Plastic Modular Belt Increases Multi-directional Movement

3rd October 2024

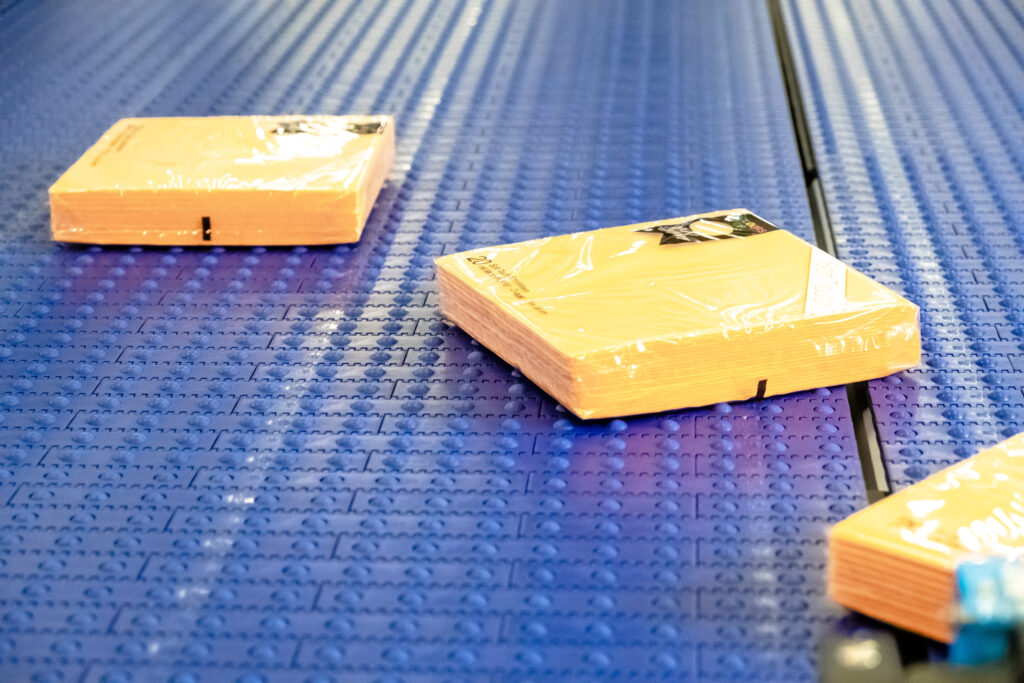

Conveyor specialist Habasit launched the HabasitLINK M2483 Sphere Top 1” plastic modular belt to offer the courier express and parcel (CEP) market new possibilities in multi-directional movement of goods on conveyors. It allows facilities to move goods across conveyor belts in all directions, including differently to a belt’s conveying path, in a controlled manner.

The launch came at a time when volumes in logistics, parcel- and unit-handling facilities continued to grow and provide facilities with a new conveying solution that offers greater automation and reduces labour requirements.

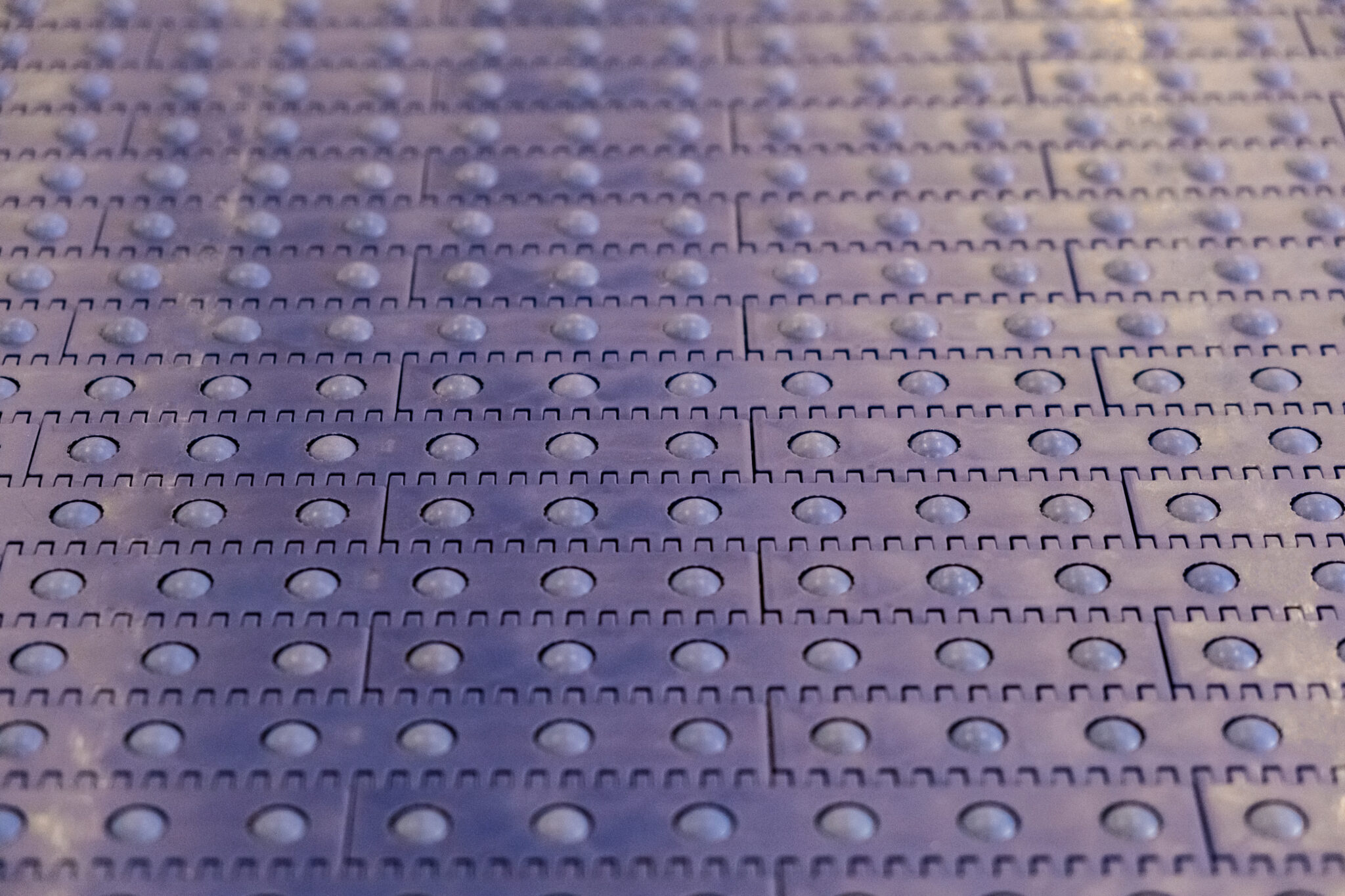

The HabasitLINK M2483 Sphere Top 1” plastic modular belt is a compelling solution for the controlled, multi-directional movement of goods on conveyor belts, even if different from the belt’s conveying direction. It also facilitates the rotary movement of goods, further increasing directional movement possibilities. The belt is particularly suitable for logistics and parcel handling applications where goods are accelerated, sorted, diverted, merged, turned, accumulated, or re-spaced – whether small or large, packed or unpacked.

Controlled multi-directional movement of goods

“The new sphere top belt provides facility managers with increased flexibility at a time where the CEP industry is under increased pressure to process more parcels than ever,” explained Anders Nilsson, portfolio manager at Habasit. “By using different combinations of fabric belts, speeds, and directions, the load can be held in place, moved forwards, backwards, sideways, or diagonally, or even rotated as needed.

“Furthermore, the rotating sphere balls can target almost any angle allowed by the conveying system, making it easier to handle packed goods during automated add-on applications like printing, scanning, or rejection after inspection,” concluded Nilsson.

HabasitLINK M2483 Sphere Top 1” plastic modular belt’s design has been optimized to have a long service lifetime, reducing total cost of ownership. For example, it has steel rod floaters that stop dust and grease build up around the spheres, so their pivoting action is unhindered and their functionality is secured. Habasit offers R&D engineering support to its customers, including in-system designs, and provides detailed engineering guidelines with solutions for common applications. www.habasit.com

similar news