The pharmaceutical retail, wholesale and distribution sector is ‘in play’, as they say on the markets, writes Leigh Anderson (pictured), Managing Director at Bis Henderson Recruitment. The group around Lloyds Pharmacy (retail) and AAH Pharmaceuticals (wholesale) has been acquired by Aurelius; Walden has bought Movianto, joining Eurotranspharma and Ciblex and so bolstering its claim to be ‘the European leader in transport and logistics for pharma’; and takeover rumours swirl around Walgreen-owned Boots/Alliance, along with other companies in the UK and Europe.

In parallel with this market activity, we are seeing a marked upswing in recruitment for senior and middle-ranking logistics and supply chain posts in the sector. And it’s hardly surprising, as wider skill sets from pertinent related sectors will be needed.

Changes in ownership invariably trigger reviews of business strategies and consequent reassessment of whether the right skills and expertise are in place to achieve the new goals. But this comes on top of more fundamental changes that have been triggered or accelerated by the Covid pandemic.

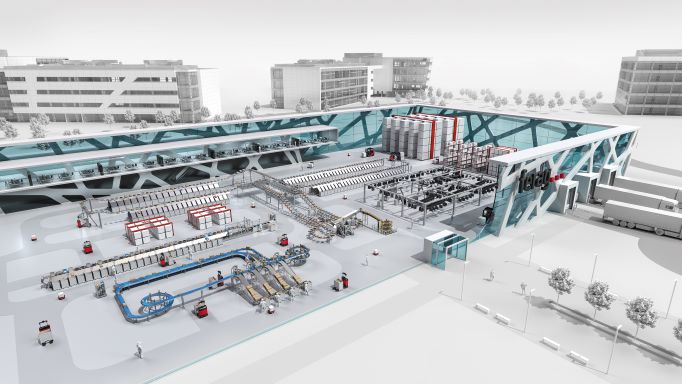

Restructuring, and pharmacy involvement in vaccine rollouts, has prompted significant and ongoing investment in new distribution centres, final mile delivery and automation – including robotic dispensing solutions. In addition, the pandemic has revealed critical dependencies, especially for packaging and drug delivery supplies, which has pushed supply chain resilience higher up on corporate agendas.

More fundamentally, the pandemic has accelerated the digitalisation of medicine, including pharmacology. Pressure on general practice has been met by ramping up the NHS Direct platform, and by a boom in private sector on-line medicine, through firms such as Babylon, PushDoctor and Lloyds Pharmacy Clinical Homecare. And this is extending to the on-line ordering of drugs and therapies, particularly repeat prescriptions, for delivery Direct-to-Patient.

The processes are analogous to, but with significant differences from, consumer eCommerce. Direct-to-Patient promises to be more convenient, to reduce waste, to encourage better course adherence by patients, as well as helping to control the problem of parallel imports. Better visibility of demand can be fed into predictive analytics for further improvement. But exactly what this might mean for the role of wholesalers is still in question.

The vaccine development and roll-out process has also highlighted the importance of accurate logistics to clinical trials, where any supply failure risks negating months or years of development work and delaying the deployment of valuable therapies.

Healthcare is a data-rich environment and there is now a real emphasis on using sophisticated data analytics, to quote Walden, “to optimise logistics processes and streamline flows both within health entities (pharmacies, hospitals), and also directly to patients”. Digitalisation is rapidly being applied to a host of regulatory requirements, from real-time traceability to quality control, market authorisation, pharmaceutical release, Customs brokerage, and more.

Forward-looking companies are also beginning to plan for an era of individually tailored therapies, especially around cell and gene therapies. So-called ‘vein to vein’ supply chains will require needle-sharp logistics to move blood or tissue samples from the patient to the laboratory as well as delivering the resultant therapy back to the patient – all under critical time pressure. The trend, already evident, is forever wider product ranges, in smaller volumes and with high demand volatility, with very short shelf lives, requiring differing temperature regimes, dealt with in part by increasing use of postponement strategies. And, needless to say, all this has to be conducted with the highest ethical and customer-centric focus.

So what are the skills companies are looking for to meet this complex agenda? Clearly, experience of significant change management will be valuable. There are specific technical skills in demand also – in robotics and automation, in the application of big data analytics to supply chain and distribution activities, and in building effective direct to user distribution channels taking appropriate learnings from consumer eCommerce. Experience in time-critical sectors (short life products and stringent delivery time requirements), and in reducing fulfilment times is in demand, as is experience in using procurement and supplier relations processes to improve supply chain resilience.

Managers at all levels will also need an understanding of how heavily regulated industries have to operate – especially as some innovations in, for example, Direct-to-Patient supply may, in some countries, require legal or regulatory change.

Partly because of this, there has been an unspoken assumption in parts of the sector that senior staff really need a medical, pharmacological or life science background. But it is now appreciated that this isn’t necessarily the case, and that there are lessons to be learned and knowledge to be transferred from other sectors – consumer eCommerce, temperature-controlled food distribution chains, even the data analytics used in high volume, but high variance, industries such as fashion.

Bis Henderson has extensive experience of helping managers with these high value skills transition into different industrial and commercial sectors, enhancing their careers and facilitating knowledge transfer to new employers. As a natural port of call for logistics and supply chain professionals seeking to develop, we have access to a deep pool of the skills and talent that the pharmaceutical distribution sector will need to meet the coming challenges.