Sensor supplier SICK has expanded its high performance multiScan and picoScan LiDAR ranges to make them even more powerful, compact and robust. With a variety of industry specific software applications that run on-device, SICK aim to take LiDAR sensor technology to new levels of performance, reliability and flexibility.

The modular multiScan 100 3D product family and compact picoScan 150 LiDAR sensors are customisable to suit a wide range of applications, with bespoke parameters, operation and integration. From robotic guidance and outdoor automation to SLAM, SICK’s sensor range is enhanced with new products and capabilities, including improved light performance and accuracy.

Select your variant: Configure your solution

SICK’s flexible 2D and 3D LiDAR product range and families are based on a common user environment and programming development platform. Fast data streaming, 2D and 3D object detection with field evaluation enhance the quality, security and usability of both the multiScan and picoScan. This enables companies to develop dynamic sensing profiles and scale their LiDAR capabilities, leveraging the data generated and customizing sensors to their specific applications and requirements.

Superior performance and robustness

SICK’s expertise in the field of 3D and 2D LiDAR technology enhances the robustness of both product ranges, improving accuracy, and providing ambient light immunity up to 100 klx (making them suitable for all lighting conditions). The picoScan and multiScan devices have a ruggedized design, with an anticorrosive coating, venting element and vibration resistance, making them resistant to shock, vibration and interference. Suitable for use in rough ambient conditions (such as fog, rain and bright sunlight) and harsh environments, both ranges have a selection of connectivity options and accessories designed for outdoor use.

The picoScan and multiScan products also have a contamination indication and the predictive maintenance system means sensors can notify the operator before the system is influenced.

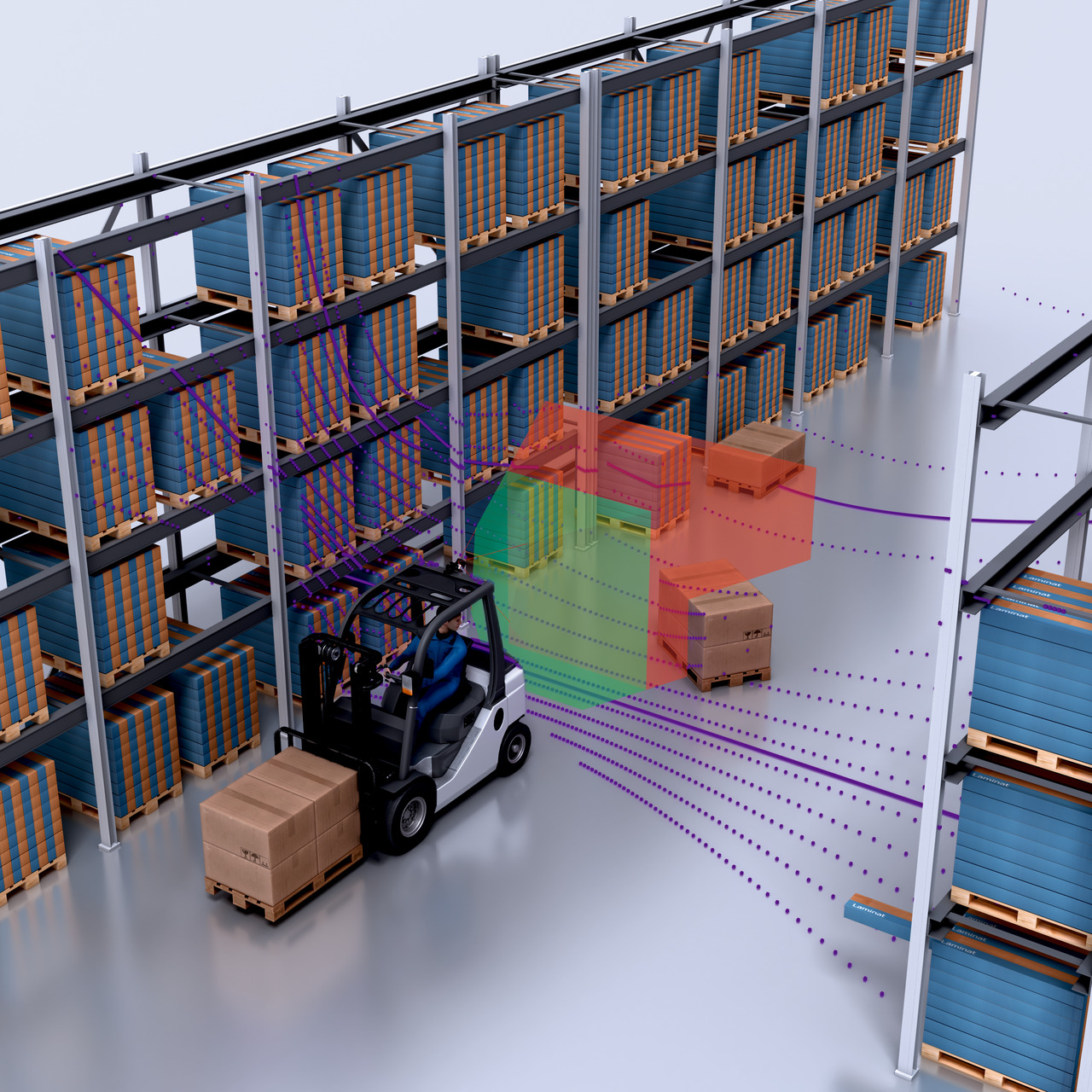

Based on time of flight (ToF) technology, SICK’s high value multiScan range delivers high quality 3D with simultaneous multiple measurements individually configured for precise detection and localisation. The multiScan 3D LiDAR range’s unique combination of high-density horizontal layers and 3D point cloud offers outstanding measurement performance and advantage in real conditions, including wide-area environment perception on large machines and outstanding measurement accuracy for access protection in stationary applications. Capable of reliably detecting drop-off edges and obstacles ahead, the range is ideal for anti-collision and environmental perception to support autonomous driving for outdoor automation.

With no blind zone and superior detection of small objects at a distance, the multiScan 100 is a product family of 3D LiDAR devices with 3D object detection and contamination indication on board. The multiScan 136 builds on the capabilities of the multiScan 100 platform by providing 16 LiDAR layers, including two HD layers, 65° coverage at 360° and 30 m range all round. Meanwhile, the multiScan 165 has the highest detection capability in foggy, rainy and dusty conditions. It offers the same 16 LiDAR layers, but with a narrower coverage angle and range of up to 60 m, and the upcoming multiScan 165S will provide PLb and outdoor safety.

Small in size, big in range and performance

The next evolutionary step from the popular SICK TIM sensor, with higher data streaming speeds and more precise localisation, the picoScan 150 compact 2D LiDAR sensor is one of SICK’s highest angular LiDAR devices, with a rotary resolution of 0.05 degrees. The increased light suppression performance helps outdoor performance reach unprecedented levels. The multiScan family has a wide range of accessories, including mounting kits, connection boxes, gateways and reflectors. The picoscan 150 comes in three variants – Core, Prime and Pro, with a working range from 0.05 m up to 120m. Each model has a different specification to allow easy selection of a device for a specific application.

Easy to integrate into various environments, with a range of software interface options, the picoScan 150 is one compact sensor for multiple applications and it ticks all the boxes in terms of range, resolution, accuracy, field of vision, scan rate, power consumption and connectivity. Its high robustness is perfect for harsh and challenging applications, such as mobile platforms, outdoor automation, mobile robots, building security, interactive 3D studios, logistics automation and security protection.

Nathaniel Hofmann, SICK UK Market Product Manager – Machine Vision and Measurement Systems, says, “These are two great product families with new features and capabilities that expand the capabilities and possibilities of LiDAR sensor technology. We are continually growing and enhancing our LiDAR sensor range, based on a commonality of user environment that ensures products are easy to use, customisable, robust and consistent.

“We are winning high-profile projects because of the new light immunity and resolution capabilities of the picoScan and multiScan ranges, across a huge range of applications and industries; from robotics to interactive art installations, intelligent infrastructure to outdoor automation. Our modular, customisable sensors fit almost all applications, with the exceptional reliability and performance you expect from SICK.”

similar news

MultiScan Master Data Solution Available