The leading wholesaler in the Swiss organic market, Bio Partner, has doubled its output following the implementation of innovative robotic logistics from Swisslog at its facility in Aargau, Switzerland.

Bio Partner supplies business customers in the organic specialist trade as well as the rest of the retail and food industry from its location in Seon. As a result of the merger with Somona GmbH, the warehouse reached its performance and capacity limits, and the wholesaler turned to a local partner with a global footprint to deliver an automated storage system.

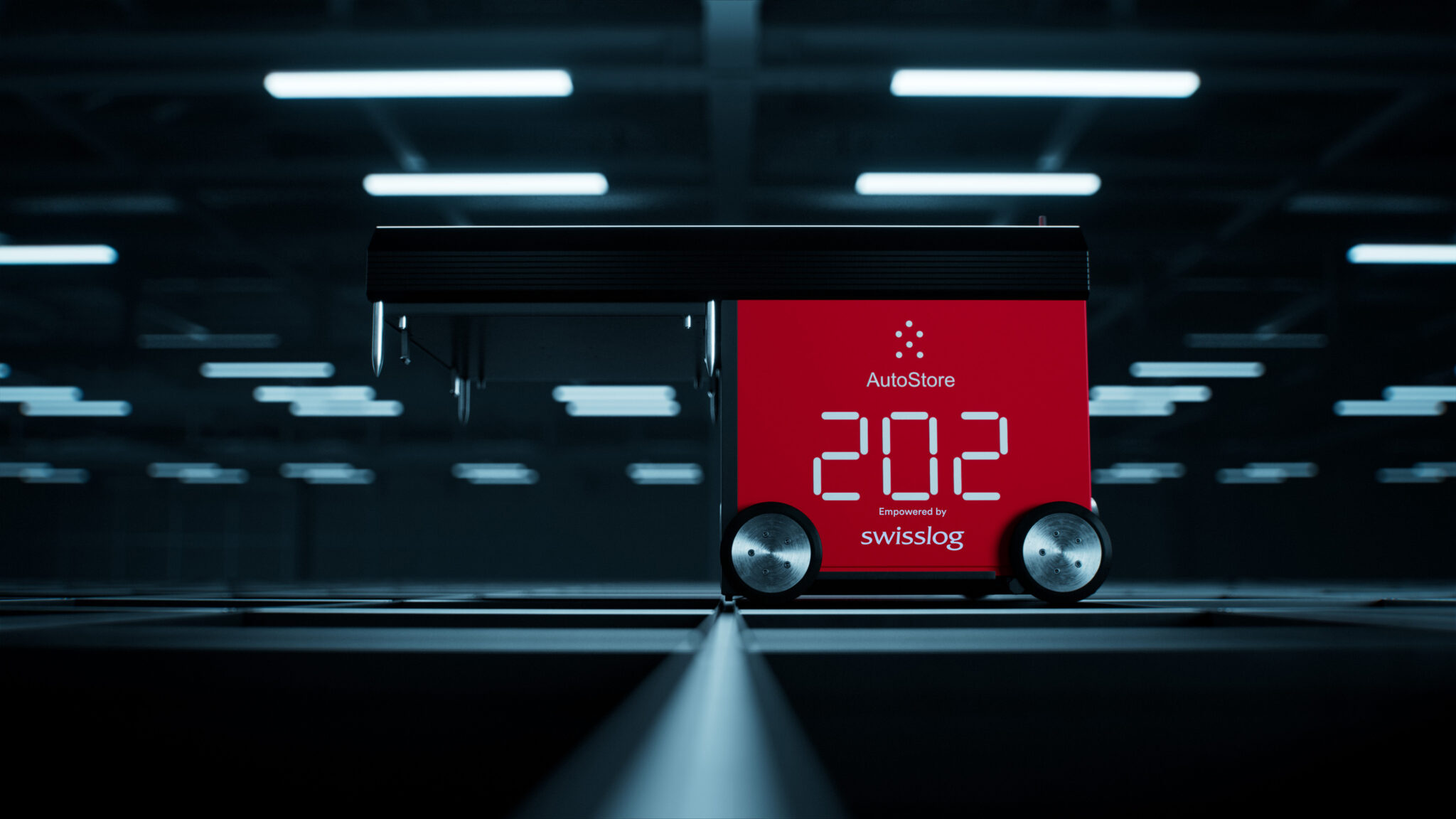

The 12,200m2 warehouse handles 10,000+ products, a process now optimized thanks to the high-performance AutoStore storage solution, delivered by global warehouse automation specialist, Swisslog, a member of the KUKA group.

“Companies with large warehouses have to constantly work on increasing efficiency and our robot systems work flawlessly around the clock,” says Swisslog CEO, Dr. Christian Baur. The aim of this new system from Swisslog is to automate the storage and picking of the dry assortment and to compress it in terms of volume.

Consistently high performance

The new AutoStore system at Bio Partner has 44 robots with the ability to handle 25,000 containers and at least 6,000 products completely autonomously. “The high-tech robots create a volume of 900 containers per hour and, depending on the development, this system can still be expanded considerably,” says CEO, Dr. Baur.

The orders are automatically transmitted to the AutoStore system and processed in accordance with parallel processes, which is a huge advantage in large warehouses. This means that higher volumes can be made available in a shorter time. Picking errors cost time and money, and robots don’t make mistakes since the hardware and software work together perfectly. Bio Partner relies on the modular warehouse management software SynQ from Swisslog to orchestrate the warehouse and picking processes based on data-based insights.

“Our company relies on long-term, sustainable partnerships. With Swisslog, we found a strong local partner and the system installation was quick and easy,” commented Lukas Mettler, head of warehouse logistics at Bio Partner.

As a leading global integrator with over 200 realized projects, this is just one example of many projects which showcase the wide implementation spectrum of AutoStore empowered by Swisslog.