On June 20, Linde Material Handling literally laid out the red carpet for its customers and other interested parties for nine event days. On an area of 17,000 square meters at the Mannheim Maimarkt site, the intralogistics specialist is presenting its extensive portfolio of products, solutions and services – for example, using the case of a bottle manufacturer to demonstrate the process from goods receipt to the last mile in the store. In addition, the vast expertise of the company’s product experts and consultants is available to visitors. Several thousand guests are expected at the World of Material Handling (WoMH), mainly from Europe.

“Over the past two years, the overall economic environment has changed noticeably, and with it the demands on in-house material flow,” said Stefan Prokosch, Senior Vice President Brand Management Linde Material Handling, at the start of the event. “Increased energy costs, a shortage of skilled workers, higher demands on operational safety and the search for solutions that ensure greater sustainability – these are just some of the challenges facing our customers. At the same time, it’s important to tap the optimization potential offered by digitization and networking.” According to the chief brand manager, customer requirements can no longer be met with forklifts and warehouse technology equipment alone. “Over the last few years, Linde Material Handling has developed into a very broad-based solution provider that, in addition to its growing product range, offers an ever-increasing number of software solutions, assistance systems, consulting tools and service offerings such as battery leasing or predictive maintenance,” Prokosch explained. “In doing so, we are always close to our customers – in line with the WoMH 2022 motto: YOUR WAY IS OUR WAY.”

The WoMH is an event that is second to none in the material handling industry. The idea behind this customer event is that guests do not just come to the exhibitors’ stands for a brief flying visit, as is usual at trade shows. Instead, they can experience the products and solutions live and in motion for an entire day in realistic application scenarios. At the same time, they have the opportunity to discuss their individual challenges and wishes with product experts and consultants and find suitable solutions. The international event created by Linde MH for this purpose sets an example in this regard.

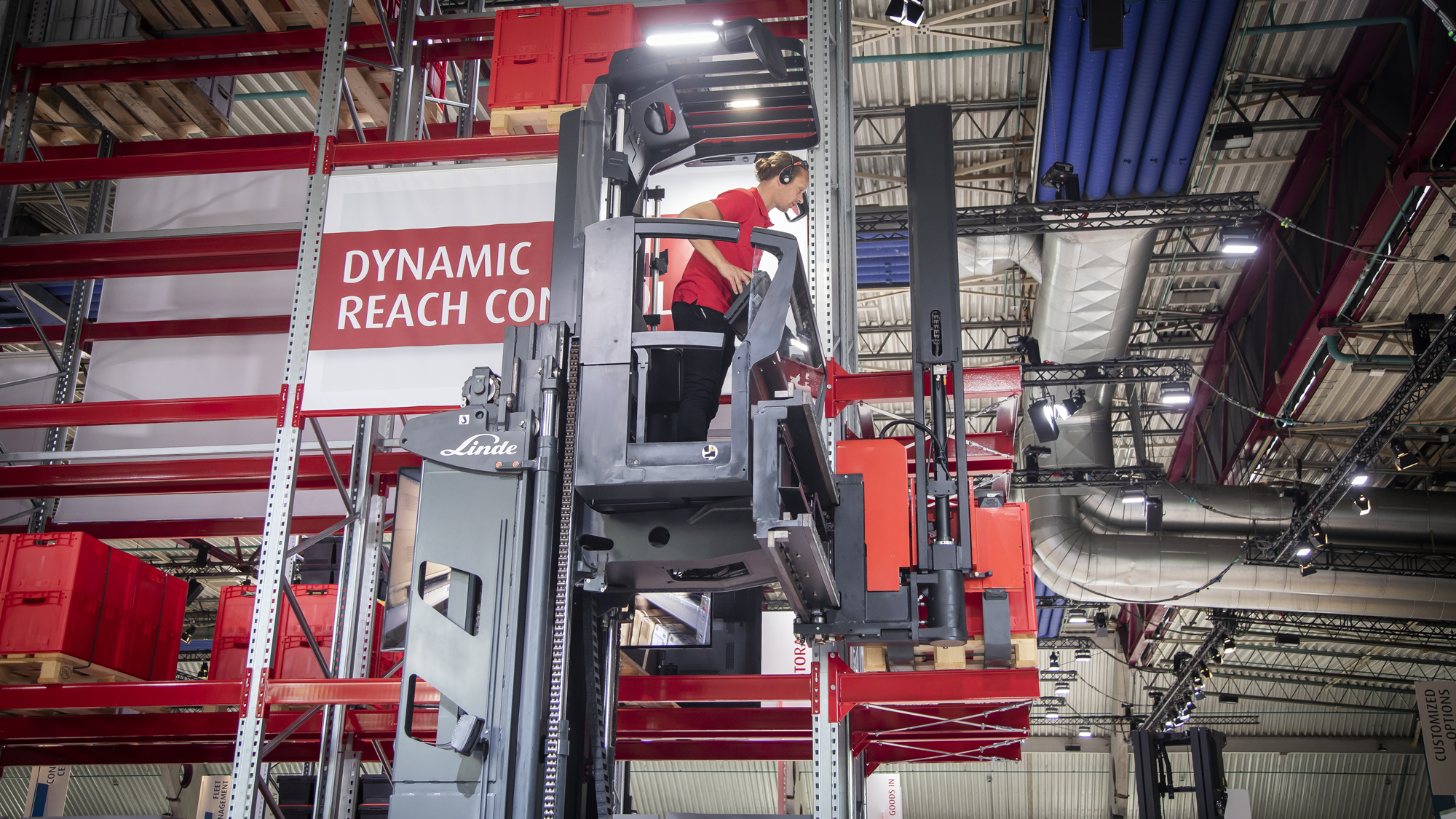

In the large exhibition hall on the Maimarkt site, a complete flow of goods for the production of glass bottles was recreated. From goods receipt to storage, picking, production and last mile delivery, the demonstration shows how the transport and handling of loads can be solved efficiently and safely in an ergonomic and sustainable manner. In the “control center”, visitors can explicitly see the benefits that can be achieved through the digitalization and networking of warehouse processes. Other themed areas show the extensive portfolio of safety solutions, the various available energy concepts, the fleet management solution “connect” and possibilities for automation. What’s more, guests are able to do more than just see and touch the over 100 vehicles on display: In a large outdoor area, a multitude of vehicles is waiting to completely convince operators of their worth during a test drive.

The products and solutions of the numerous partner companies are integrated in the exhibition at various appropriate locations. For example, the safety guard rails from A-Safe can be found in the “Goods Receipt” area, a heavy-duty rack from Bito and the automatic small parts warehouse “AutoStore” from Dematic are on display in the “Warehouse” section, a mobile weighing device from Ravas is located in the “Order Picking” area, and a lifting platform from Palfinger can be found in the “Last Mile” area. Additional partner booths are located in various other areas, grouped together according to product type. EnerSys, Fronius, Hoppecke and Plug Power are expanding the “Energy” area, while Dematic is found in the “Intralogistics” area, showing how automatic solutions can be combined with manual and automated industrial trucks.