Freight exchange Teleroute, which is part of the Alpega Group, has launched two major improvements to its current offering: an advanced API interface and a new version of its mobile application. Both are focused on closing a transport deal and finding new business partners more efficiently.

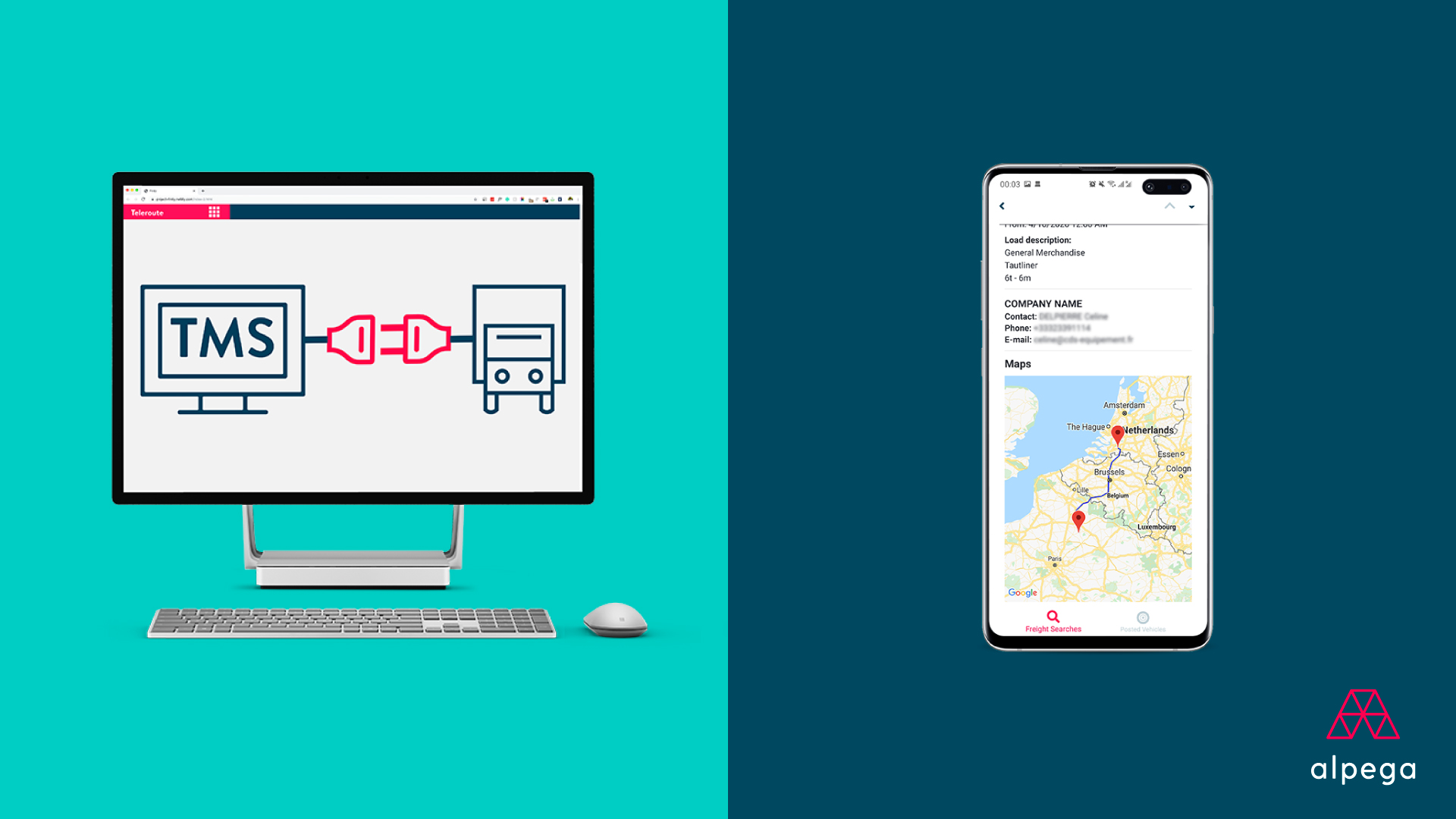

Teleroute’s new API interface allows companies to save a significant amount of time and avoid errors by posting their loads in the freight exchange directly from their TMS (Transport Management System). At the same time, companies can find new qualified partners via the interface, in order to increase business opportunities and create a stable network of collaborators to optimize all transport operations. The new API interface is integrated with more than 50 TMS solutions and has no extra cost to Teleroute’s customers.

It is no surprise that more and more transport companies are struggling to find freight and have to run empty. In order to help their clients in this situation, Teleroute improved its mobile app and now users are able to perform multiple freight searches simultaneously, to contact the offering company in one click and offer truck capacity. Additionally, this new mobile app provides the possibility of accessing the large amount of freights and trucks offered in Wtransnet, leading freight exchange in Iberia and also part of Alpega Group.

Both actions respond to the commitment of Teleroute to continue investing in technology that really helps the transport sector, on which Fabrice Douteaud, Alpega Group marketplace COO, affirms:

“Our mission is to provide the transport sector smart tools to facilitate the collaboration and help our clients in their day to day challenges. With this goal in mind, we are working hard every day to improve the benefits we offer through our platform in order to provide greater added value.”