New data from intelligent planning technology provider Board International, reveals that senior supply chain professionals are placing a renewed focus on scenario planning in response to a volatile business landscape. According to the new Board 2024 Global Planning Survey, 73% (Global: 71%) of decision-makers are taking planning more seriously, with the Ukraine War, cost-of-living crisis, and ongoing supply chain disruptions acting as key catalysts.

Cyberattacks (Supply Chain Professionals (SCP): 36%; Global: 34%), labor shortages (SCP: 35%; Global: 36%), blocking of key supply chain channels (SCP: 27%; Global: 30%) and fluctuating oil prices (SCP: 34%; Global: 29%) top the list of key business threats that decision makers are currently making plans for.

Despite an emphasis on planning to help navigate this disruption, many supply chain professionals continue to face challenges planning effectively. The survey reveals signs of planning fatigue within many companies, highlighting a 14% decrease in how seriously companies are taking planning compared to last year. Similarly, just over three quarters (SCP: 77%; Global:73%) of supply chain decision makers admit their organization makes planning decisions based on assumptions. Together, these findings suggest that many supply chain professionals are struggling to implement data-driven decision-making. Nearly a third (SCP: 29%; Global: 29%) of respondents report that ineffective planning has impacted profitability, productivity and the ability to drive innovations, new products or services.

From Scanning to Planning

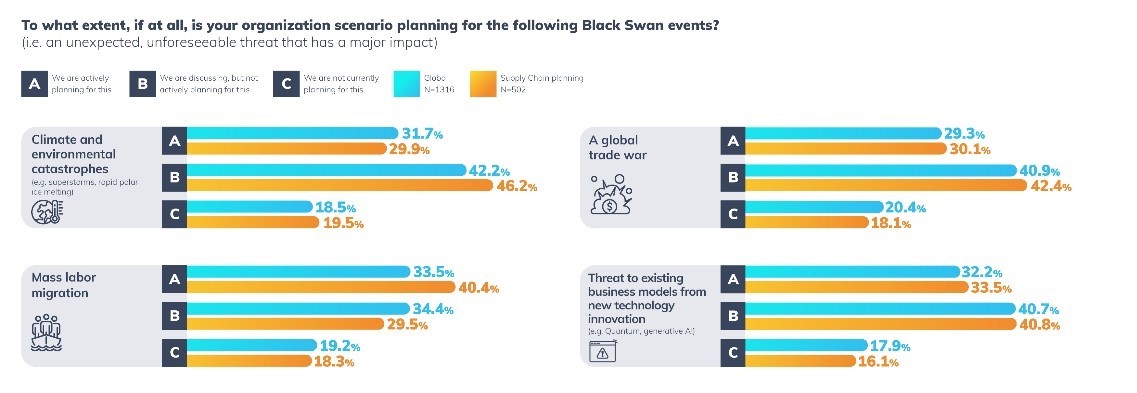

The survey reveals that too many companies are simply scanning for potential crises rather than actively preparing for them. For example, Board found that 43% (Global: 39%) of respondents are discussing rising tensions between China and Taiwan but only 29% (Global: 27%) are actively scenario planning for an escalation in the region. The lesson from Gray Rhino and Black Swan events like the conflict in Gaza or the war in Ukraine highlight how important it is for organizations to anticipate and mitigate the risk of geopolitical, economic and social disruptions, however unlikely they may seem. The survey also found that 72% (Global: 70%) of supply chain professionals usually disregard the most extreme scenarios when planning, suggesting most companies are leaving themselves open to risk should the unexpected happen. And often because it’s too difficult or time consuming for them to do so.

“Industry leaders face immense pressure to navigate a complex and unpredictable business environment. The need to shift from conversation to action around scenario planning has never been more important,” said Jeff Casale, Board’s CEO. “But in far too many cases, organizations remain limited by legacy tools that are prone to errors and siloed data – leaving them vulnerable to costly mistakes and outdated insights. To better compete, they need to be proactive about anticipating disruptive events, modelling calculated scenarios and aligning strategic, financial and operational plans.”

Supply Chain Cyber Security Threats

Adopting an agile and integrated approach to planning is critical for companies to drive increased flexibility, streamlined operations, faster time-to-market and improved collaboration and resource allocation in a rapidly evolving market landscape. However, the survey identifies a concerning agile planning gap that highlights a significant disconnect between aspirations and reality. The survey found that 76% (Global: 73%) of respondents globally believe their organization is equipped for agile planning, but only 14% (Global: 17%) have the right processes and technologies in place to make this a reality.

For companies looking to close this gap, the survey found three key barriers: poor data quality and governance (SCP: 46%; Global: 46%), ineffective processes based on largely manual activities (SCP: 43%; Global: 48%) and a lack of modern tools and technologies (SCP: 42%; Global: 43%).

Underpinning each of these barriers is an overreliance on static spreadsheets. The survey found 57% (Global: 55%) of supply chain planners globally use spreadsheets, like Excel, for at least half of their business planning – a source of potential risk due to limitations caused by manual data entry and lack of real-time data integration. The survey also found that 72% (Global: 71%) of companies fail to consider enough potential future scenarios when planning, which can also leave them unprepared for unexpected events.

Successful Agile Planning

Organizations are looking to AI to overhaul their approach as they shift towards data-driven, agile planning. 41% (Global: 46%) of respondents are exploring machine learning to improve decision-making, while 38% (Global: 44%) are looking to AI-powered business intelligence tools. A third (SCP: 33%; Global: 34%) of respondents also plan to adopt generative AI tools to enhance their decision-making process.

“By embracing intelligent planning tools and agile planning processes, companies can analyze internal and external data to plan for a range of eventualities, to drive more informed, proactive decision-making and improved business outcomes,” added Casale. “Over the next decade, companies that don’t shift to running their business on a fully integrated planning system will be facing an uphill battle.”

read more

Data Everywhere: AI in Logistics