A forward-thinking process analysis and strategy are essential to implementing intelligent transport management software. In a new partnership, Euro-Log AG is combining its platform-based, digital transport management solution with the supply chain expertise of Deloitte. By merging their services in this field, the companies have created a powerful package that boosts the agility and resilience of supply chains.

Many businesses are increasingly feeling the pressure of unreliable supply chains, a lack of transparency and super-slow management processes in global transport. More than ever before, these companies need to manage their global supply chains in real-time using transport management platforms. IT services provider Euro-Log AG has forged a powerful partnership with Deloitte, combining the Euro-Log logistics platform with Deloitte’s comprehensive supply chain expertise to deliver even more effective solutions for global transport management.

In an initial phase, the Euro-Log AG transport management system will be deployed in Deloitte’s Supply Chain Control Tower (SCCT), an integrated data cockpit that provides access to virtually all levels of the supply chain. If there is an issue in the chain, the transport management system sends out an alert if a certain threshold value is exceeded. With the help of rule-based mechanisms, the system then suggests alternative transport routes, different modes of transport or new transport service providers. Euro-Log is also strengthening the Control Tower by adding global tracking solutions, which can even provide timely warnings of any delays in customs processing.

Countless Euro-Log customers and users of the Supply Chain Control Tower will benefit from this additional information and enhanced ability to control events in the supply chain. This includes users in the automotive sector: a familiar industry for Euro-Log, which has launched multiple automotive supply chain solutions and won a number of industry awards.

For Euro-Log CEO Jörg Fürbacher, this partnership represents a unique opportunity for global companies in an era of acute crisis: “This combination of competencies from both companies will enable customers to quickly analyse and identify process improvements, make rapid changes and safeguard their supply chains”, says Fürbacher. His words extend to the second phase of the partnership, which will involve rolling out both services in global companies. Fürbacher emphasises how quick and cost-effective it can be to implement the modular Euro-Log Transport Management System: “Often, in an initial phase, it only takes a few modules to stabilise a global supply chain; there is no need to invest enormous sums”.

Deloitte is also convinced of the potential of the complementary services. “Our partnership with Euro-Log is a highly valuable addition to our company, as we’ve demonstrated in joint projects with various customers”, says Tobias Exler, Deloitte Partner in Supply Chain & Network Operations. “We’re pleased that this partnership will enable us to expand our toolbox in this area – the Connected Supply Chain Solution, our Supply Chain Centre of Excellence and the Supply Chain Control Tower”, adds Stefan Klang, Deloitte Director in Supply Chain & Network Operations.

Euro-Log and Deloitte have already demonstrated how effective this partnership is in a joint connected supply chain project in the automotive sector. In this successful project, the companies showed that the rapid implementation of a digital, intelligent transport management system is a logical extension of process advice and support. This finely tuned partnership will enable many companies to achieve a resilient supply chain in the shortest possible time frame.

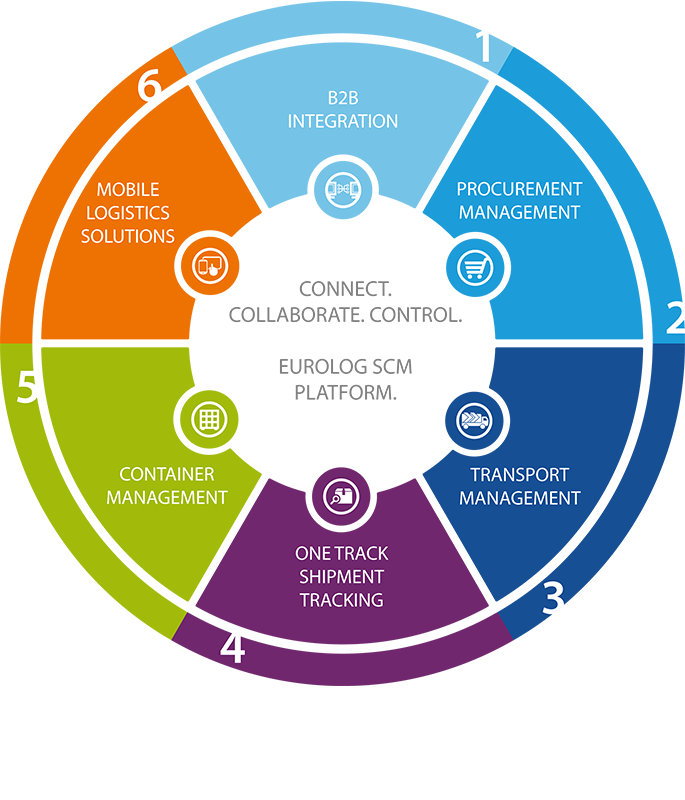

Founded in 1992 as a joint venture between Deutsche Telekom, France Telecom and Digital Equipment, EURO-LOG AG has established itself as one of the leading providers of IT and process integration solutions in the logistics industry. Since the beginning of 2018, EURO-LOG AG has been part of the global SupplyOn Group. With individual solutions such as B2B integration, procurement management, transport management, ONE TRACK shipment tracking, container management and mobile logistics solutions, the company ensures transparency along the entire supply chain. International customers from a wide range of sectors – from automotive, e-commerce and retail to industry and logistics – rely on the integration solutions provided by EURO-LOG AG. From its headquarters in Hallbergmoos, Munich, EURO-LOG AG operates its own data centres and employs over 120 people.