IFOY Test Report: ff Fördersysteme

2nd June 2023

It’s the turn of ff Fördersysteme’s 3D conveyor and drive system in the spotlight as we continue our run-through of all the IFOY Award finalists ahead of the announcement ceremony in Dortmund on June 22nd.

Category: Start-up of the Year

IFOY Test Report

ff Fördersysteme offers a flexible basic system for conveyor and transport systems of all kinds. On the basis of a three-dimensionally movable chain and a guide system consisting of straight and curved segments, conveyor sections that are precisely adapted to the respective requirements can be implemented without interfaces in the smallest of spaces. By adapting the system with various transport drivers, it is suitable for a wide variety of applications.

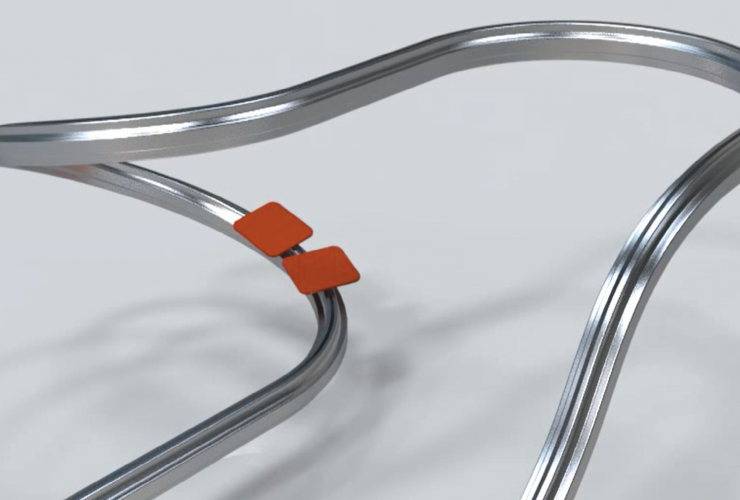

The basis of the conveyor system is a patented, three-dimensionally movable drive chain. The free movement of the chain is made possible by an axial axis of rotation. In contrast to conventional conveyor chains, this 3D chain can thus twist on a helical path and run straight into it on a continuing path. This allows the conveyor chain to follow any guideway and curvature in space.

The chain consists of two chain links, which are connected to each other by means of an axial pin. These links can be manufactured in different sizes and materials depending on the requirements. The chain is guided in an aluminium profile. This profile is open on one side so that a carrier for the transported material can be placed directly on the conveyor chain. The load is transferred via the guide rail.

The modular 3D chain drive system consists of straight and curved components that can be flexibly linked together, allowing a system to be converted or retrofitted as required. This allows the tightest radii and any inclines to be mastered and the shortest possible conveying distance to be realised. No interfaces, interruptions and associated drives, sensors, etc. are necessary. By attaching different transport carriers such as conveyor belts, plastic boxes, overhead conveyors and possibly even a lightweight robot, the system can be used in a wide variety of ways. The technology thus also offers the possibility of converting an existing conveyor system or managing an entire production process with a single basic system.

Innovation: The simplicity, flexible use by means of different transport attachments and the three-dimensionality of the system are particularly noteworthy. Most conveyor lines, with curves, ramps, elevators, etc., consist of a large number of combined modules. Each module usually has its own drive and sensors. This results in numerous transfer points and all drives must be integrated into one control system. Gradients are often only possible to a limited extent.

The ff conveyor sections consist of a single drive train, which can be designed three-dimensionally in space as required and can be linked to various transport attachments. Whether transporting, tilting, swivelling, rotating: various tasks can be solved in one track. 3D systems offered on the market do not offer full freedom of movement and are also mostly designed for a specific application. This opens up new possibilities in plant design with ff conveyor systems. An example application could be a spiral conveyor that can travel up a transport path once and back down again in the same piece. This endless loop allows such a system to serve once as a buffer, packages can be fed in, but also removed again. This results in enormous space savings.

Market relevance: The 3D chain drive offers a technical and economic alternative in many areas. For example, the system can be used in the industrial sector, but also in passenger transportation. In the field of passenger transportation, this technology can be used as a new drive technology for a three-dimensional escalator.

Main advantages for the customer: ff Fördersysteme offers a basic system for installations that are not only designed and built for a specific purpose. Flexible adaptation allows them to be converted to meet a wide variety of requirements – today transporting battery components, tomorrow parts for a hydrogen drive. The three-dimensional mobility eliminates the need for a modular design of a conveyor system. This results in significantly reduced engineering and equipment requirements with enormous cost and resource advantages. The possibility of new routing also offers additional space advantages. Last but not least, the assembly, installation and maintenance effort is low.

IFOY test verdict: ff Fördersysteme offers a flexible basic system for conveyor and transport systems of all kinds. Based on a three-dimensionally movable chain and a guide system consisting of straight and curved segments, conveyor lines precisely adapted to the respective requirements can be realised in a very confined space without interfaces. The adaptation of the system with various transport carriers makes it suitable for a wide range of applications.

IFOY Innovation Check

Market relevance: Optimally suited for complex existing buildings due to the very flexible geometry and the high number of degrees of freedom. However, it is certainly not a standard solution for every application. In the environment of limited space, for example for future urban solutions, certainly of importance, but also here dependent on the price. The envisaged area of passenger transportation also sounds particularly interesting, although this is not yet described further in conceptual terms.

Customer benefit: All spatial directions and even a rotary movement around its own axis can be implemented. This means that a high degree of space economy can be achieved. Furthermore, the chain and the chain carrier can be designed for virtually any application. This means that practically any load carrier is possible in the field of small load transport. Possible applications can be found in various industrial sectors, both as a pure drive element in multidimensional conveyors or, with the appropriate load carrier, as an independent conveyor system.

Novelty / Innovation: Very good, patented idea for driving multidimensional conveyors with a maximum number of degrees of freedom. Due to the special design, the drive motor can be accommodated almost anywhere, drives positively and almost without polygon effect. This results in very smooth running for a chain conveyor. The design itself is a clear leap forward in innovation, but the application and available construction kit has yet to be developed. It should be possible to cover long distances with a closed drive train, although the maximum lengths that can be implemented have not yet been described in detail.

Functionality / Type of implementation: Since this is a start-up category, the idea has so far only been implemented as a prototype, and the chain guide has been realised as a 3D print. Even as a prototype, the high-quality, robust design is clearly evident, which is also suitable for dynamic and demanding industrial use and certainly ensures a long service life with all its flexibility.

Verdict: Nice, purely mechanical idea, which can certainly offer great advantages for specific applications due to the very flexible geometry. However, the cost side is quite little known, also the performance can only be estimated. The product is still at a very early stage. The innovative leap is definitely neatly present in the mechanical area, but as an overall system it is still difficult to estimate.

Market relevance Ø

Customer benefit +

Novelty / Innovation +

Functionality / Type of implementation +

[KEY: ++ very good / + good / Ø balanced / – less / — not available]