Artificial intelligence is no longer a futuristic concept — it’s a driving force transforming how goods are stored, moved and managed. From predictive analytics to self-learning systems, AI is enabling a new era of intelligent logistics. Mecalux, a provider of intralogistics solutions, is at the forefront of this transformation, embedding AI across its warehouse management software and robotics systems to deliver smarter, more adaptive supply chains.

Turning data into decisions

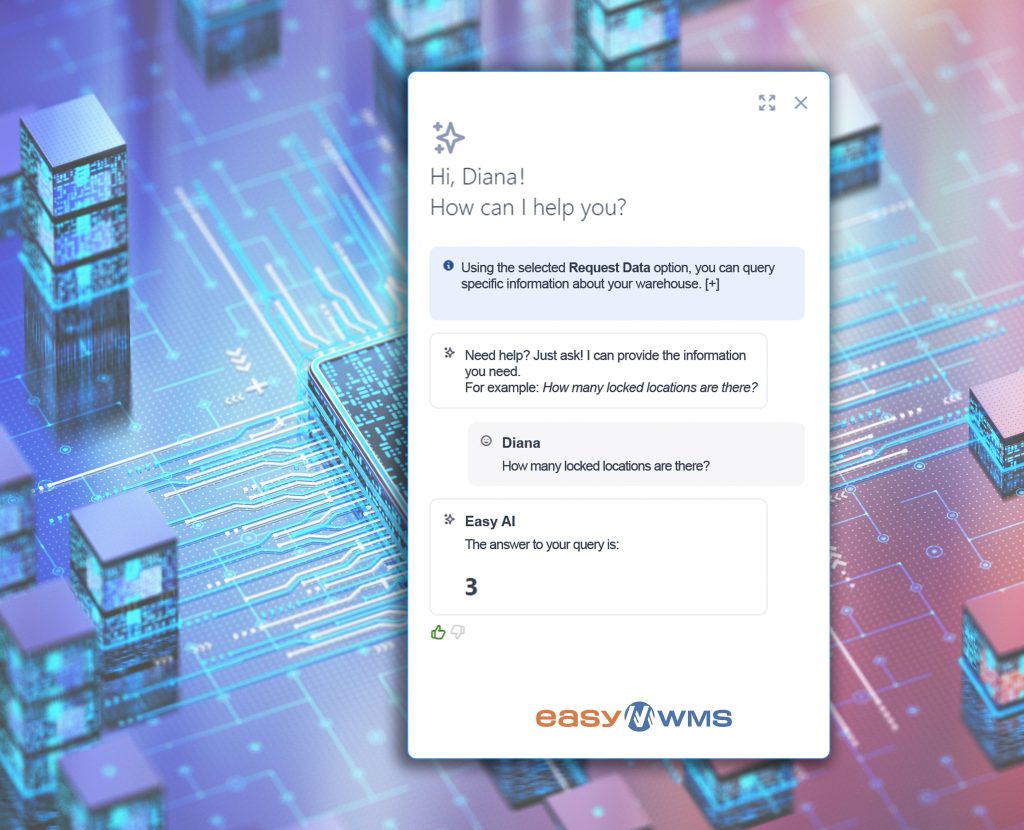

Mecalux Software Solutions has taken a bold step forward by integrating generative AI into its flagship warehouse management system, Easy WMS. Deployed in over 1,100 facilities worldwide, the software now enables users to interact with the system naturally, in seven languages, through an intuitive chat interface. Managers can ask, “Which products are nearing stockout?” or “Show me today’s picking efficiency,” and receive real-time, data-rich answers.

This conversational capability goes far beyond convenience. Easy WMS’s AI assistant can generate KPI dashboards, reports, custom views and even execute specific actions such as releasing orders or unlocking aisles — all within seconds. By learning from every interaction, the system continuously refines its responses, helping teams make faster, more accurate decisions.

Mecalux is also applying this technology internally. Its Easy Builder development platform and AI web portal for programmers empower engineers to code, debug and document software more efficiently. These innovations improve software quality, accelerate development and strengthen Mecalux’s ability to deliver ever more sophisticated logistics solutions.

AMRs with collective intelligence

Automation is evolving rapidly from static systems to autonomous intelligence. Mecalux’s research into automated mobile robots (AMRs) is pioneering this shift. Traditional AMRs rely on predefined routes, which can cause bottlenecks and limit flexibility. Mecalux is developing AI-driven free navigation, where robots learn to adapt dynamically, avoiding obstacles, optimising paths and coordinating seamlessly with humans and other machines.

Through simulation and digital twins, engineers test these algorithms in virtual environments before deploying them in real facilities. The goal: to build swarm intelligence — a network of self-learning robots capable of acting as a collective, predicting demand changes and optimising resources in real time. This next generation of autonomous robots will dramatically enhance warehouse resilience and performance.

Innovating with MIT

To accelerate innovation, Mecalux has joined forces with the Massachusetts Institute of Technology (MIT) to establish the Intelligent Logistics Systems Lab at the MIT Center for Transportation & Logistics. This collaboration explores the use of machine learning and reinforcement learning to revolutionise distributed order management (DOM) systems.

Led by Matthias Winkenbach, the initiative focuses on developing orchestration models that replace static rules with self-learning AI capable of adapting to shifting demand, capacity and delivery constraints. By leveraging simulations, these models can test thousands of scenarios safely and efficiently.

Towards a new era of intelligent logistics

Across its software, automation and research initiatives, Mecalux is redefining how intelligence operates in the warehouse. Its approach combines cutting-edge AI, robust engineering and academic collaboration to design systems that think, learn and evolve.

From predictive order management to autonomous robotics, Mecalux’s innovations represent a clear vision of the warehouse of the future — one where humans and machines collaborate seamlessly to achieve unprecedented efficiency, accuracy and sustainability.