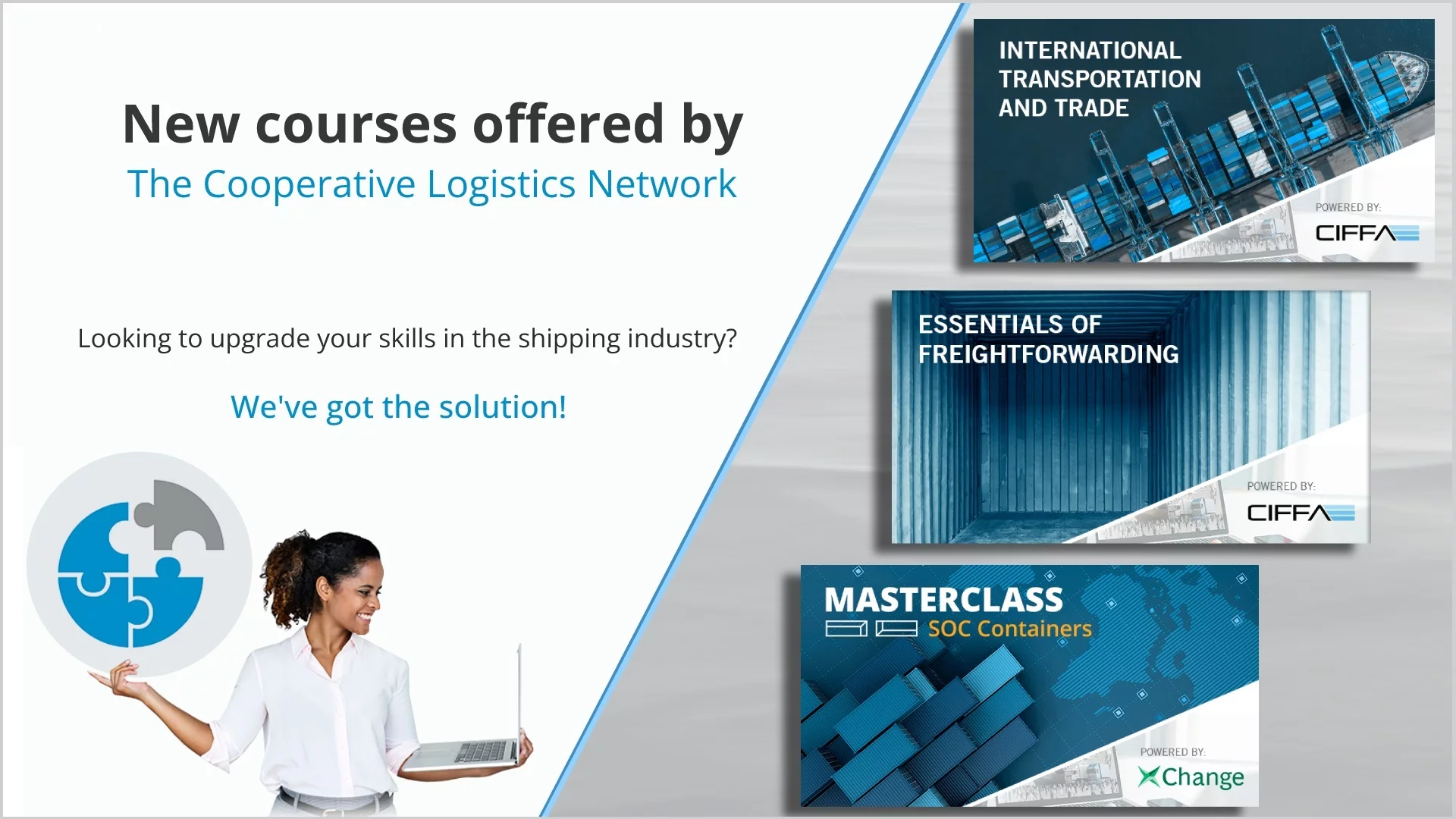

The Cooperative Logistics Network – an international alliance of more than 320 hand-picked freight forwarders – has launched its Online Logistics Academy. To this end, the E-Learning Platform has been inaugurated with two courses specialised in international logistics and freight forwarding and a SOC Masterclass focused on Shipper Owned Containers.

The programmes will allow members to learn and execute complicated supply chain processes, enhance their knowledge of logistics tools, and prepare themselves to effectively deal with the present challenges in the industry.

In order to offer the best quality education, The Cooperative has established a partnership with The Canadian International Freight Forwarders Association- an organisation with over six decades of experience in education. Additionally, The Coop has also cooperated with Container xChange – a neutral platform connecting hundreds of logistics companies – that provides a broad range of online educational course materials to help freight forwarders get a better knowledge of container leasing.

“The future of the freight forwarding sector is constantly evolving. In this age of digitisation, it is crucial for small and mid-sized logistics companies to work towards upskilling and expanding their knowledge base. By offering these specially formulated courses, The Cooperative gives its members an additional service for them to be more competitive, enhance their productivity and boost their earning potential,” states Antonio Torres, President and Founder of The Cooperative Logistics Network.

The courses are both meant for professionals working in the field of transportation and logistics who want to broaden their industry knowledge and sharpen their skills and newcomers who want the perfect start to their journey in this industry.

The Cooperative agents will get to attend two levels of freight forwarding courses provided by CIFFA and designed by the Schulich Executive Education Centre (SEEC). The first course, International Transportation and Trade, is meant for those agents who want to master the foundations of global freight forwarding, risk management, quotations, and freight costs. The second course, Essentials of Freight Forwarding, will train members on basic topics such as packaging, documentation, cargo insurance or cargo security.

These training programmes can be completed at the students’ suitable pace. within three months CIFFA will provide with interactive classes, audio, video lessons, and a downloadable e-book.

In addition to these courses, The Cooperative Logistics Network offers the SOC Container Masterclass offered by xChange which is an all-inclusive training regarding the handling of Shipper Owned Containers. The Cooperative members who register for one of the above-mentioned logistics courses by CIFFA will get free access to this Masterclass.