The Covid-19 pandemic and the 2021 COP26 summit have sped up sustainability awareness around the world, increasing pressure on companies to make meaningful changes to operations, writes Christos Chamberlain, Flexport’s UK General Manager.

The pandemic has impacted multiple industries, and some such as e-commerce companies saw significant benefits as online shopping spending grew. However, much of this convenience has had consequences, with public scrutiny turning on some in the industry carrying out unsustainable practices.

Following COP26, 90% of world GDP is now covered by net-zero commitments for 2030, and according to Forbes, “sustainable, resilient operations” are the number one business trend for 2022. Companies can build a competitive advantage in their sector by acknowledging trends and embedding sustainability into the core of their business model. Avoiding greenwashing campaigns is vital though, and organisations must take real action to reduce carbon emissions by cutting business operation output and supply chain waste.

Sustainable supply chains

The supply chain has come into sharper focus for most brands since the start of the pandemic, driven by an environment of disruption and surging costs because of lockdowns and surges in demand around the world. With this has come to a greater demand for visibility into the supply chain and more strategic questions being asked than pre-pandemic.

Furthermore, companies are also thinking about their supply chains differently, looking for more reliability, flexibility, and sustainability versus the traditional push for greater efficiency.

A clear trend we are seeing, particularly in the fashion retail industry, is the heightened level of scrutiny into the supply chain, from alternative sourcing regions to different modes of transport, often in response to ‘fast-fashion’ trends. With that has come a more informed and holistic understanding of the environmental impact of accessing goods.

What is encouraging, is that as sustainability becomes more mainstream, unsustainable supply chain practices will start to cost as investors prioritise companies embracing sustainability.

Addressing unsustainable retail supply chains

The spotlight is now on businesses, with consumers expecting them to address issues around sustainability and ethics – particularly in younger generations. A report by Avery Dennison which surveyed more than 5,000 fashion buyers from across the U.S., UK, France, Germany and China revealed that 60% of fashion shoppers want more transparency about the production journey of the clothes they are buying in order to make more informed and ethical decisions.

What this tells us is that if brands acknowledge and address consumer attitudes around sustainability, they are more likely to attract new customers and drive sustainable brand loyalty.

Progress is clearly being made – and we’ve seen a significant uptick in organisations considering their impact on the environment. Since the second half of 2021, we’ve seen a 40% increase in clients involved in our social and environmental sustainability programs in Europe, using tools such as our Carbon Offset Program – with carbon offsets doubling between 2020 and 2021.

Track and Trace

The first step to improving carbon credentials is capturing accurate data to provide greater visibility and then effectively measuring that information to prioritise resources. A clear and standardised baseline of measurement is essential. When it comes to carbon emissions, different methodologies can be employed, and it can be difficult to know where to start. The way to tackle this problem is to use accredited methodologies based on the standards that are industry wide, regulated, and undergo a regular cadence of review and update.

Sustainable Supply Chains

With visibility of where the most carbon is being generated, organisations can focus on finding solutions. For example, air purifying specialist Rensair has talked about switching its focus from air to ocean freight, motivated by the opportunity to lower its carbon footprint.

CEO and co-founder Christian Hendriksen commented at the time: “Our business is built on providing clean air for everyone, so we have a wider focus on ensuring we are contributing as much as we can to solving the global climate crisis.”

The company has, like many others, pledged to become carbon neutral: “Being able to ship our goods via ocean while offsetting carbon at the same time is a key benefit for us.”

Purpose doesn’t only drive brand identity, it drives growth, generates new commodities, and presents opportunities in untapped markets – which leads to sustainable business success. By acknowledging consumer attitudes and behaviour towards sustainable issues, and clearly taking action to address them, companies across any industry can leverage consumer support and drive sustained brand loyalty.

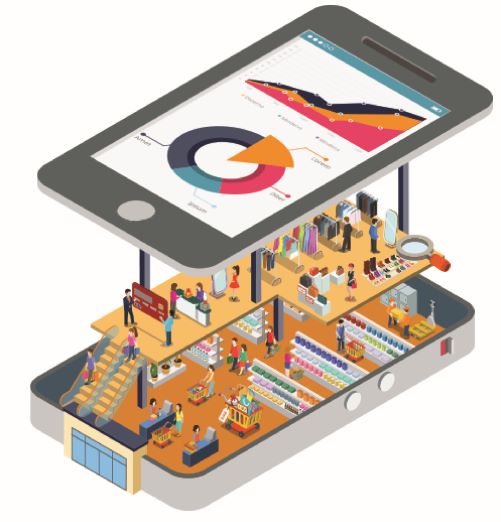

Having the visibility and accessibility to all stages in the supply chain process can particularly benefit e-commerce and retail companies by not only saving costs and optimising efficiency, but it also helps reduce unnecessary waste and carbon emissions, which helps save our environment.

similar news