When it comes to manufacturing high-quality fashion, Walbusch Group relies on Polymax Group, among others. The Chinese manufacturer under German management collaborates via the SCM software OSCA with the fashion specialist to bring transparency into the supply chain. At the same time, users of the tool save a lot of time because they are more effective without having to use tedious Excel lists, e-mail traffic and phone calls.

Three stories, large windows, white facade: From the outside, the Polymax Group factory in the Chinese coastal city of Ningbo could also be located somewhere in Germany. Only the company sign in Chinese characters indicates that the building is located in China.

Wolfram Geuting tries to spend at least two days a week in this factory. Fashion, or more precisely high-quality clothing, shoes, and accessories, are the passion of the CEO of Polymax Group. The German manager wants to be close to production, to the people who produce for him and his customers. That’s why the Asia expert, who pulls the strings for the company from his office in the business metropolis of Shanghai, likes to travel to Ningbo, which has a population of nine million. Ningbo is an ideal location for export-oriented fashion production: it is home to the most important Chinese port.

Geuting is well known in the industry: He has worked for Steilmann SE and NTS, among others. He feels at home in China. Since June 2022, the German has driven in another peg – as Managing Partner of Polymax Group, which was founded in the early 1980s by entrepreneur Ulrich Maeder. The now 73-year-old chairman is no stranger to the industry either. For more than 40 years, he has been regarded as a pioneer of German-Chinese economic relations and sustainable production in China: As early as 2001, the Zhejiang Province awarded him the “Golden Magnolia Prize” for the “most socially responsible factory.”

Fair payment, compliance with environmental and social standards: According to Geuting, the fact that the Polymax Group did everything in its power to meet the highest standards in human, environmental and occupational health and safety laws decades before the introduction of the Supply Chain Act in Germany is one of the company’s success factors. “Add to that the high-quality standards and on-time deliveries,” the manager said. Customers who knock on his door place the highest value on quality and sustainability seals. ISO 9001 in quality is standard. In addition, the company is listed with the Fair Wear Foundation and BSCI. The group also complies with the OEKO-TEX Standard 100.

Even though worker-friendly overtime regulations, modern production machinery and fair wages impact the profit margin, Geuting cannot think of any alternative. “We can report to our customers that 80 percent of our employees have been with the company for more than 18 years,” he explains. Some men and women have spent their entire working lives at Polymax – and 25 even live in a wing of the factory. They benefit not only from the fact that they have no commute to work, but also from the extremely inexpensive housing: they pay only the ancillary costs.

The success story in Ningbo has now been going on for almost three decades. 210 employees work in the factory. In addition, there are more than 30 in the various offices. Over the years, entrepreneur Ulrich Maeder has not only established offices in Macau and Shanghai, but also in Bangalore (India) and Dhaka (Bangladesh). In Ho Chi Ming City (Vietnam), two experts work in quality assurance. And in London and St. Augustin near Bonn, employees are active in customer acquisition.

Outdoor jackets, cashmere sweaters, silk shirts: the production of high-quality clothing has long since ceased to be the group’s only area of business. Experts also work in quality assurance, procurement services and executive consulting. In order to supply around 8.3 million garments per year to what are now 33 customers, the factory in Ningbo is no longer sufficient. Polymax cooperates with 18 other producers in Asia, the majority of which are located in China, three manufacturers in Bangladesh, two in Vietnam and one in India. Because the company has spun a large network and built up a lot of know-how and technology, it also acts as an agency for some customers. “For small customers, we offer a complete package – from fashion design to delivery. Then all they need is an office and a warehouse,” Geuting reports.

High sustainability standards, high quality, high delivery reliability: the Polymax strategy (“we don’t want to be the biggest, but we want to be the best”) is appreciated by brands of the Walbusch Group, the outdoor clothing specialist Schoeffel, the equestrian fashion supplier Ariat, the fashion label Carlo Collucci and the management of FC Bayern. For the latter, Polymax produces many items for the fan shop – from shoe bags with FCB logos to backpacks.

Polymax is regularly attested top performance – not in terms of quantity, but in terms of quality and reliability. Schöffel, for example, awarded the company “Supplier of the Year” in 2016 and 2018. “If you want to stay at a high level, you have to keep investing in technologies to stay at the cutting edge,” says Geuting. This applies to production equipment just as much as it does to the software landscape, for example.

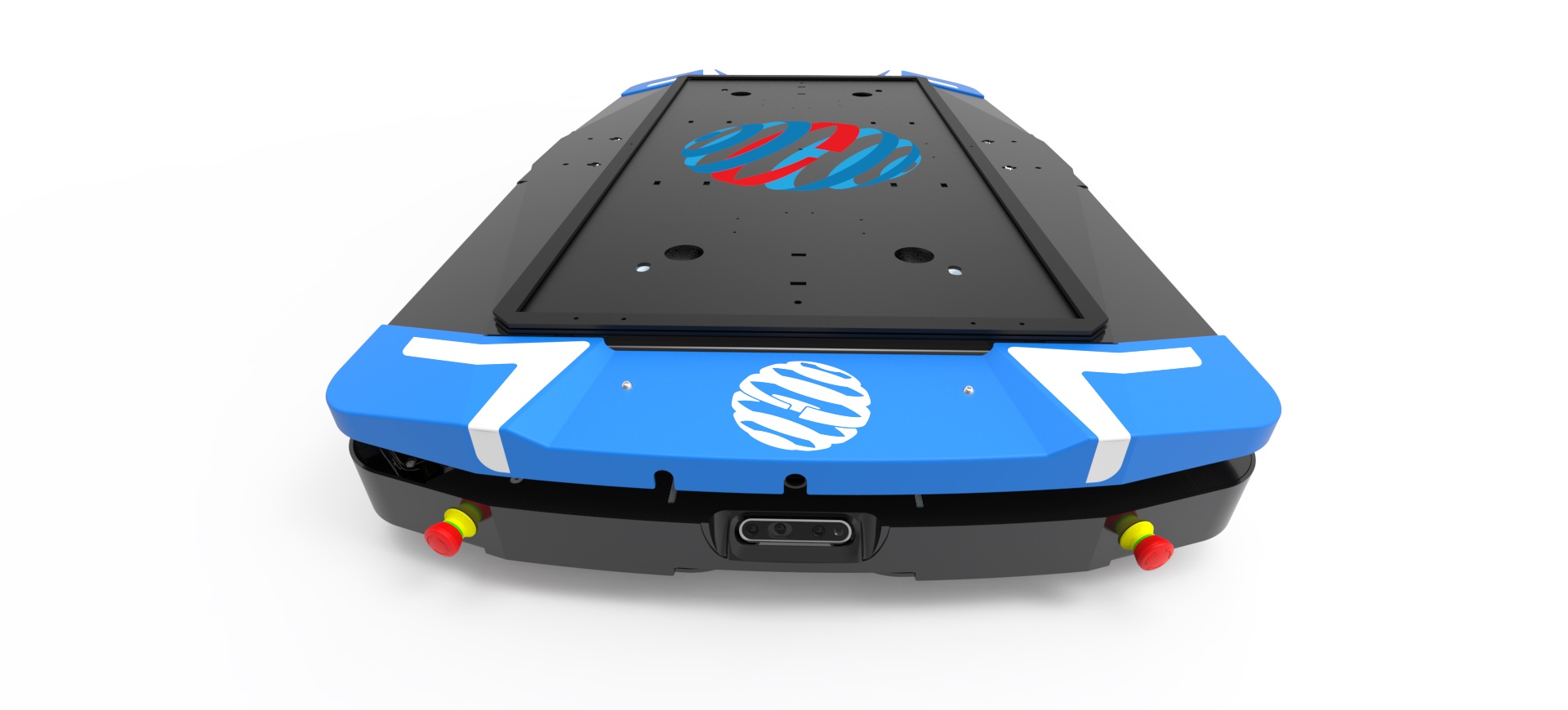

There is news to report from the IT department: At the beginning of 2023, Polymax Group started working with the SCM software OSCA from the Bochum-based software house Setlog. Geuting was already familiar with the web-based tool when the IT experts at Walbusch Group in Solingen approached him about introducing the software.

The Walbusch Group has been using OSCA DC (Digital Core) from Setlog since the end of 2021 to gain transparency in the supply chain and improve management, collaboration, and communication. The special thing about this: Walbusch Group was the first Setlog customer to rely on the new standard version of OSCA. This means that the processes of the Walbusch, Avena and Mey&Edlich brands were adapted to best practice examples from OSCA – and not vice versa. In this way, the group bypassed costly, customer-specific adjustments in the OSCA SCM software. The advantage: In addition to avoiding costs, the company saved time above all. Less than six months elapsed from the initial contact to the start-up of the software.

“We definitely wanted to avoid customer-specific adaptations and were able to bring transparency into the supply chain within a few months with the new software generation. We can inform our most important suppliers of changes in real time via a single tool. E-mails, phone calls and Excel spreadsheets are now a thing of the past,” reports Ralf Seggering, Head of IT and member of the management team at the long-established company. With Polymax, Walbusch Group integrated one of its main suppliers into the system. Other suppliers and forwarders of the company also work on the software.

According to Geuting, connecting as a supplier to the cloud-based software OSCA was done “in no time.” He downloaded the app, received a link and a password. Then, step by step, the functions Walbusch Group needed were unlocked, he said. “The three people who were to work with OSCA were already looking forward to it because they knew that annoying Excel lists, emails and phone calls would be eliminated from now on. Thanks to OSCA, there will also be no more discussions about who is to blame for a delay, for example,” reports Geuting. Just four hours of online training were necessary and the employees were able to start using the tool.

Walbusch Group’s strategy is that only Polymax should be the central contact for OSCA. Polymax therefore acts as supplier and agency for the German customer. The employees in China also maintain the data of Polymax partners in the system – the information is extensive. The tool is used for the following purposes, among others:

– the placement purchase orders,

– monitoring, controlling, and tracking of purchase orders,

– as a network between customer, supplier, carrier, and warehouse locations,

– for digital, collaborative teamwork,

– to manage delivery parameters such as timing and mode of transport, and

– as a database for important documents such as customs-related records.

All data is clearly visualized on OSCA’s dashboard. Walbusch Group benefits from the transparency and real-time control of supply chain partners. Polymax appreciates that- and less working time, too. Geuting calculated at least 20 percent time savings by using the software for each employee. Users are already asking him whether new customers use OSCA – or still operate with less convenient, proprietary systems or even still rely on Excel and e-mail in SCM. Employees have a clear preference, and so does Geuting. “I can recommend OSCA to buyers.”