RFID Case Study: Can a Supply Chain be Digitised?

27th May 2020

Can a supply chain be digitised? Experts from German RFID specialist Kathrein Solutions say yes:

The global market is setting new standards for a more intelligent supply chain. A Stuttgart-based automotive manufacturer wanted to lead the way regarding digitisation and introduced RFID[1] as the basic infrastructure technology in its manufacturing plant. The aim was to define the factory of the future and to implement its products in the digitised factory. In order to realise this vision, it was also important to integrate the suppliers from the very beginning. The use of RFID technology in the competition for future orders was a decisive criterion for automotive suppliers. Reliability was to be created through a more intelligent supply chain with new tools and valid real-time insights. The supply chain consequently improves the way of collaborating and achieves an unprecedented level of transparency.

Initial situation: Supply chain management before

Logistical challenges were normally solved using barcode-based systems. However, the aim was to make companies in the automotive field also replace the old barcode structure with specially modified RFID tags. These radio-readable information carriers were used to automate localisation and identification along the entire supply and marketing chain. The Association of the Automotive Industry (VDA) described and defined this years ago by “RFID for Tracking Parts and Components in the Automotive Industry.” Up to 65 percent of the value of goods or services in a company comes from working with suppliers. This is what the “Cross-Industry Report of Standard Benchmarks” by CAPS Research states. Functioning, intelligent supply chains are, therefore, a decisive factor for a successful digital transformation of a company. What matters is speed, a complete overview of complex processes, and, of course, a maximum focus on the customer.

Solution: RFID hardware components

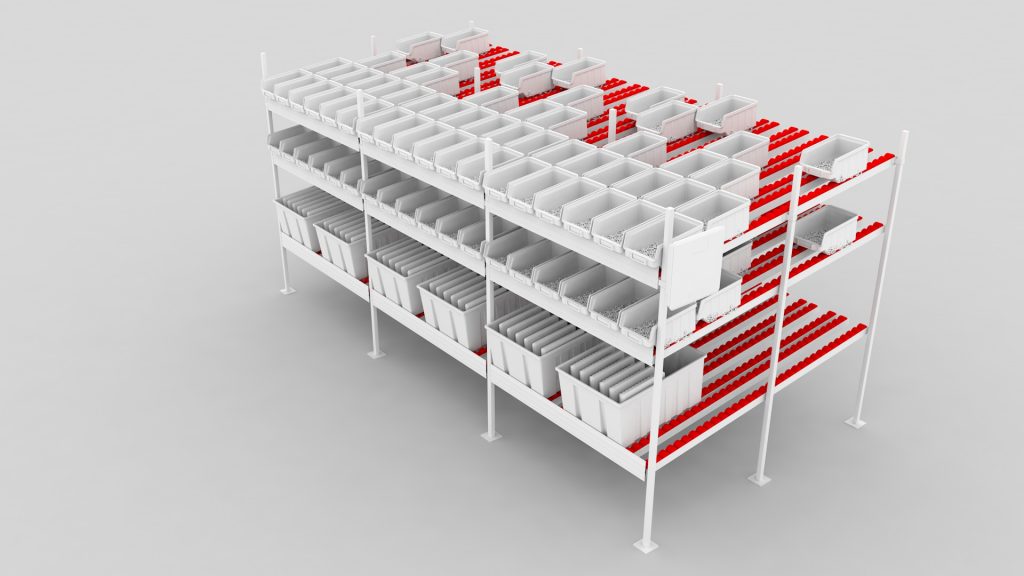

The car manufacturer relies on the use of certified RFID hardware components from Kathrein Solutions, as well as on a well-established software solution for a simple and reliable supplier connection. All relevant positions in the supply chain of the “RFID end-to-end process” were equipped with certified RFID hardware. In some cases, the hardware was specially adapted. Simple assembly and effective maintenance of the components were required and were implemented accordingly. Process security, reliability, and cost-effectiveness were the focus throughout the entire conception. All acquisition components were linked to one another using standard software to enable a simple and stable data connection. The centrepiece of the concept is the “intelligent load carrier.” All these load carriers already carry an RFID tag and a unique identification number when sent. Both processes, sorting at the crossdock as well as the transport, are carried out with RFID support. Automatic identification in the supply chain takes place wherever it is technically feasible and process-relevant. This also applies to the section incoming and outgoing goods. Storage and retrieval, loading of the route cars, and supply at the assembly line are largely automated and documented. Even the empties at the assembly line are automatically recorded on the shelves using special KanBan antennas in order to enable automatic material retrieval.

Result: A Supply Chain can be digitised!

Here, IoT digitalisation has been implemented efficiently and practically into the supply chain. Standardised RFID technology was adapted to specific requirements in a cooperative partnership with Kathrein Solutions. For example, the automated KanBan shelf was implemented successfully and cost-effectively into the system landscape. Here, an automotive manufacturer has created the perfect base for digitised manufacturing in the future and has once again proven that innovation means progress. The aforementioned aim of defining an automotive manufacturing plant of the future was achieved. Unobstructed, predictable cycles and the reduction of waiting times have been successfully and significantly improved throughout the logistics process.

[1] Radio-frequency identification