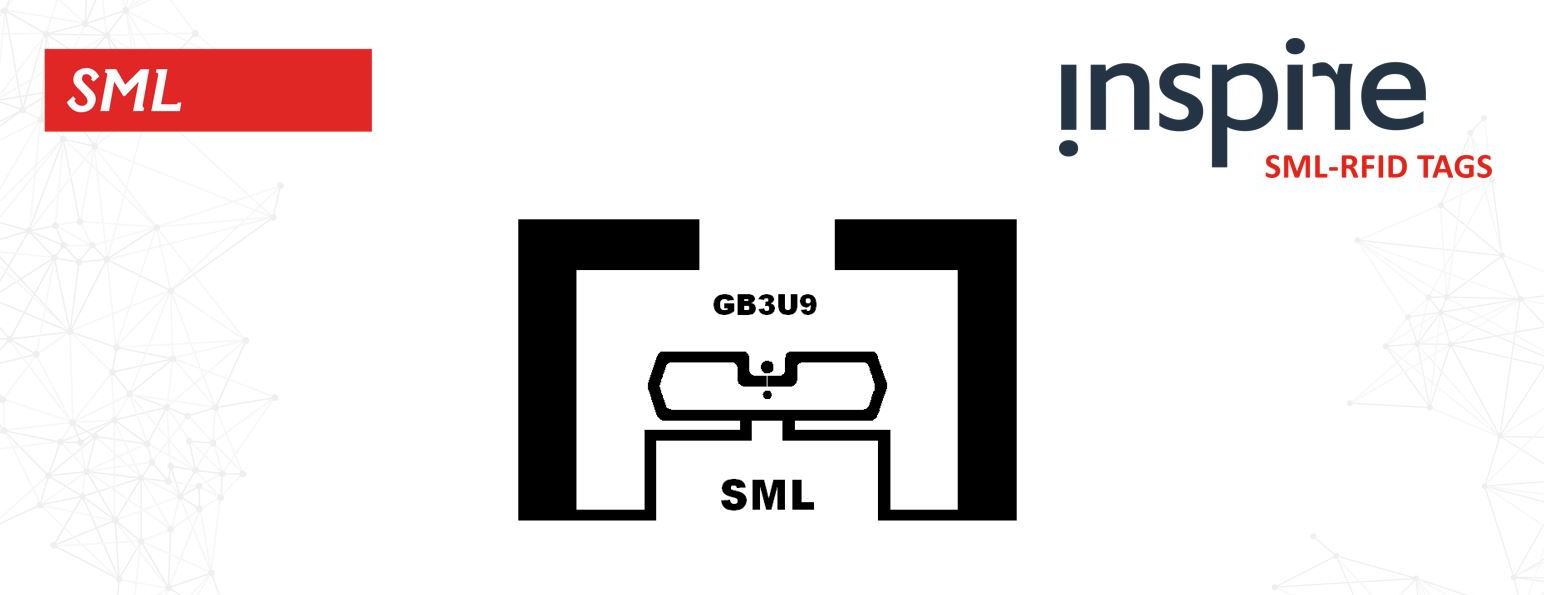

SML RFID has today announced the latest addition to its range of high-performance RFID inlays, one of the market’s first UCode9 ARC certified inlay – GB3U9. Designed to support retailers with a wide spectrum of inventory management and customer experience use cases, the GB3U9 is equipped with the latest RFID chip from NXP, UCODE 9, enabling industry best read sensitivity, resulting in high quality and rapid inventory counting in dense RFID tag populations.

Available immediately, the SML GB3U9 provides a high-quality RF performance improvement for any given sector. The GB3 inlay offers a unique solution for the retail apparel, footwear, cosmetics, and electronic industries. Featuring a 3D orientation design, the inlay can be used for item management across various materials, including denim, poly bags, apparel tags, and boxed items, and its broadband design offers outstanding performance across worldwide regulations to support retailers as they manage items along the supply chain from source to store.

The inlay, like any of the SML inlays, can be converted into an adhesive label, integrated price ticket or a sew-in tag form factor to support every merchandizing strategy. SML has a family of U9 based inlays that will also be certified in the next few months, establishing the benchmark in inlay performance for the retail industry.

The GB3U9 inlay meets a number of ARC categories, including Spec N, Spec Q, Spec M, Spec G, Spec F, Spec L, Spec W1, Spec W2, Spec W3, Spec W4, Spec W5, Spec W6, Spec I, and Spec K. Set by Auburn University, the ARC categories are a set of industry-wide performance requirements needed to ensure that the RFID technology meets or exceeds a performance level that benefits both retailers and suppliers.

Dean Frew, Chief Technology Officer and Senior Vice President of RFID solutions at SML Group, said: “As adoption of Item-Level RFID in retailers of all types continues to see dramatic growth, technology innovation like this tag is one of the elements fuelling that adoption. Our tests in retail store environments show that our U9 family of tags can reduce handheld stock count time while achieving >98% inventory accuracy, greatly enhancing in-store and BOPIS inventory availability. The tag will also improve accuracy in numerous retailers’ supply chain scenarios such as reading high density packed cases of product in-tunnels and dock door use cases.”

Dr. Jeremy Liu, Vice President of RFID Technology, SML Group, commented: “SML global innovation centres fully brought out the capabilities of UCODE 9 chip. The advanced antenna design of GB3U9 showed a great balance between forward and reversed sensitivity. It enables the inlay to provide an exceptional solution to the modern retailer’s inventory management requirements. The compact antenna design, along with global frequency operation and omni-directional radiation capabilities, has created a versatile inlay that perfectly caters to the demands of today’s supply chain and in-store operations.”