Constraints to business expansion, presented by manual packing, lead one international logistics business to invest in fast, fit-to-size automated packaging technology. Established in 2015, Global Freight Management Hersden Ltd is a highly successful international logistics business. Having at the outset secured the Warehousing and Logistics Contract for iconic toy and hobbies brand, Hornby Hobbies, the business has gone on to win a steady stream of clients across the mobile phone, sports equipment and organic food sectors.

From a 120,000 sq ft warehouse in Hersden, Kent, the global logistics services company picks, packs and despatches orders to both trade customers and direct to consumers, across the world. However in 2020, with the explosive growth of ecommerce, the management team quickly came to realise that their highly manual packing operation was a constraint on further expansion of the business.

“We were limited by the fact that there were only so many people that you could get to work in a given space, for so many hours, to pack product,” says, Will Todd, Director and part owner of Global Freight Management Hersden. “We realised that we needed to introduce a level of automation to our packing processes if we were to gain the additional capacity required to take on new clients and develop the business.”

But, for their largest client, Hornby Hobbies, the integrity and quality of the outer packaging was of critical importance, as many of their highly sought after toys and models are purchased by enthusiasts and discerning collectors that seek to retain the original product packaging in mint condition for twenty years or more. A crumpled corner or a scratch to the varnish can be a big issue.

Important considerations for the business were: Could automation deliver the precision and care needed to ensure full protection of the product? And would automation deliver the speed, throughput and productivity levels required to future proof the business?

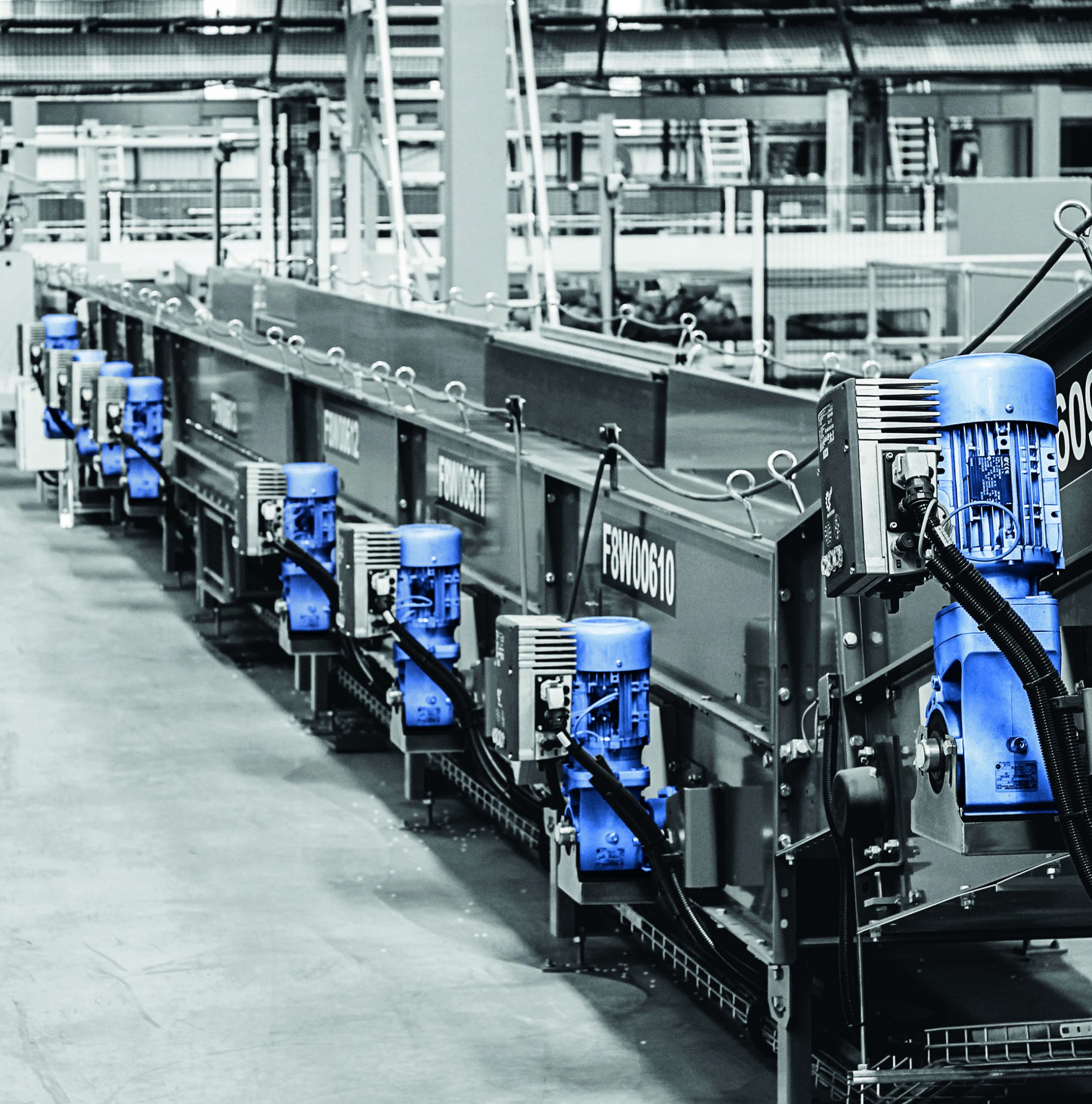

The solution came in the form of Quadient’s CVP Impack; an advanced automated fit-to-size packaging system, capable of tailor making 500 individual cardboard packages per hour. Will Todd explains: “I read about the CVP Impack in the trade press. It sounded impressive, so I went to see one in operation and realised it was the way to go.”

At the end of July 2020 Quadient’s engineers delivered and installed a CVP Impack automated packaging system, complete with a twin feed for both 600 and 1000 mm cardboard to minimise off-cut waste – the first application of a twin feed CVP Impack in the UK. Will Todd says, “Quadient gave us a delivery date earlier than we were expecting. The machine was unloaded and installed, and within a day perfect boxes were being produced.”

Quadient’s CVP Impack is unique in that it has the potential to construct bespoke individual cardboard boxes to the exact size of an ordered item at the rate of up to of 500 boxes per hour – combining multiple items, as required.

The CVP Impack measures, constructs, tapes, weighs and labels each parcel in one seamless process. The operator simply places the item(s) to be packed onto the machine and scans the order. The system identifies the order and automatically conveys the items to a 3D scanner to measure and calculate the minimum box size required. The cardboard is then cut and folded to create a snug fit around the goods and tape is applied on just two sides to secure the box. Then an in-line scale checks the weight against the order and, finally, the box is automatically conveyed to a label printer where a carrier compliant label is created and applied. The whole process, from start to finish, takes just thirty seconds with a custom made box configured every seven seconds.

“It’s a fabulous piece of kit. It does exactly what was promised. It packs products in the most economically, environmentally friendly and protective way – at high speeds. The packages are perfect for shipping around the world,” says Will Todd.

He points out that although their key reason for investing in the CVP Impack was extra packaging capacity to expand the business, there were several other important benefits too.

“As we are shipping out every order as a box made precisely to the optimum size for the order, we are now using less cardboard – probably around 30% less – which is good from both an environmental and cost view point,” says Will Todd. “And as the boxes are right-sized, that means fewer pallets of boxes being shipped, less lorries on the road and lower emissions – which again brings cost savings.”

The CVP Impack has also freed up labour resources for other tasks, giving greater flexibility across warehouse processes – all part of the business expansion plan.

Will Todd is enthusiastic about the machine’s capabilities and the potential it offers the business. “It’s performing brilliantly. You can’t get much faster in terms of packaging performance and that gives us the capacity to take on more clients.”

More on Quadient’s fit-to-size automated packaging solutions at https://packagingbyquadient.com