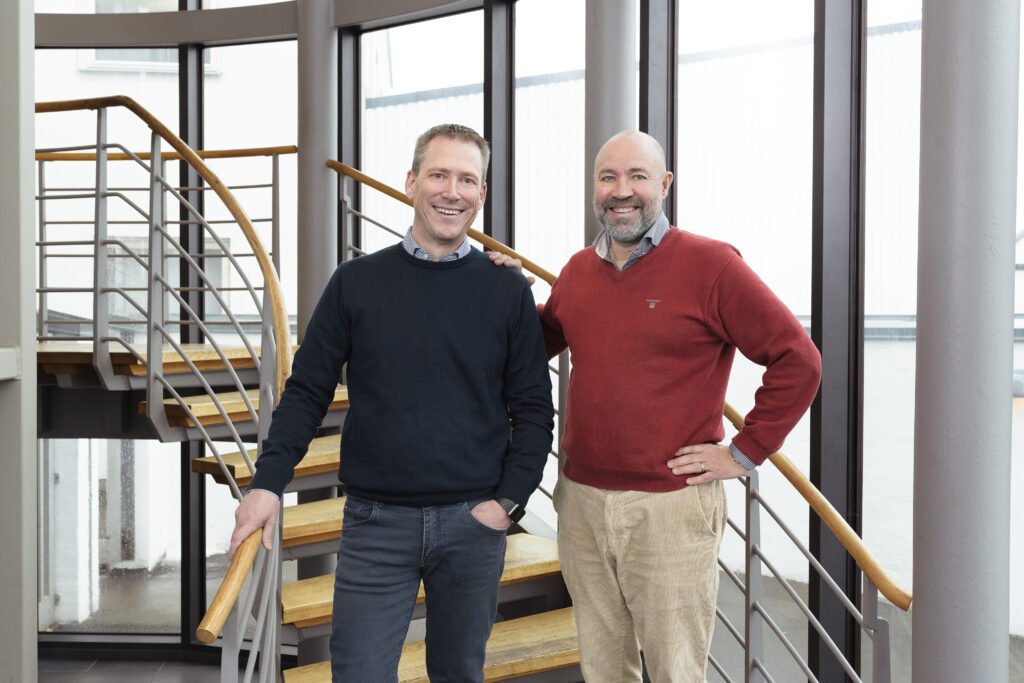

Hymo VPG, lift tables manufacturer based in Sweden, is excited to announce a leadership transition within its EMEA team. Håkan Nilsson (pictured, right) has stepped down as the leader at the end of March and Pär Martinsson (left) assumed the role of leader and general manager, effective April 1st.

The company statement read, “during his tenure, Håkan made significant contributions to our company and was an instrumental leader for our EMEA team. We want to express our gratitude for his outstanding leadership and dedication, which were pivotal to our success. We wish him all the best in his future endeavours. We are delighted to welcome Pär Martinsson as our new leader. A long-time member of our team, Pär has a deep understanding of our business, people, and systems. His clear vision and enthusiasm make us confident that he will lead our EMEA team to even greater heights and achieve significant milestones.”

Lift tables going global

Martinsson says, “I am very excited to lead the EMEA team in these times. With a market that is becoming increasingly global, and valuing safety and efficiency more than ever, we are ideally positioned to increase value for our customers.”

Martinsson’s experience and accomplishments, such as enhancing supply chains as the Purchasing Manager and transforming and digitizing operations, demonstrate his ability to tackle challenges and drive change. Hymo VPG believe he is the perfect candidate to lead the EMEA team into the future.

New Levitator Ergonomic Working Platform Helps System Integrators Increase Sales and Create World-Class Pick and Pack Stations

Hymo VPG’s new Levitator height adjustable platform offers a range of benefits for system integrators working with design and layout of advanced distribution and logistics centres. The platform allows for completely new ways of designing world-class pick and pack stations, whilst also providing opportunities for cost and energy savings.

One of the key advantages of the Levitator is its design flexibility, as well as its unique oil-free design. “The project started initially with one of the global providers of warehouse automation who were designing a fully automated solution for a distribution centre, however, since the DC was to handle fresh food and other sensitive products, they needed an all oil-free solution in the pick and pack area. That is how the Levitator originated and the rest is history,” says Daniel Andersson, Strategic Key Account Manager at VPG, and the leader for the new Levitator.

The Levitator allows for new designs that were not previously possible. Its oil-free design means it can be placed in areas where oil is prohibited, but it also offers more flexibility than traditional scissor lifts. “Scissor lifts are great for working platforms, but their geometric construction is fixed and inflexible. Here the Levitator enables unique values, only the imagination sets the limits,” says Daniel. The Levitator’s innovative platform structure enables new designs, U- or V-shape, or with a minimal width. This means that every pick and pack station can be equipped with the ideal and perfectly fitting ergonomic Levitator.

The Levitator also offers significant cost savings. “A very important matter that is often overseen is the total costs to run a working platform over time. The Levitator enables significant economic values. Firstly, it has a low energy consumption. With today’s rising energy costs every kW saved, is money saved, and over the lifetime of a working platform we are talking a substantial amount of money,” says Daniel. Its electric drive allows for lower energy consumption, and also minimizes costs for service and maintenance, a quicker and easier installation. This, combined with its oil-free design, means that the number of service and repair occasions and requirement for spare parts is much lower. Additionally, the Levitator is a convenient plug and play solution that can be easily installed, eliminating the need for a certified hydraulic engineer therefore saving more valuable time, and in effect money.

In summary, the new Levitator offers increased possibilities for creating innovative warehouse automation solutions, whilst being cost effective. Overall, the New Levitator will provide long term cost savings alongside environmental benefits. It can be designed freely to fit in any space, and its oil-free, electric drive allows for lower energy consumption and minimal maintenance costs. This makes it an ideal solution for anyone looking to grow their sales and create world-class pick and pack stations.