Geek+, a global leading AMR provider, and Bosch Rexroth, one of the world’s leading supplier of drive and control technologies, has announced a technology partnership to develop and leverage the latest technologies for autonomous mobile robots (AMR) that will bring enhanced smart logistics solutions to customers around the world.

Geek+&Bosch Rexroth Thomas Fechner (SVP Product Area New Business at Bosch Rexroth) and Jackson Zhang (VP Europe Geek+)

Geek+& Bosch Rexroth Joerg Heckel (PD Intralogistics Robotics at Bosch Rexroth), Thomas Fechner (SVP Product Area New Business at Bosch Rexroth) and Jackson Zhang (VP Europe Geek+)(PD Intralogistics Robotics at Bosch Rexroth), Thomas Fechner (SVP Product Area New Business at Bosch Rexroth) and Jackson Zhang (VP Europe Geek+)

As part of this partnership, both parties will collaborate on advanced mobile robotics technologies and software development to enhance AMR intelligence and performance, empowering customers worldwide.

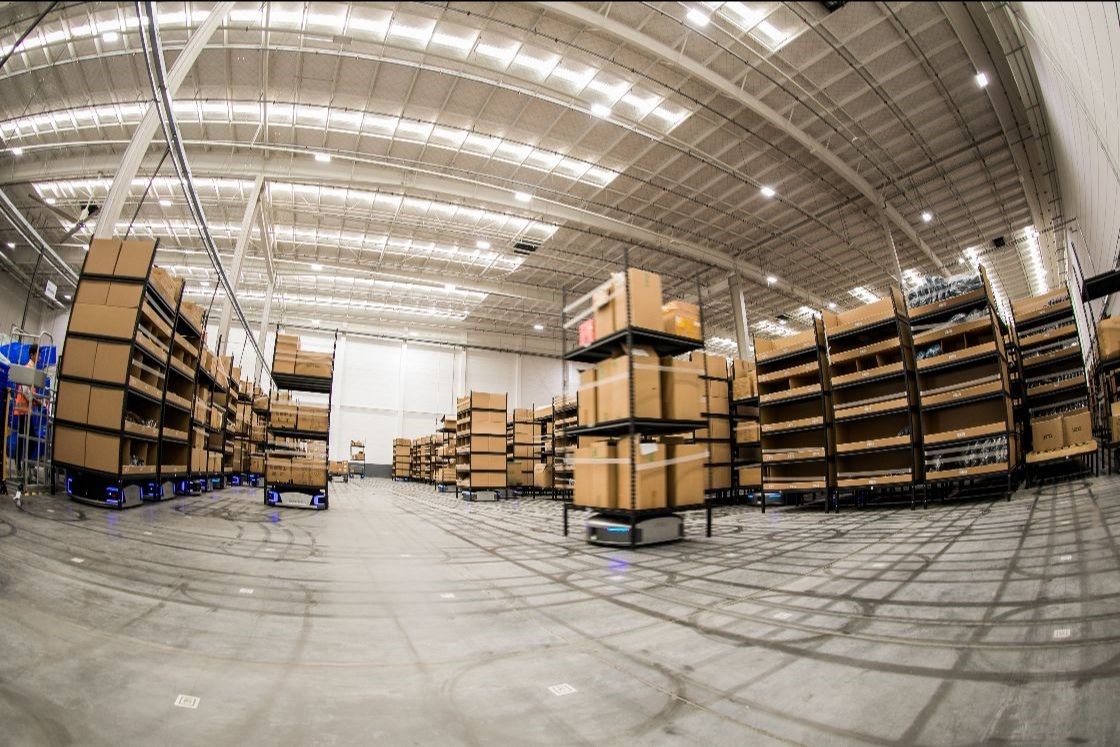

As a pioneer in AMR and smart logistics, Geek+ has seen rapid business growth and accelerated expansion into new geographies. According to Interact Analysis, a leading international market research consultancy in automation, Geek+ is the global No.1 in the AMR sector with a 10% market share. The company delivers best-in-class robotics solutions to some of the world’s leading brands across industries including Nike, Decathlon, Walmart, and Dell, among others.

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. Its Intralogistics Robotics project provides modular software and hardware components for a wide range of AGV manufacturers. For innovative software-solutions, the company combines maximum flexibility at start-up level with intensive research and profound application knowledge in the field of autonomous driving within the Bosch Group.

The partnership will bring together the expertise of the two industry leaders in their respective domains to create value-added solutions for Geek+ customers to improve their own logistics operations.

“For instance, the Locator, a localization software for the reliable positioning and orientation of mobile robots, offers maximum flexibility and an outstanding usability,” said Jörg Heckel, project director Intralogistics Robotics at Bosch Rexroth. “Geek+ has presented a flexible, professional and collaborative mindset to meet the fast growing demands of automation projects. We are looking forward to shape a dynamic robotics market together.”