Tesco, the largest retailer in the United Kingdom (UK) and one of the world’s leading international retailers, has expanded its UK delivery fleet adding 52 new vans with inverter driven, full electric E-200 refrigeration units from Thermo King.

Tesco wanted to increase the sustainability and flexibility of their dot-com vehicles operating diverse home delivery, rural and click-and-collect services. They required an all-in-one transport refrigeration solution to maintain an unbroken cold chain during multiple trips a day from their dark stores to the customers’ doorstep. Protecting the cargo at all times, even when the van’s ignition is switched off, was one of the main requisites met by the E-200.

The E-200, unlike typical direct drive solutions designed for diesel combustion engines, delivers constant capacity independently from the vehicles’ RPM. The E-200 units’ hold-over capacity is enabled by the van’s auxiliary battery, allowing also for active Start/Stop functionality to save fuel, lower noise and vehicle emissions.

The hold-over feature keeps the refrigeration unit operating without any emissions while the driver stops for delivery, has a break or needs to turn off the vehicle for longer. This gives the driver the flexibility to stop without the need to keep the vehicle running on idle to keep the transported goods cooled.

“The technology of the E-200 gives our customers a unique mix of control, convenience, utilization, and reliability that help them improve their transport operations,” said Steve Williams, area sales manager at Thermo King. “The E-200 represents the next generation of our fully electric refrigeration units and has been generating very positive feedback from our customers. They benefit from efficient temperature management, zero-emission, low noise and can move foods and goods with maximum convenience for the people in urban areas.”

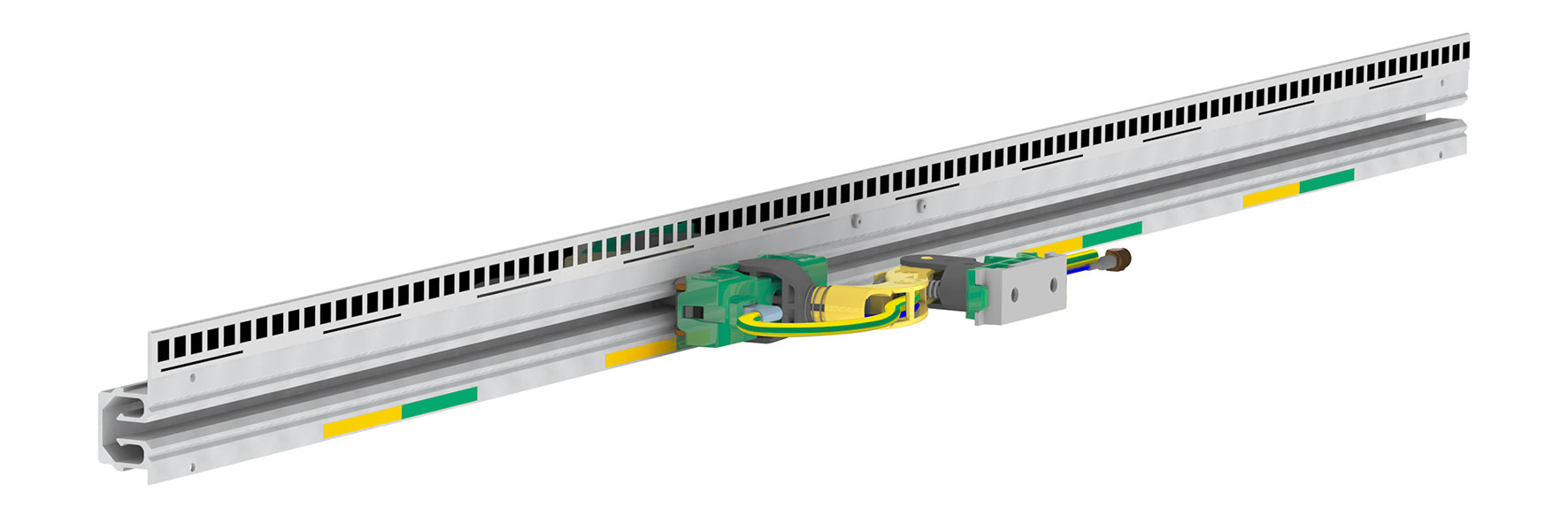

Being inverter driven, unlike typical direct drive solutions designed for diesel combustion engines, the E-200 delivers constant capacity independently from the vehicles’ engine, and can work with both electric and engine-powered vehicles. The E-200 Plug-and-play solution requiring no drive kit nor road compressor and no vehicle modifications to function. It features patented power management, which contributes to lower energy consumption, increased vehicle autonomy and higher efficiency and reliability.

By varying the electricity flowing to the refrigeration unit, the inverter can provide more power when needed resulting in a faster temperature pull down during pre-cooling. By carefully controlling the power supply, the inverter provides accurate control of the motor speed and the exact cooling or heating capacity needed to control the temperature.

Being fully-electric, the E-200 allows the vehicles to comply with PIEK standards and Urban Vehicle Access Regulations (UVARs) for sound levels in urban environments, and enables them to enter low emission zones, and run quiet to complete night-time deliveries.

The E-200 product development is aligned with Trane Technologies 2030 sustainability aspirations, and the commitment to, through the heating, ventilation, air-conditioning (HVAC) and transport refrigeration products and services, reduce customer carbon footprint by one gigaton1 CO2e – equivalent to the annual emissions of Italy, France and the United Kingdom combined.