Work underway on ‘next-generation’ HGV hydrogen engine

25th February 2022

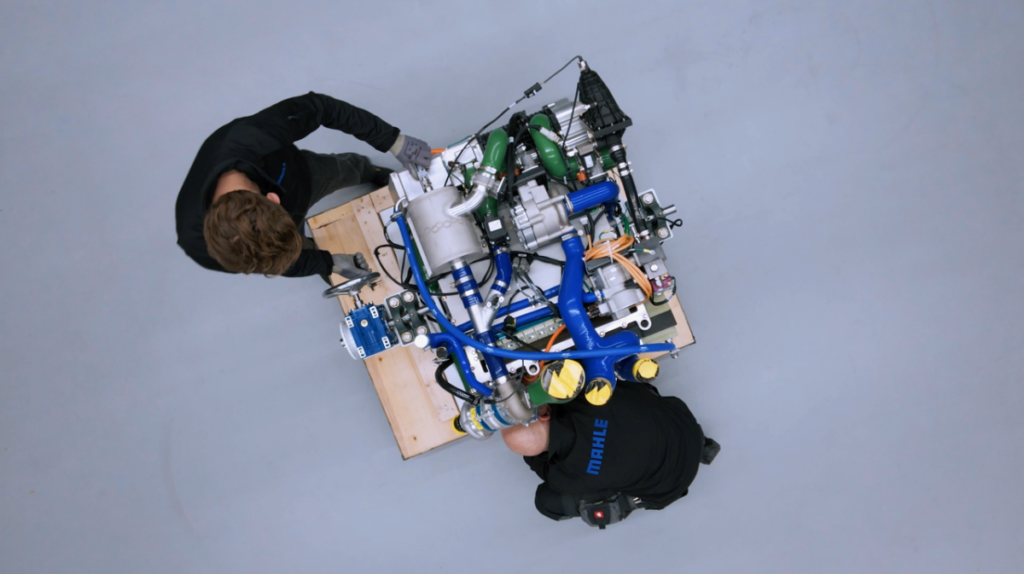

Ballard Power Systems and MAHLE Group, a Tier 1 automotive supplier, are progressing the development of a new fuel cell engine concept for long-haul trucks, with MAHLE taking delivery of 120kW module at the company’s hydrogen test centre in Stuttgart, Germany.

The new concept engine is a part of the ongoing development of Ballard’s future product platform – which will feature power outputs from 180kW to 360kW – to specifically address the requirements of heavy-duty and long-haul trucks on global markets.

The joint project is a multi-year development program in which Ballard and MAHLE will continuously refine Ballard’s compact, energy-dense fuel cell stack and an integrated engine to meet the quality and performance expectations of the truck industry.

Seungsoo Jung, Product Director, Trucks, Ballard, said: “We are committed to fuel cell technology leadership, and to tailoring our fuel cell solutions to our customers’ needs. We are extremely optimistic about the value of our collaboration with MAHLE—combining their strength in the automotive value chain with our leadership in hydrogen fuel cell technology and products.”

The module incorporates Ballard’s FCgen-HPS Fuel Cell stack, which addresses limited engine space, and maximizes freight and cargo capacity. Based on an earlier high power density design, the technology draws on Ballard’s on-road experience of 100 million km in service and proven fuel cell durability, exceeding 30,000 in vehicle operation as demonstrated in the London bus fleet.

The concept fuel cell module is the central building block in Ballard’s future engine, which MAHLE will now test and integrate with their components, including the balance-of-plant, thermal management and power electronics, and the system assembly.

The new concept engine for heavy-duty vehicles will feature:

High Power for Heavy Payloads: the 120kW module is a building block for systems that can deliver up to 240kW power, to serve the needs of heavy Class 8 and long-haul freight trucks and coaches that require more power and longer range than transit buses or short-range delivery vehicles.

Easier Maintenance for Lower Total Cost of Ownership (TCO): the module design features reduced weight, fewer parts and a more compact design. A key new feature, the “Open Engine Concept Design”, provides better access to parts and the subsystem, for easier maintenance and ultimately, a lower total life cycle cost.

Robust, Reliable Design: For long-haul trucks delivering critical goods, reliability and robustness are essential – and the Concept Engine’s reduced parts count and simplified integration design are key factors in dependable long-term performance.

Trustworthy Durability: The Concept Engine is based on field-proven technologies and designs, and Ballard’s vast experience in heavy-duty transport.

Fuel Efficiency for Economical Operation: Fuel costs are a major component of a Class 8 truck’s TCO. Fuel efficiency is also key for a manageable heat rejection system.

Freeze Start for Cold Weather: Because commercial trucks have to power up and deliver the goods, even in midwinter in the worst mountain roads.

The partnership’s aim is to accelerate the development and commercialization of zero-emission fuel cell systems. Ballard has prime responsibility for system design and the fuel cell stack sub-system, while MAHLE’s scope of responsibility includes balance-of-plant components, thermal management and power electronics for the complete fuel cell system.