Danish homeware chain Søstrene Grene has deployed automated packaging equipment from CMC to help optimise its eCommerce operations. Søstrene Grene is a retailer with more than 50 years of history, yet is relatively new to eCommerce, having only started offering online shopping to customers four years ago. With a retail presence in 16 countries and an online offering to 11, the firm offers a wide range of competitively priced homeware and accessories, crafts, kitchenware, gardening equipment and other goods.

A particular challenge when fulfilling eCommerce orders is the size and shape of the typical basket, and the variation of products therein, which could range from a small set of pens up to a full-sized chair, for example. The time it was taking to pack an order in its current DC in Denmark – soon to be joined by a new facility in the Netherlands – led to Søstrene Grene’s Chief Supply Chain Officer, Claus Tjærby, to lead a project to both reduce this time as well as reduce the amount of packaging used.

“Picking the order was not that challenging, but packing the order was very time consuming for us,” he says, “so the combination of time consuming orders, a lot of fragile items, and then the fact that our business was just growing massively meant we had a huge labour pool when working in peak seasons.”

Multiple Benefits

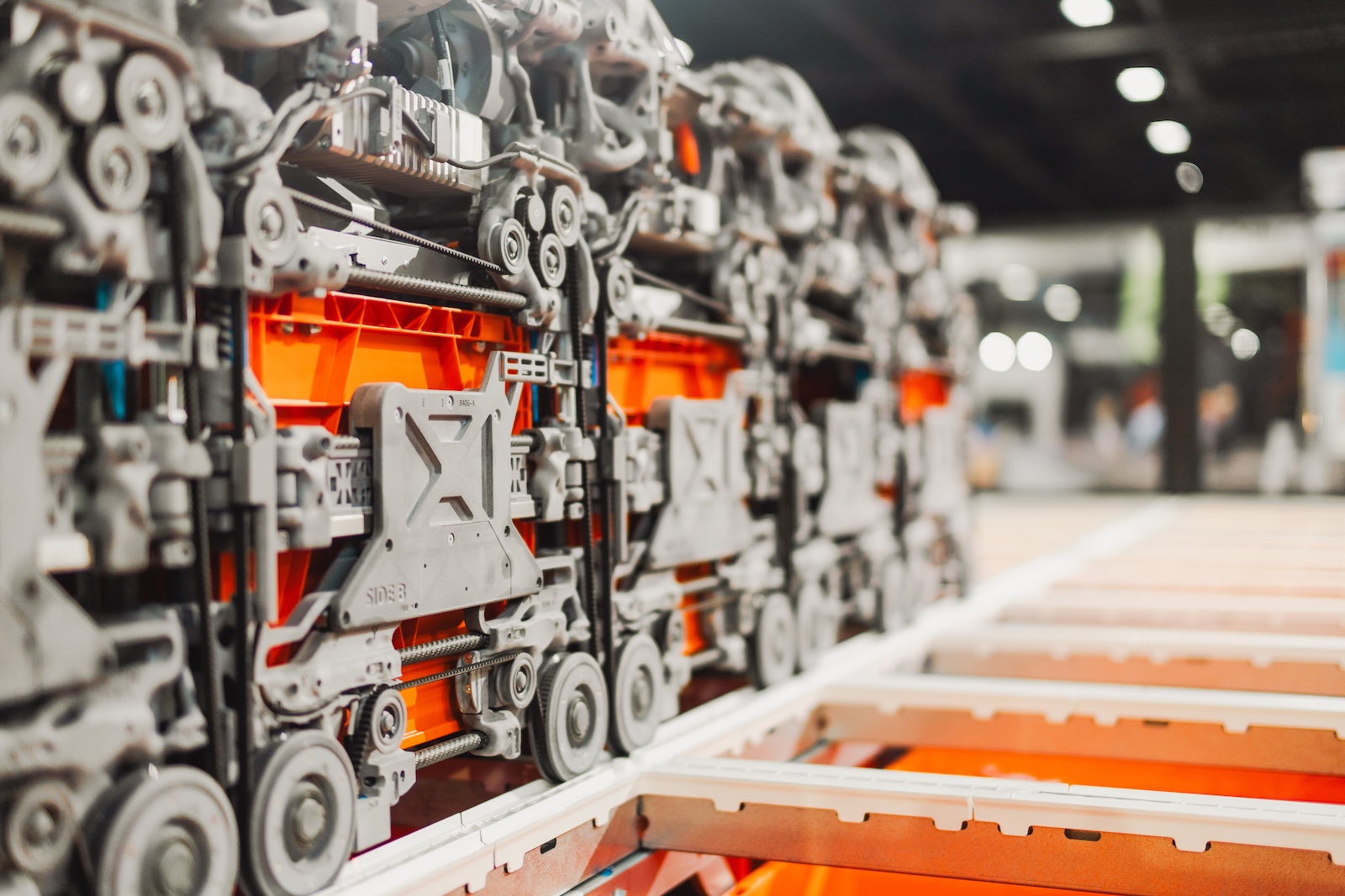

Through its Danish distributor Antalis Packaging, Italian sustainable packaging equipment manufacturer CMC Packaging Automation helped meet that challenge, bringing multiple benefits including a reduction in Søstrene Grene’s carbon footprint by supplying its CartonWrap technology to the Danish company. The automation in the DC means goods dispatched by Søstrene Grene to its online customers are now packed more efficiently and effectively. “Now it’s not one of 200 individuals who decide how they want to pack, it’s automated,” continues Tjærby, “and we use less packing material. Also, the size of the shipping box itself is much tighter now, so basically we can put more boxes on one pallet, which reduces transportation costs and, more importantly, reduces CO2 emissions from the transportation side of our business.”

The CMC solution means Søstrene Grene is able to pack its goods more densely, reducing the amount of air inside the individual parcels and packages. “With this system from CMC, we not only use less packing material, but we have also been able to shift from plastic packing – bubble plastic to protect the products – to paper-based packaging. So, all in all, a lot of individual contributions to an overall lower emission.”

Today’s younger consumers are increasingly seeking out sustainable retailers, and the packaging in which their items arrive is subject to considerable scrutiny, especially on social media where the worst offenders are routinely named and shamed on platforms such as Instagram, YouTube and TikTok. But when it comes to who will bear the cost of greater sustainability in retail, the answer is not often the end consumer. No, as businesses vie to attract buyers with competitively priced goods, it’s sometimes not feasible to pass on any additional costs to the customer. Furthermore, margins are tight in retail – tighter today than they’ve ever been – so any sustainability initiative cannot come at a high cost to the retailer.

Sustainable Solution

In light of this, Søstrene Grene has managed to offer a sustainable solution whilst reducing its overall packaging costs. “As a business, [moving to sustainable packaging] is something we want to do,” says Tjærby. “And then you also have the requirements from the authorities, legislation, which is becoming more and more strict. With different kinds of taxes applying to the amount of packaging material, there is an obvious cost saving factor in reducing paying material.“

The addition of a faster packaging solution from CMC that right-sizes outbound goods also greatly smooths flow through the warehouse. “It has helped the flow because we can pre-pack a lot of our more fragile items, such as glasses. When you ship them, they have to be wrapped first. With the CMC machines, we can now pre-pack it and then, once we get the order, we have a much more consistent flow, which is much easier for us to handle. And when you don’t have such a vast number of people on the floor – people running around all the time, with a lot of boxes, with a lot of paper – you can design a cleaner flow way. It’s much more easy to control and to oversee the operation.”

Although this was CMC’s first Scandinavian project, Tjærby couldn’t be more complimentary about the service offered: “We had very good cooperation with CMC. We are happy with the support and with the cooperation from their side. We feel that they were quite eager to make this a success, because we were a platform for their market entry, so from their side we had their attention. Their Scandinavian distributor for the products, Antalis, is now giving us the support, which is also what we need. So, in terms of cooperation with CMC and their distributors we are happy.“

With both the hardware and the packaging materials coming from a single supplier, compatibility is assured, says Tjærby: “It is an advantage to have one point of contact; with one supplier for the machine and another supplier for the consumables if something is not functioning well they can point the finger of blame at each other. It is not a possibility here, because they are the same company, and have the full responsibility to make it a smooth flow. That’s definitely an advantage, no argument about that.”

Whilst investing in a full automated packaging machine has reduced the need for Søstrene Grene to recruit so many temporary workers during its mid-October to early-January peak, there are still some aspects of its picking and packing process that still need to be automated. “That will be something we will dive into this year,“ concludes Tjærby. “We hope to be able to also optimise the last manual parts of our operation.”

similar news

CMC Machinery rebrands to CMC Packaging Automation