Automated Packaging System “Eases Warehouse Social Distancing”

15th June 2020

Social distancing in warehouses can be facilitated by a new automated packaging system, says its manufacturer.

Duncan Hall, UKI APS Commercial Leader at Automated Packaging Systems says businesses are tackling social distancing in several ways.

“Some businesses are reducing staff and limiting production, others are leasing additional space, paying staff to work additional hours, or rearranging their warehouse, but all of these cost the business money without adding value.”

“Social distancing has had a big impact on the logistics of ecommerce businesses and there is only one solution that can help, and that is to introduce automation. Automation can reduce the number of people required in one particular area while increasing the efficiency of the operation, thus adding value.”

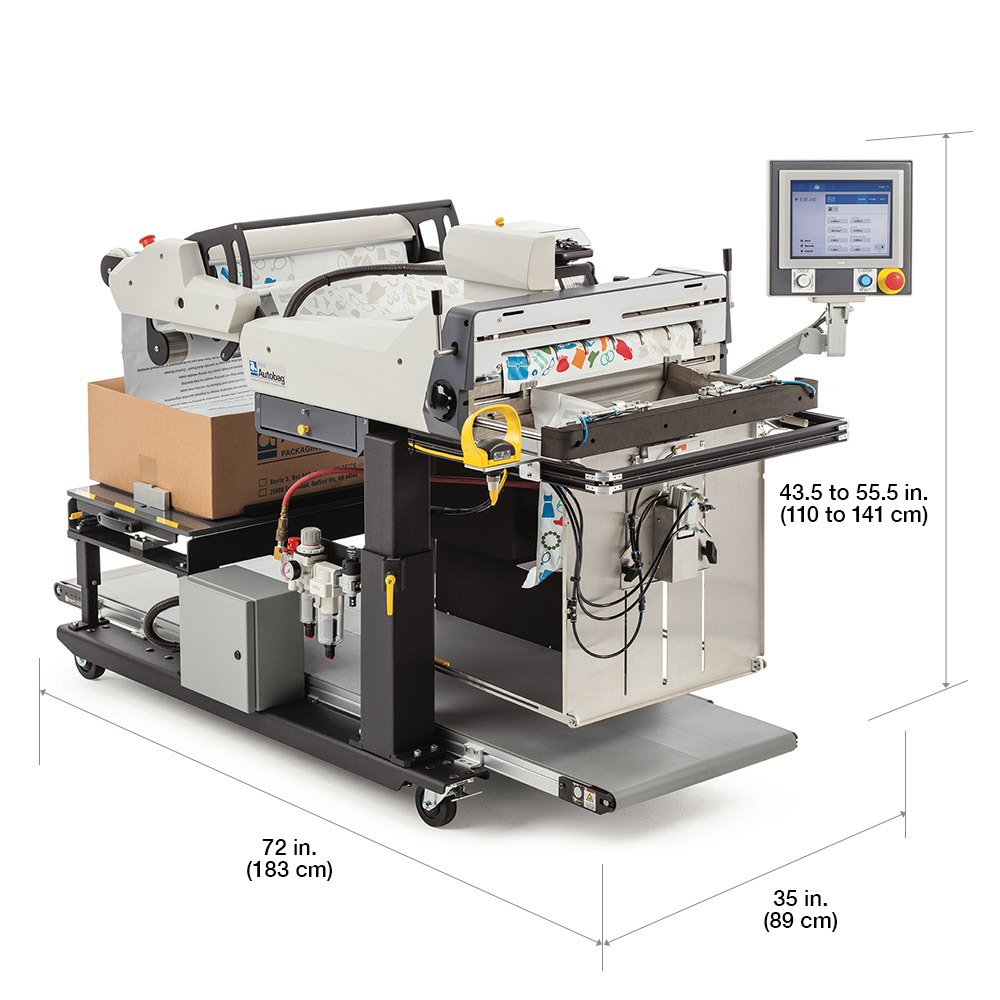

He claims: “The Autobag 850S, manufactured by Automated Packaging Systems for example, has roughly the same footprint as one manual packaging bench but can produce the equivalent number of orders per hour as four manual packaging benches, the Autobag 850s therefore allows ecommerce businesses to maintain social distancing while achieving a greater level of efficiency at the same time.”

“With the Autobag 850S, or similar automated machinery, businesses can increase their production volume and meet the increase in demand for their products, rather than limiting them. There will also be significant saving on labour costs.”

“In addition, introducing automation in your warehouse does not have to mean significant integration projects. The Autobag 850S is easily installed and rarely requires significant changes to the warehouse management system,” Duncan says.

Fanatics is a global supplier of sports fan merchandise. From its warehouse in North Manchester, an average of 7,500 items are dispatched every day to meet demand from its popular website. This rises to approximately 28,000 orders a day during peak periods.

Fanatics Operations Manager, Andrew Crozier says they have introduced Autobag 850S mail order fulfillment bag packaging systems to automate and streamline its complex, high volume, mail order processes.

“Prior to the introduction, most of our warehouse was handled manually with operatives working at eight benches, packing all items by hand, and manually printing labels and invoices on two separate printers. We approached Automated Packaging Systems for a solution to automate much of the packaging process to help save space and increase the number of orders one operative could pack every hour,” Andrew says.

The Autobag 850S machines feature ‘grip open’ and ‘grip seal’ technology which automatically opens and seals the mail order bag to allow operators to quickly pack orders. The Autobag 850S machines at the Fanatics Manchester warehouse has enabled the company to keep pace with its fast-growing order book and optimize the space available to them in their outbound packing department. “Packing operatives processed between 45 and 50 orders per hour under the old manual system, now that figure has increased to 200 – 250 packages per hour,” Andrew says.

Automation will provide the answers for E-commerce operations that are looking to meet the needs of increased demand whilst prioritising the safety of their staff.