Intralogistics Performance is Paramount

15th January 2024

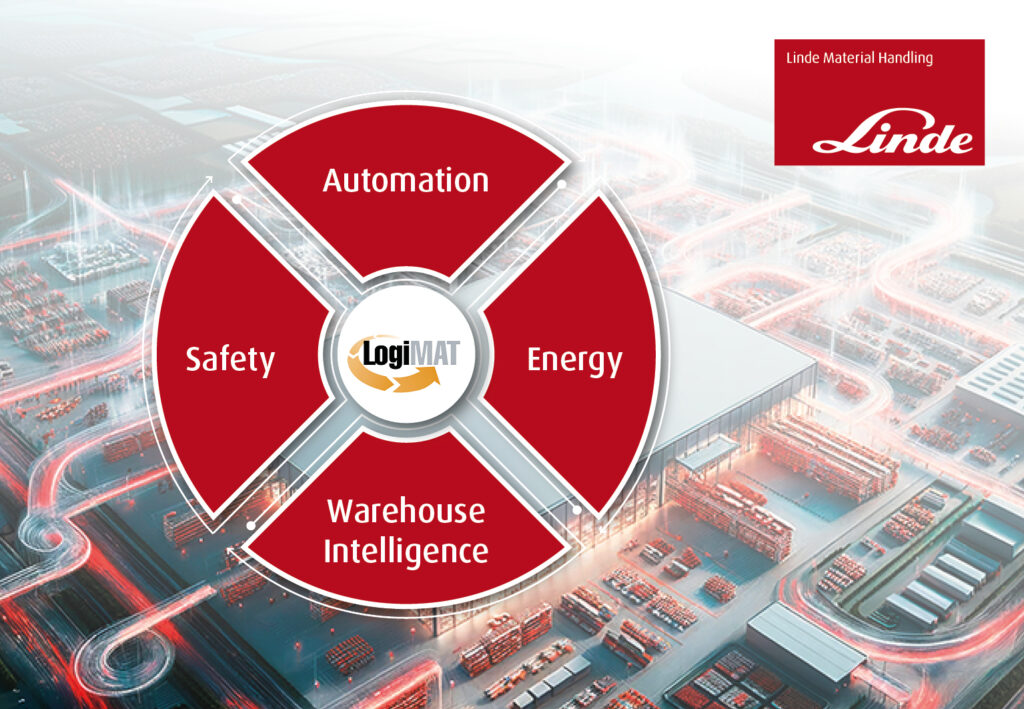

Automation solutions offer enormous potential when it comes to internal material flow. At this year’s LogiMAT trade show in Stuttgart, Germany, Linde Material Handling (MH) will be demonstrating the options available to small, medium-sized and large companies and showing how a wide range of project requirements can be successfully implemented. Energy, Safety and Warehouse Intelligence will be further key topics in focus at the centrally located exhibition booth in Hall 10. Offering the broadest portfolio of energy and safety options for industrial trucks and leading technical material flow solutions, the intralogistics specialist supports its customers on their way to greater efficiency, sustainability and performance.

Occupying more than 500 square meters, Linde MH’s main booth in Hall 10 (Booth B21 and B17) highlights current trends in intralogistics: Automation, Energy, Safety and Warehouse Intelligence. On display will be corresponding products and solutions which are designed to optimize the internal material flow. A live demonstration will showcase flexible and scalable automation solutions involving automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). Just a few meters away from the exhibition stand, in the loading yard between Halls 8 and 10, visitors can test forklifts for themselves or get an up-close look during vehicle demonstrations. Examples include various reversing assistance systems, such as the AI-based Reverse Assist Camera, that alert industrial truck drivers to people in the vicinity behind them. Additional exhibition space that offers hands-on experience with various vehicle models is located in the outdoor area between Halls 9 and 10.

“The Linde brand represents top performance in goods handling. This is achieved through innovative products and solutions, a high level of user-friendliness, a wide range of active and passive safety and assistance systems, customized individual solutions and the comprehensive consulting expertise of our sales organization. Our products and solutions ensure maximum productivity even under the most demanding operating conditions, such as those found in the beverage, paper, wood, food and chemical industries,” says Torsten Rochelmeyer, Senior Director Strategy & Solution Portfolio at Linde MH.

At LogiMAT 2024, Linde MH will showcase its expertise as a competent partner for the automation of material flow processes. “Together with our network partners, we have successfully planned and implemented hundreds of projects in recent years,” reports Rochelmeyer, referring to the sales organization’s extensive expertise and experience gained in small and large projects alike. Alongside this, standardized solution packages are available for simple transport tasks. “This allows existing brownfield processes in particular to be automated more quickly,” says the Linde trade show manager. The company’s automation experts can resort to a large product portfolio when it comes to implementing projects: The range extends from AMRs such as the Linde C-MATIC and the Linde C-MATIC HP, to automated pallet stackers (Linde L-MATIC) and tow tractors (Linde P-MATIC) all the way to reach trucks (Linde R-MATIC) and VNA trucks (Linde K-MATIC). Where complex automated material flow systems are required, colleagues from the Group’s sister company Dematic will be involved, whose booth in Hall 10 is directly adjacent to the Linde MH area.

The Energy area of the exhibition covers the company’s broad spectrum of available energy types, with a focus on the X-series electric counterbalanced trucks with lithium-ion batteries. They are just as powerful, robust and ergonomic as ICE-powered trucks, but are emission-free and potentially CO2-neutral in operation. However, diesel, LPG, CNG, lead-acid batteries, fuel cells and HVO (Hydrotreated Vegetable Oil) are also available as power options. “Visitors who want to find out about suitable energy systems for their current or future fleet will be offered software-assisted advice that provides an initial assessment based on the requirements, general conditions and customer-specific situation. This can be followed by further analysis within the company,” explains Rochelmeyer. Another focus will be on the Linde connect fleet management system. In addition to access control, damage monitoring, vehicle and driver management, fleet usage analysis and predictive maintenance, the Linde connect:charger software module provides intelligent control of battery chargers, helping to avoid expensive power peaks.

In general, the following applies to all warehouse activities: The safer the internal material flow, the higher the productivity and thus the contribution to the company’s success. Using a reach truck equipped with extensive safety features, Linde MH demonstrates how fleet operators can ensure smooth processes and protect their employees. The features range from a large number of driver assistance systems such as the Linde Safety Guard for the mutual warning of pedestrians and drivers and the Rack Protection Sensor for avoiding collisions with racks and goods to various lighting solutions and protection systems like the Dynamic Mast Control system for reducing mast vibration.

In the Warehouse Intelligence area, guests can learn how to make their warehouse even more efficient and dynamic with the help of modular software solutions. An application consisting of a warehouse management system, a forklift guidance system and a warehouse control system provides real-time visualization of the warehouse through a three-dimensional view and shows the driver the fastest route to the destination. In the process, it automatically tracks the movements of the load carriers across changing storage locations, which ensures a high degree of transparency. The software is also capable of integrating and controlling various automated systems such as AGVs and shuttles.