Hubtex has updated its modular development platform for electric multidirectional sideloaders – the largest in the industry – with its new PhoeniX range. The PhoeniX series will gradually replace all vehicles based on the ESTL platform. The first two models, with a load carrying capacity between three and five tonnes, will be demonstrated at Ligna Hannover (27-31 May 2019). Trade fair visitors can head to booth N65, west of Pavilion 33, to see the benefits of the new PhoeniX for themselves. The vehicles feature a highly ergonomic cabin and also offer optimal manoeuvrability and improved all-round visibility. The multi-way trucks are also Industry 4.0 compatible thanks to the new control system, giving the PhoeniX all the tools it needs to meet future requirements.

As with MaxX vehicles, drivers benefit from an optimally designed cabin in terms of ergonomics. Generous space and a lot of legroom mean maximum comfort for drivers. The new cabin also offers improved all-round visibility, especially past the right fork. The HIT3 operating terminal is equipped with a colour display that gives drivers a clear picture of all important settings and operating data. Additional functions were added to the HIT3 terminal for the new vehicle series. During development of the new PhoeniX series, the transverse cabin and all other cabin variants will be implemented over the course of 2019.

New platform with additional equipment

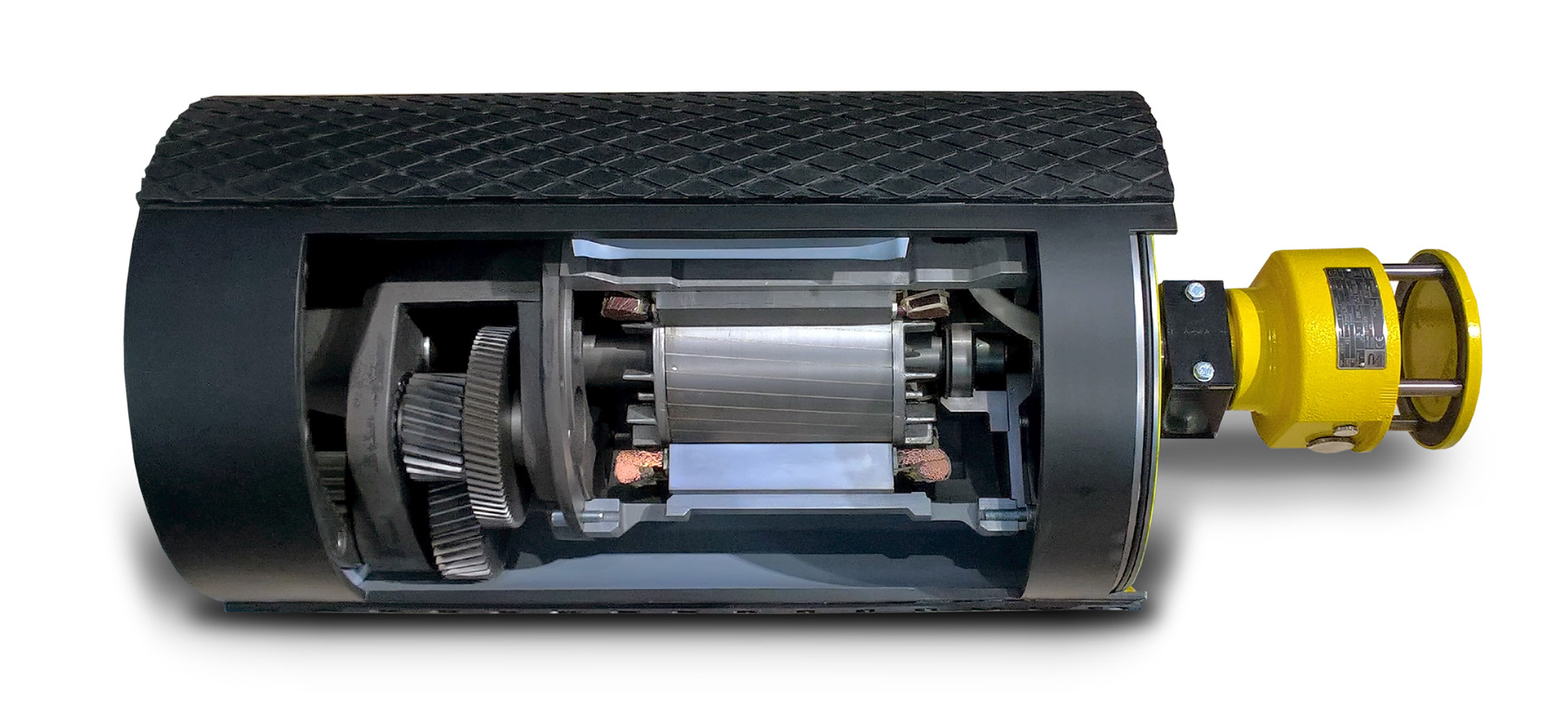

The PhoeniX development platform is the first to feature purely electric power steering for an entire platform. This means that steering noises are kept to a minimum, while also significantly reducing energy consumption. Users can achieve major efficiency gains by combining this steering system with inductive wire guidance. Equipped with the patented HX steering system as an optional extra, the forklift offers perfect manoeuvrability in all directions. Furthermore, Hubtex has further enhanced the smooth operation of the lifting mast, minimising vibrations and ensuring precise load handling. In this field of application and if required, the new electric multidirectional sideloader also features a weight and overload display independent of the lift height.

All set to meet future requirements

Even the standard version of the PhoeniX is already designed for gradual automation. A new generation of vehicle control system, pre-planned paths for cabling, positions for sensors and additional features underline the development platforms future-oriented design. If required, numerous assistance systems can also be integrated, such as laser-guided navigation, which will be available in the PhoeniX series for the first time. This new system ensures extremely precise vehicle positioning. “At Hubtex, decades of experience go into redesigning and further developing our tried-and-tested electric multidirectional sideloaders,” explains Hubtex Managing Director Hans-Joachim Finger. “We’re doing the right thing at the right time to ensure we are in the best possible position to meet the growing requirements in the Industry 4.0 era.” By developing the new PhoeniX platform, Hubtex is strengthening its portfolio of electric multidirectional sideloaders. Together with the MaxX and BasiX platforms, the company can now offer the right solution for any application in the handling of long goods.

All information on Hubtex’ appearance at the 2019 Ligna trade fair can be found at https://messen.hubtex.com/en/homepage/