New Particle Sensor Monitors Dust, Soot and Smoke

12th April 2017

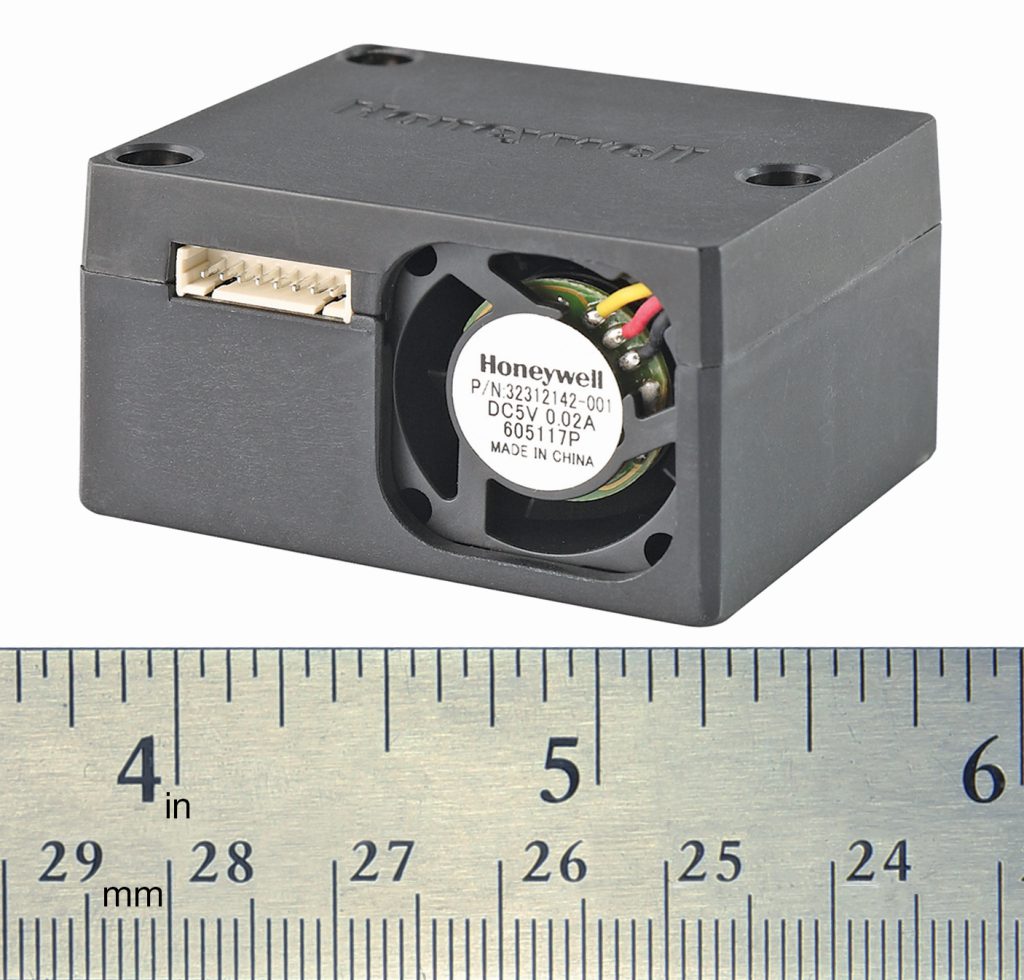

Honeywell has launched a new particle sensor designed to help building owners and consumers monitor the air for potentially harmful particulate contaminants caused by dust, soot and smoke.

Honeywell’s HPM series particle sensor is designed to work in heating, ventilation and air conditioning (HVAC) systems and consumer products such air purifiers to measure air quality in homes, buildings and public spaces. The sensor has already been incorporated in Honeywell’s new PM2.5 Indoor Air Quality Detector, a portable air monitor for consumers in China.

“Particle sensors play a critical role in measuring and managing the quality of the air we breathe to help protect our health,” said Graham Robinson, president of Honeywell’s Sensing and Internet of Things business, a leader in sensor technology for industries ranging from health care to aerospace. “Honeywell leveraged decades of expertise in sensing technology and connected solutions to develop this state-of-the-art, affordable sensing solution to help prevent building occupants from developing health issues that could be caused by poor air quality.”

The new sensor can be used in a range of consumer products such as air purifiers, automotive air systems and mobile air quality detectors. The sensor uses laser technology to accurately and cost-effectively monitor for fine inhalable particles that are 2.5 micrometers in diameter or smaller. For reference, the average human hair is nearly 30 times larger at 70 micrometers in diameter.

According to the U.S. Environmental Protection Agency, fine particles, which are often caused by burning fossil fuels, can settle deep into lungs or even enter the bloodstream and pose health risks.

The sensor outputs an electrical signal that can be fed into HVAC control systems in buildings and homes or into other air monitoring devices. This information can alert building operators that air purification systems should be activated or if outdoor air could be used to improve indoor air quality, or when an air filter needs to be changed or early maintenance should be performed on indoor air delivery systems.

The laser-based sensor uses a light-scattering method to accurately detect and count particles in the concentration range of 0 micrograms-per-cubic-metre-of-air (µg/m3) to 1,000 µg/m3 in a given environment. The sensor then analyzes the particulate size and concentration in real time to enable systems to provide alerts and allow operators to take remediation actions. With its heavy industrial level electromagnetic compatibility, the HPM series sensor performs accurately in harsh, challenging environments. Building operators benefit from the sensor’s industry-leading long life of 20,000 hours, which allows for stable operations and continuous use.

The sensor can work with HVAC and building management systems like those from Honeywell Home and Building Technologies, which creates products, software and technologies found in more than 10 million buildings worldwide to increase operational and energy efficiencies.

Honeywell’s Sensing and IoT business, part of Honeywell Safety and Productivity Solutions, helps original equipment manufacturers enhance the precision, repeatability and durability of their products with custom-engineered sensors, switches and machine safeguarding. Honeywell offers more than 50,000 solutions that are featured in products ranging from breathing machines and airplanes to oil rigs and construction equipment.