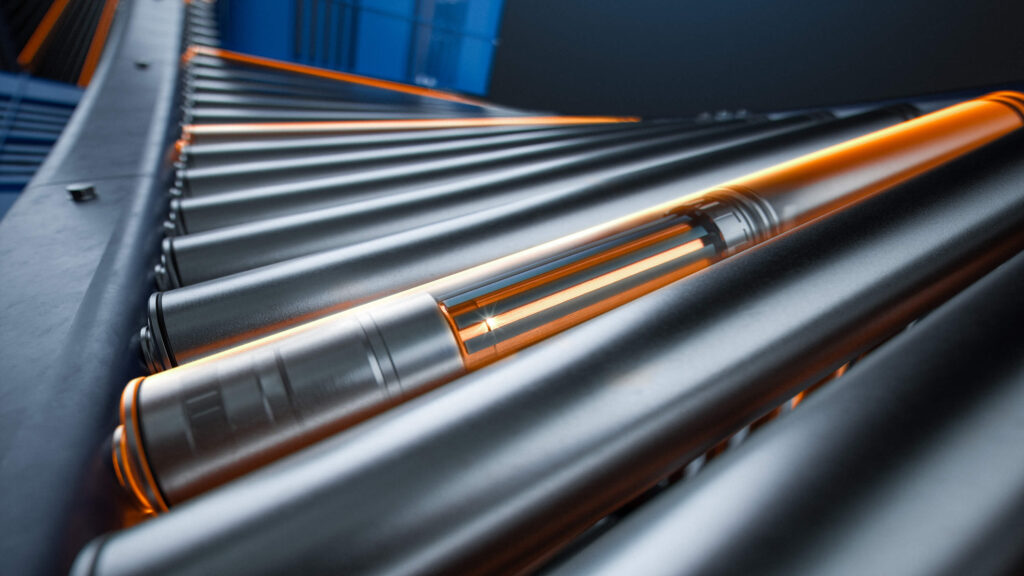

Powerful Motor Driven Roller Launched

18th April 2024

Less complexity, fewer variants, more efficiency, more power and simpler, faster commissioning, and maintenance. Lenze is driving the future of conveyance with a revolutionary new magnetic motor driven roller (MDR) to support intralogistics customers. The o450 MDR will integrate directly into existing conveyor systems and deliver an output of 115 watts, making it more than twice as powerful as comparable systems on the market. Thanks to the vernier principle, the MDR is pleasantly quiet in operation. With energy savings of 30 percent compared to conventional motor driven rollers, it also impresses in terms of sustainability. Visitors to LogiMat in Stuttgart saw this product in action.

Due to the unique design, this motor has significantly lower copper and iron losses overall, which means that less heat is generated within the roller. This results in a positive effect regarding efficiency as cooler copper windings have lower resistance (and therefore lower copper losses). The cooler magnets have a higher magnetic flux linkage and can therefore achieve the same torque with a lower current. Depending on the speed, the MDR would therefore fulfill efficiency classes IE7 – IE9 and the customer saves up to 30 percent energy compared to conventional systems. An example: in a logistics centre with 20 km of conveyor line and 20,000 motor driven rollers from Lenze in use, savings of up to 335 MWh of electricity or 145 t of CO2 would be possible.

The o450 from Lenze can handle up to 30kg. Even at low speeds, it offers the full nominal torque, which is hugely advantageous for accelerating conveyed goods.

Motor driven roller with 24 V or 48 V

The motor transfers its rotational energy via its rotor directly to the conveyed goods or the conveyor belt. The motor is based on the Vernier principle and combines a 3-phase AC motor with a loss-free magnetic gearbox. The advantage over a conventional drive system is that the motor roller operates at 24 V or 48 V, which means non-electricians can replace, maintain, or install the roller. As there are no moving parts apart from the bearings and the usual gearbox noises are eliminated, the o450 is exceptionally quiet. This also increases the attractiveness of working in a warehouse.

Variances are also reduced by 85 percent with this gearless MDR. This minimizes design resources while minimizing excess inventory in a warehouse. Competitors currently have up to ten different gear ratios in their portfolio, according to Lenze.

In addition, the cabling effort is also significantly reduced. While comparable products require cables for speed and temperature monitoring in addition to the power connection, the latter two are integrated into the roller of the Lenze o450.

read more