Gebhardt Shuttle System Aims to Boost Warehouse Capacity and Efficiency

15th April 2019

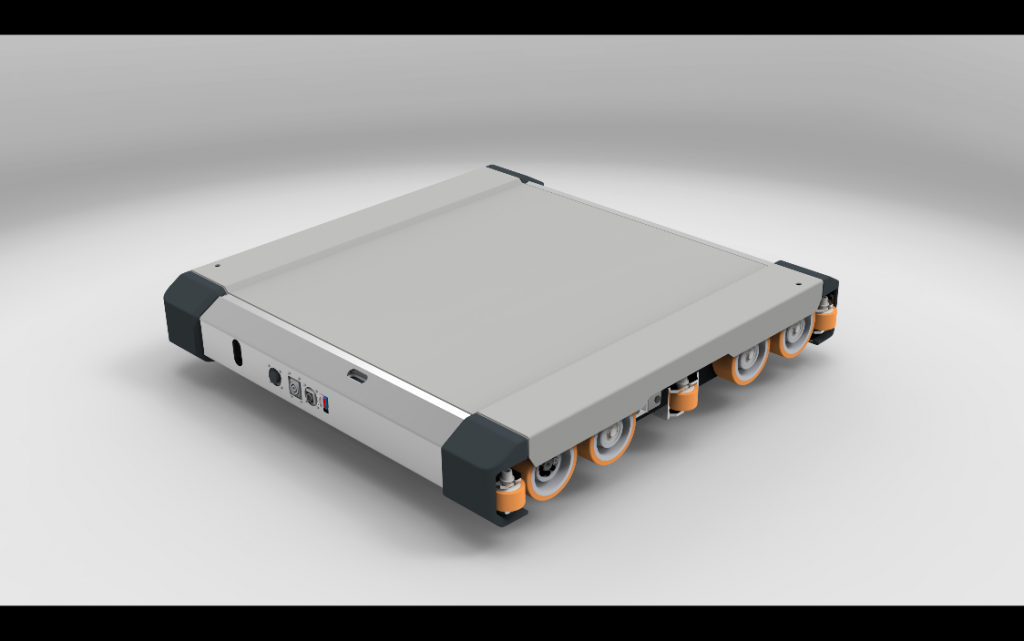

Automation specialist Gebhardt says its Shuttle StoreBiter 500 is the new benchmark when it comes to warehouse capacity, flexibility and efficiency with the storage of pallets, box pallets and containers.

The shuttle vehicle itself performs the function of a load handling device. The flat lifting shuttle can transport the conveyed goods in passively arranged, multi-deep storage channels and set them down in their correct locations. One of the key benefits of the StoreBiter 500 is its autonomy, which allows it to move fully independently throughout the storage channels, says the company.

The StoreBiter 500 can be combined with an AS/RS crane such as the Cheetah heavy, a Cross Conveyor or a Vertical Conveyor. The shuttle itself is piloted through the warehouse by a PLC and supplied with energy via Supercaps. This facilitates storage channels of arbitrary lengths without complex, interference-prone cables and rope connections. Charge stations are mounted on the carrier vehicle and can be additionally installed in the storage channels if required. With this, the StoreBiter 500 is designed for 24/7 operation as the batteries do not require protracted recharging.

The StoreBiter 500 shuttle system stands out due to the high storage capacity with comparatively low investment and operating costs. The passive storage channels and simple, robust engineering of the shuttle result in low maintenance and servicing costs. The system design enables rational, requirement-orientated IT organisation and inventory monitoring. The warehouse system itself operates in accordance with the Last-in-First-out principle. The StoreBiter 500 is the optimum solution when it comes to space-saving warehouse storage for a large number of pallets. The advantages of the system are even greater if the storage channels can be filled on an unmixed basis.