Generix Group, a global provider of collaborative SaaS Software solutions for the Supply Chain and commerce ecosystems, announces Resource Management System, its warehouse resource planning and optimization solution. Facing the growing complexity of order flows and the problems of absenteeism and turnover, companies must be able to anticipate better. Generix Group combines, in a single solution, performance analysis and resource planning services to improve warehouse productivity. Resource Management System is a powerful tool that increases employee loyalty by improving the quality of life at work, which enhance the attractiveness of warehouse jobs.

Supply chain managers are dealing with several challenges in the warehouse: performance, flexibility, complexity and granularity of orders and volume variations. In addition, new parameters have emerged with e-commerce, such as customization, deadlines, and volatility, which require organizational hyperagility. RMS provides an answer combining the excellence of the customer promise and the optimization of the first cost item of the supply chain: resources, both human and material. By offering analysis and resource planning functionalities in a single solution, Resource Management System (RMS) is a new performance lever for the warehouse. The solution is available in SaaS mode and can be easily integrated with all the WMS solutions available on the market.

Anticipate needs of resources to reduce the costs

Increasingly erratic orders, absenteeism and difficulties in recruiting, the challenges faced by warehouses impact their productivity and costs. In addition, meeting the growing demand for new and more personalized services requires flexibility, both for operators and in production resources. Warehouse managers want to anticipate the need of resources by considering both the capacity of their staff and the volumes of work planned for each day to better manage their available resources. They must therefore better decide and anticipate the adequacy of their workloads and capacities to have a better visibility of their daily needs. With RMS, logistics managers maximize their resources by being able to measure their productivity, plan their resources and improve the commitment of their teams with a single tool.

Measure productivity to optimize logistics production resources

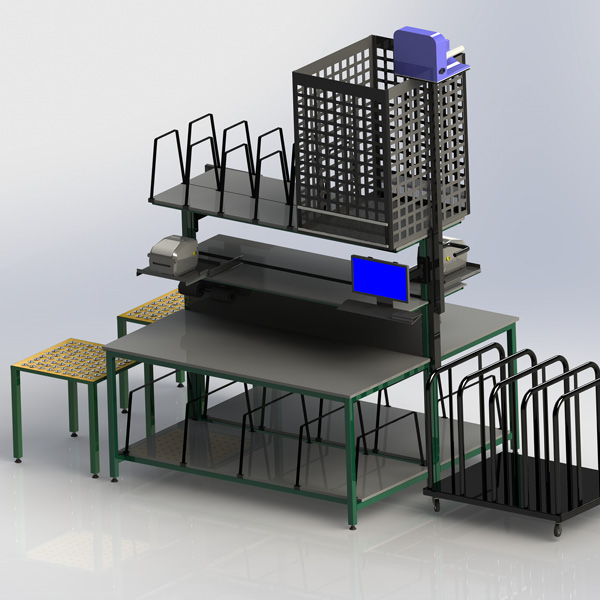

The unique combination of Labour Management and Resource Planning features allows optimal management of logistics production resources in warehouses, which are becoming larger and more automated. With the RMS solution, the forecasting and organization of human and material resources can be automated. Before investing in new equipment, site managers can be sure to get the most out of their existing resources.

RMS defines and automates load plan updates as finely as necessary: by task, by day, or even by hour. It calculates the average time required to complete the workload per shift (receiving, order preparation, packaging) and considers working conditions and employee profiles to adapt standards and set objectives. Lastly, it measures the productivity of operators, considering the context of execution, to feed the HR tools.

Develop operators’ versatility for more flexible warehouses

With more and more unitary references and preparations, site managers need to increase their flexibility to improve the ability of their resources to move easily from one task to another: an increasing requirement with variations in volumes and a growing demand for new services. With RMS, they plan the allocation of their resources, both human and material, dynamically and in real time. Artificial intelligence adds a layer of automation to the decision-making process: it anticipates the workloads to be executed and optimizes the distribution of resources, while adapting to the specificities of each warehouse, their objectives and constraints. Some warehouses have absenteeism rates of 50%: calculating real capacity and optimizing the use of the available workforce daily is a major challenge, especially for very large sites.

Resource versatility is more than ever a lever to increase flexibility and productivity, considering resource planning and individual performance per shift. RMS allows operators to move from one job to another during the same shift and perform different tasks, reducing fatigue and repetitiveness. The results: increased productivity, smarter scheduling for employees, daily management of employee absences, and a 50% rise in the reliability of capacity forecasts.

Better attract, recruit and retain employees, by strengthening its employer brand

Salary conditions are no longer a sufficient lever to retain employees. Faced with the difficulties of recruiting and retaining employees, the attractiveness of work sites and the diversity of assignments are a major challenge for both managers and human resources, especially since the use of temporary workers and staff training are very expensive. In addition, companies must address several societal issues: managing long careers with physical tasks, preventing work-related accidents, occupational diseases, and hardship. Thanks to the RMS solution, which dynamically assigns relevant tasks to operators and measures their performance, both individual and global, in an objective and transparent manner, warehouses can reinforce their attractiveness. By considering actual performance and monitoring learning curves, site managers can reward their operators and increase their motivation and loyalty by up to 20%.

Another motivator is gamification. Warehouse workers like to participate in challenges like counting their daily steps. Taking part in challenges keeps operators energized and motivated, allowing them to track their activity more accurately, the number of peaks per hour and their personal performance data compared to the group. RMS measures instantaneous productivity against a target.

“Today, logistics managers face a major challenge: accurately anticipate what they will be able to produce in the next few hours, days, months. How much would it cost, for example, considering new products, customers, etc. on an existing logistics capacity, while ensuring the loyalty of the teams in place? Warehouses need to be more flexible to meet their objectives and to anticipate and plan the allocation of their resources. With its data analysis, load calculation and forecasting, planning and

simulation services, RMS supports supply chain managers daily. The solution is also a way to get the most out of the existing before engaging in more complex and costly projects of integration of new means of production such as robots or automats, for example.”, explains Nicolas PICQUEREY, Chief Solutions & Services Officer for Generix Group.