Eighty-five percent of logistics leaders expect that their outsourcing budget will increase by more than 5% in 2020, according to Gartner, Inc. Already for 2019, 85% reported a similar budget increase.

“Outsourcing one or more logistics service types has become largely mainstream,” said Courtney Rogerson, senior principal analyst with the Gartner Supply Chain Practice. The question no longer is whether to outsource, but what and how much to outsource. Evaluating different outsourcing strategies has become a priority for logistics leaders.”

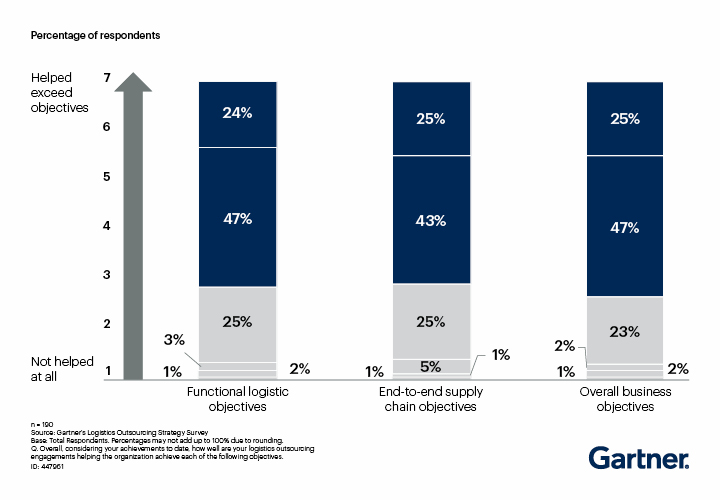

Based on the Gartner 2019 Logistics Outsourcing Strategy Survey, one reason for the expected budget increase is that logistics outsourcing supports the business. Approximately 70% of respondents stated that functional, end-to-end (E2E) supply chain and overall business objectives have been met or exceeded with the help of logistics outsourcing counterparts, such as third-party-logistics providers (3PLs).

Technology, Speed and Visibility are Top Priorities

To be effective, the logistics outsourcing strategy needs to be aligned with the overall logistics priorities. Almost half of surveyed logistics leaders stated that updating their technology systems, increasing speed to customer and improving visibility are their most important goals for next year.

“Those priorities show that we are in the thick of the digital era. New routes to market and technology enabled products and services are rapidly disrupting industries and business models,” Ms. Rogerson explained. “To respond to these accelerated and evocative changes, logistics leaders need not only understand the foundational elements of good overall strategy, but also rethink how their logistics outsourcing strategy is assessed and developed.”

“For example, leaders can increase the iterative frequency of strategic planning across multiple time horizons. Rather than treating the outsourcing strategy solely as an annual process, they should include mechanisms, techniques and open communication channels for continuously capturing issues, ideas and insights that will increase the contribution of logistics outsourcing towards meeting the overall business goals.”

While logistics outsourcing is seen as helpful by a majority of logistics leaders, there are also risks and challenges. The complexity of working with multiple partners is the most mentioned challenge, followed by cybersecurity concerns and the incompatibility of information systems between different 3PLs and the organization.

“Low maturity organizations often outsource logistics with unrealistic expectations regarding ROI and service levels,” Ms. Rogerson said. “Outsourcing can help make your organization more efficient, but it requires a high degree of coordination. Make sure you have the appropriate resources and skills at your disposal.”