Supply chain disruption: how to navigate ‘never normal’ distribution networks, by Andy Grygiel (pictured), CMO at project44.

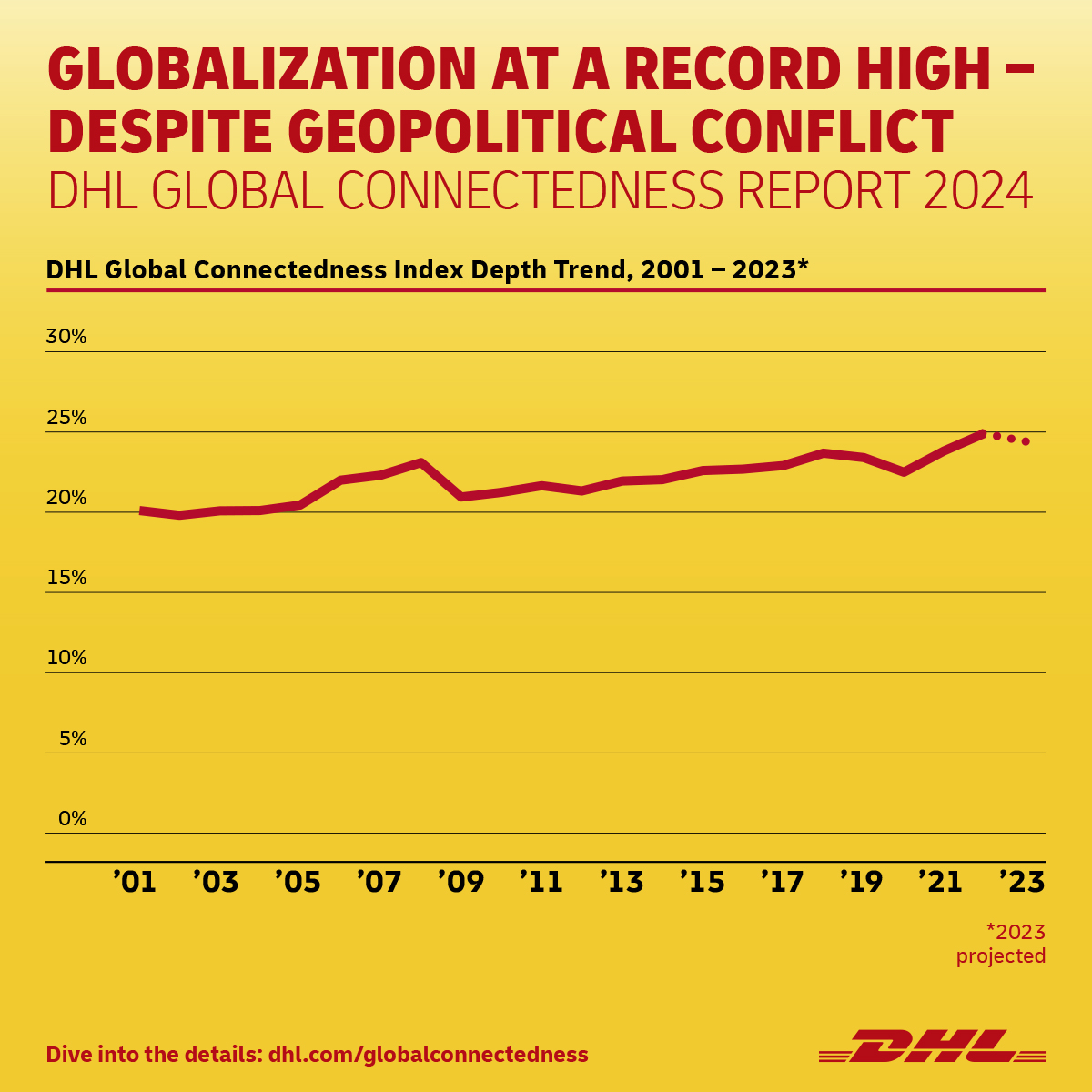

Today, managing an organisation’s supply chain can feel like an impossible task. Modern multi-tier logistics networks are spread between hundreds of suppliers across multiple continents—under this globalised model, businesses enjoy maximised distribution efficiency when all is well. However, with supply chains rarely running normally, they also suffer damaged transparency, resilience, and reputation at the slightest setback.

Unfortunately, growing numbers of high-profile supply chain disruptions—from the Ever Given container ship running aground in the Suez Canal to attacks on trade vessels by Houthi rebels in Yemen—show that organisations’ logistics systems require greater support than ever. Let’s explore the potential effects of these often-unforeseen challenges on your business and consumers, and how intelligent supply chain technology can help mitigate them.

Overcoming extreme weather as soon as it occurs

Weather forecasts aren’t simply there to help you decide whether you need to carry an umbrella—they also play a key role in worldwide trade. And as climate change triggers an increased number of extreme weather events, organisations today rely on weather condition data to ensure their supply chains continue to run smoothly. But access to this information is only the first step. Without the capacity to then quickly reroute vessels to reduce delays in trade routes, these events become increasingly difficult to overcome.

Take recent developments in the Panama Canal. This crucial maritime trade conduit, connecting the Atlantic Ocean with the Pacific, is responsible for 40% of worldwide vessel traffic. It’s also grappling with persistent drought conditions that have reduced its capacity by as much as 30%, leading to lengthy trade disruptions and reductions. The immediate cause is the naturally occurring El Niño warm-weather phenomenon. However, scientists also now believe that widespread climate change is behind prolonged dry spells and even higher temperatures in the Panama region.

Similarly disruptive weather events are taking place right across the globe. So, businesses need intelligent, high-velocity supply chain platforms to help them accordingly adapt their routes and make sure trade remains as seamless as possible. For instance, if severe weather impacts a city during the holidays, visibility into last mile solutions with real-time predicted ETAs will allow companies to make re-routing decisions faster. Then, they can alert their customers as soon as possible which helps to reduce support calls and increase overall customer satisfaction.

Reacting in real-time to unforeseeable obstacles

Unfortunately, there will also be occasions in which supply chain disruptions simply can’t be anticipated. You may have seen recent headlines of the attacks by Houthi rebels in Yemen on container vessels in the Bab al-Mandeb, a strait that connects the Red Sea to the Gulf of Aden and the Indian Ocean. Meanwhile, November 2023’s cyberattacks on Australian shipping ports offers another example of unpredictable events faced by organisations.

These crises underscore the importance of visibility, agility, flexibility, and resilience, all of which are powered by advanced supply chain technology. Simple location tracking of vessels is no longer sufficient; today, you need to be able to visualise which shipments and orders on which vessels are impacted by disruptions, plan a safe alternative route, and view and transmit an updated ETA to customers.

Let’s use the conflict in the Red Sea as an example. Businesses using a high-velocity platform not only benefit from real-time insights into vessels affected. They can also adapt their inventory management and downstream planning to limit stock outs. Improve operational efficiency by rerouting shipments to avoid putting vessels in danger and strategize on the most effective new shipping lines to use. Minimise costs by identifying and mitigating penalties and fees that occur because of upstream disruption. And, perhaps most importantly, boost customer satisfaction with transparent, proactive communication on delays to reset delivery expectations.

The importance of faster, more informed decision-making

Numerous recent supply chain disruptions have become global news stories. However, their publicity doesn’t always mean that customers will be any more sympathetic if goods are delayed, and regularly late deliveries can damage brand reputations. Organisations must harness competitive advantages—such as intelligent supply chain software—to stand out from the crowd and provide exceptional customer experiences. From avoiding any added costs that are usually passed on to customers to ensuring that goods arrive as soon as possible, the world’s leading shippers, carriers, and LSPs are now using advanced digital tools to transform supply chain operations from a cost centre to a revenue generator.

Ultimately, supply chains are never ‘normal’. Extreme weather events, unforeseeable geopolitical disruptions, and rapid technological evolutions mean organisations may never be able to expect their logistical operations to work smoothly every day. Instead, wielding all the available intelligence tools now at their disposal is the closest they can get to a frictionless, straightforward supply chain—and consistently delighted customers.

read more

Industry View: Secure Your Supply Chain Now to Beat Disruption