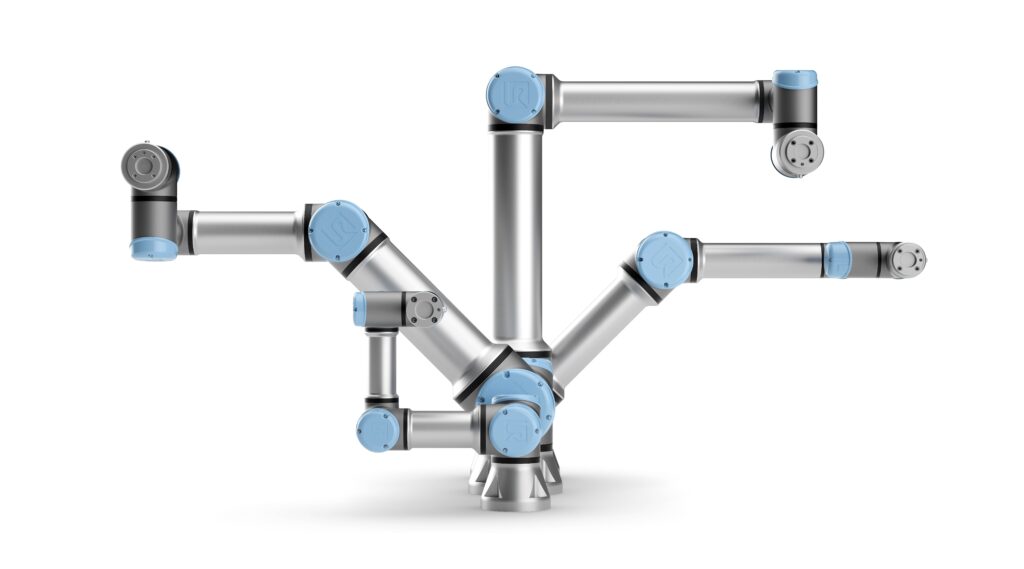

Universal Robots develops cobot interface for Siemens

8th April 2021

Universal Robots has formed a new partnership with Siemens’ TIA (Totally Integrated Automation) that will allow the integration of Universal Robots cobots into complex machine and manufacturing environments.

This new interface will facilitate a seamless integration process for machine builders and system integrators. Universal Robots’ cobots will become part of the Simatic Robot Library within Siemens’ TIA environment through an interpreter interface planned to be completed within the fourth quarter of 2021.

Mark Gray, Country Manager UK&I said, “Machinery and plant engineers as well as manufacturers with large production facilities will benefit from our cobots‘ TIA integration. Thanks to this new interface, they will soon be able to apply our cobots’ functional diversity, precision and repeatability within complex production lines, benefitting from all aspects of digitalised automation – from digital planning and integrated engineering to transparent operations.”

The holistic TIA Portal engineering framework supports users in planning extensive manufacturing automation projects. In November 2020, Siemens presented the Simatic Robot Library as an addition to this application: The comprehensive ‘robot library’ allows users to program their cobots directly within the TIA Portal via a unified user interface and to include them in their planning, which will now also include UR’s collaborative robots, greatly extending the range of companies benefitting from the cobot technology: Across industries, users will now encounter the UR cobots in the context of complete plant engineering solutions.

“We are welcoming Universal Robots as a new partner just in time for the start of the new Simatic Robot Library’s piloting,” says Tobias Fengel, Marketing Manager at Siemens Digital Industries. “We are delighted that we will soon be able to offer our clients a forward-looking solution together with the cobot market leader.”

Thanks to the TIA portal’s integrated design, users can now independently implement the UR cobots within major production lines and teach them functions such as jog mode or path point creation. The new comprehensive library allows users to download programming examples and use them to control the UR cobots.

“Our cobots have always been characterised by their intuitive handling,” Mark Gray explains. “Their integration into the TIA portal via the Simatic Robot Library now accelerates their integration and implementation into complex production lines. It also makes it easier to combine the UR cobots with technologies like Edge data analyses or cloud services and include them in the monitoring of plant conditions.”