Conker, which provides rugged, wearable and scannable devices for mobile workforces, is expanding yet again with the appointment of five new staff members and a head of team promotion.

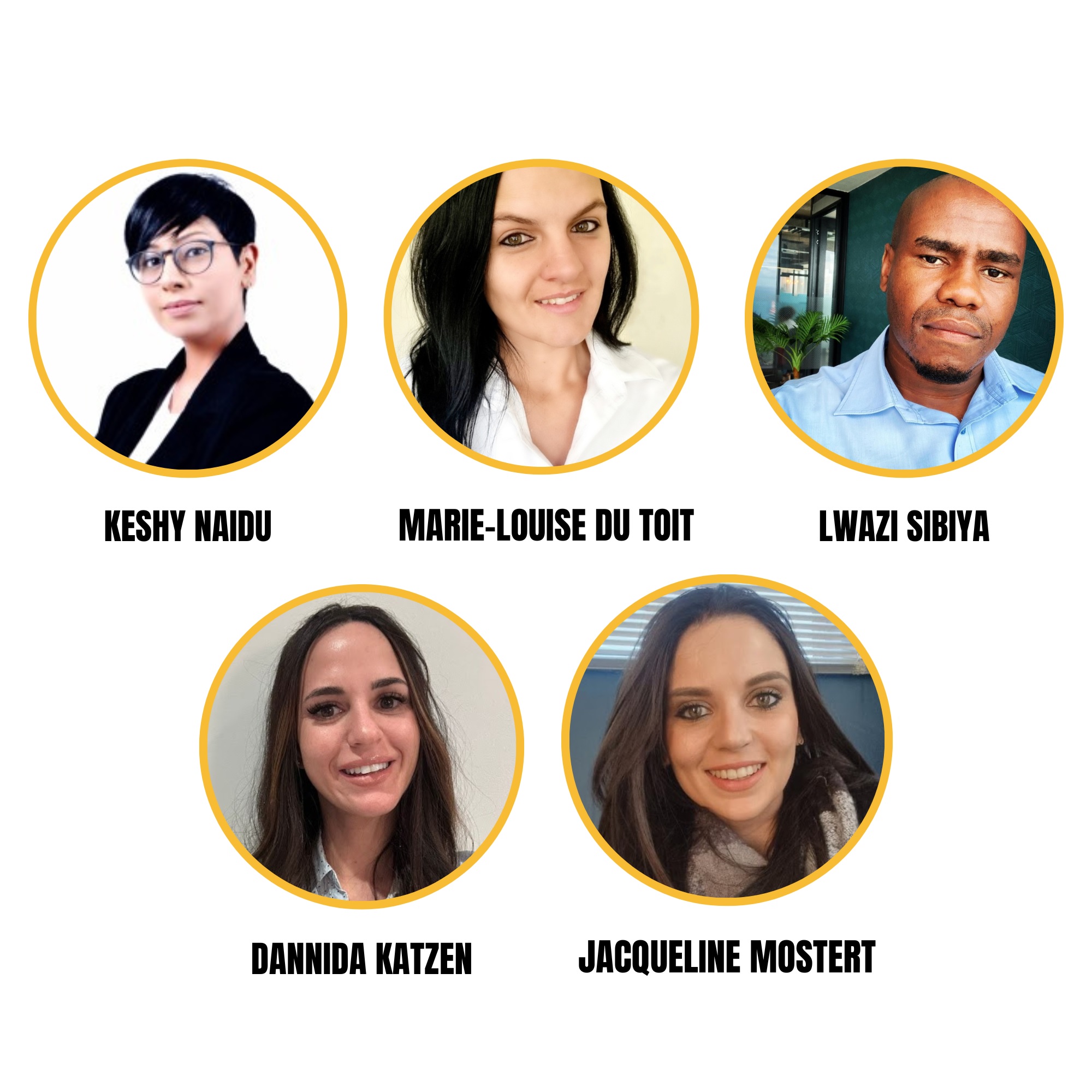

Lwazi Sibiya joins Conker in the role of business development executive. With a strong consultative approach and a firm belief in the importance of customer-centricity in service-driven sectors, Sibiya comments: “I am delighted to join Conker with its reputation for outstanding customer service.”

Keshny Naidu has over 20 years’ experience in client relationship management and has been appointed business development executive for the retail and wholesale sectors. She comments: “Joining Conker is a great opportunity to add value to this forward-thinking device specialist. I am looking forward to a new challenge and working closely with retail and wholesale businesses to understand the demands of their environment.”

Dannida Katzen will also be coming on board as business development executive. Outlining her approach to the role, Katzen says: “I am dedicated to bringing successful and practical methods and solutions to my work with new customers. I love working for this cutting-edge company as its core values are extremely client-centric.”

Joining the team as an account manager, Marie-Lousie Du Toit explains what she is looking forward to in her new role: “I believe that attention to detail is a key component of being a trusted adviser and I am excited to bring my relationship-building skills to Conker.”

Jacqueline Mostert, new key accounts manager, has over 10 years’ experience in the client consultative space and comments: “I am driven by a passion for people, building trustful relationships and making a difference to my customers’ tech experience.”

In addition to the new hires, Taryn Ward has been promoted to Head of Business Development. She comments: “I am excited to be part of Conker’s growth journey. Working with a team that is passionate about finding solutions that help our customers maximise their business efficiencies and productivity is extremely rewarding.”

2023 is set to be another busy year for Conker and the expanding team will be crucial to support Conker’s continued growth. Conker CEO James Summers adds: “We are delighted to celebrate Taryn’s promotion and welcome Lwazi, Keshny, Dannida, Jacqueline and Marie-Louise to Conker. It’s great to meet new team members who are fully engaged with our mission to help companies match with the perfect tech for the job at hand and who will help in our continued growth.”