Samsara has just launched more than a dozen new safety and AI-powered tools designed to make physical operations safer, smarter, and more efficient than ever before. Launched at its annual Beyond conference in San Diego, David Priestman reports.

Fuelled by Samsara’s open platform, these first-of-their-kind solutions empower organisations to operate smarter and fundamentally alter the industry’s approach to the safety of frontline teams. These new solutions include AI-powered safety tools, a new connected wearable, advanced routing and navigation capabilities and enhanced maintenance tools.

“We’ve entered the age of intelligence, and AI is helping our customers operate smarter,” said Sanjit Biswas, CEO and co-founder of Samsara. “We’re partnering with our customers to build products that help them run safer, more efficient operations and protect frontline workers while saving millions of dollars.” Samsara has invested more than $1bn in research and development to date. By leveraging its more than 14 trillion data points, the company is continuing its innovation leadership with the launch of several new products and enhancements.

Samsara has invested more than $1bn in research and development to date. By leveraging its more than 14 trillion data points, the company is continuing its innovation leadership with the launch of several new products and enhancements.

Reward drivers, spot risks and prevent incidents in real time

Driving ranks among the top 10 most dangerous jobs. Over the past decade, there has been a 49% increase in fatal crashes, coupled with a 40% increase in associated insurance premiums in the USA. Samsara offers advanced technology to help detect risky driving events, such as phone use or speeding; now, several new AI-fuelled features have been added to improve fleet safety and reward safe driving:

● AI Multi-Cam: Drivers can now add up to four additional HD cameras, providing a 360-degree view to reduce blind spots, all accessible via an in-cab monitor. In addition, the AI Multi-Cam actively notifies drivers in real time of hazards, such as pedestrians and cyclists. Whether using a Samsara camera or a third-party device, administrators can retrieve historic video footage and corresponding audio to help quickly resolve incidents.

● Weather Intelligence: Administrators can now overlay real-time weather data pulled from the National Weather Service onto the existing dashboards to view and alert workers of imminent threats such as fire risks, heavy rain and more.

● Safety Coaching for Lean Teams: A new set of customisable features helps administrators with lean safety teams to scale driver coaching and recognition with AI and automation. AI analyses hundreds of risky driving events – considering factors such as severity, frequency, road conditions and total drive time – and automatically sends low-risk behaviours to drivers for self-coaching and escalates higher-risk events to managers. Furthermore, AI provides insight into big-picture behavioural trends across drivers and trips, so managers can coach based on driving patterns rather than just isolated incidents.

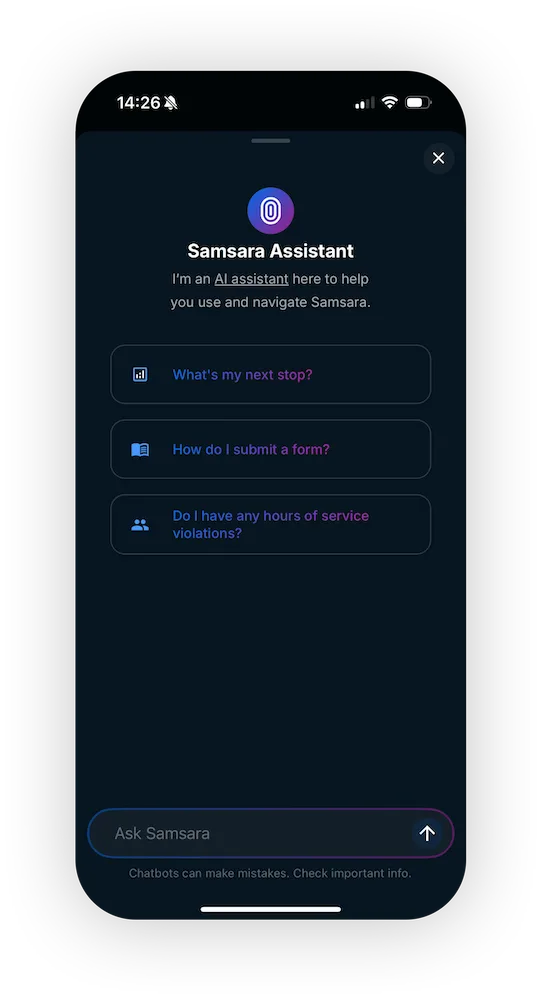

● Revamped Driver App: As the No. 1 driver app in both major app stores, the Samsara app now includes TikTok-style training videos to boost engagement and end-of-day reviews to help with driver coaching. Designed to act as a companion for drivers throughout the day, the app now offers new gamification features and recognition tools to reinforce positive, safe behaviour. For example, administrators can send gift cards that can be redeemed at popular dining, entertainment and shopping locations directly through the app.

“Getting drivers home safe is one of our primary goals at Samsara, a priority we share with every one of our more than 10,000 customers,” said Johan Land, SVP of Product and Engineering at Samsara. “Thanks to rapid advancements in AI technology, we’ve been able to build new products that are now empowering drivers to make better decisions on the road and equipping safety teams with the tools for faster, more effective feedback. AI is increasingly becoming a powerful ally in protecting drivers, and Samsara is at the forefront of this trend.”

Worker Safety Beyond the Vehicle: New wearable joins the fleet

The need to keep frontline teams safe extends beyond the vehicle to both local jobsites and remote locations. To help protect frontline workers outside of the vehicle, Samsara is introducing the Samsara Wearable. The new connected device is powered by the Samsara network of millions of devices and enables quick response and protection in any environment. With the addition of the wearable, organisations now have access to a holistic safety offering that can help predict risk, reduce accidents and alert administrators to urgent needs of their frontline workers. The new Samsara Wearable offers several benefits, including:

● More than one year of battery life: The Samsara network replaces the need for cellular connectivity, equipping the Samsara Wearable with a battery life of more than one year. This charge life far surpasses the industry standard of 24 hours, providing reliable access to everywhere customers operate.

● One-click protection: With one click, workers can connect to emergency services, who can immediately pinpoint their precise location and access a real-time audio recording of the situation. The small, lightweight device is easy to use and gives workers an added layer of protection in the field.

● Fall detection: The Samsara Wearable can automatically detect and respond to falls in situations such as slips on icy pavements and falls from heights such as scaffolding, cranes or trailers.

● Proactive threat alerts: In the case of severe weather or wildfires, fleet managers can proactively check in on workers and alert them of the unsafe conditions via push notifications to the device.

● One platform: Samsara connects driver and worker safety in one system, allowing for faster response times and visibility across the entire fleet.

Smarter, Easier Routing

Historically, commercial fleets have relied on a patchwork of incomplete maps and manual processes to plan routes and guide drivers. These legacy maps are updated as infrequently as every one to five years, leading to inefficient routes, missed delivery windows and increased driver stress. Samsara’s new Route Planning and Commercial Navigation products offer a modern, integrated alternative that helps fleets cut costs, stay compliant and deliver more reliably.

● Route Planning: Building on existing routing capabilities, Samsara now integrates directly with fleet operators’ sales systems to pinpoint the most efficient routes and delivery schedules for customers’ fleets. These advanced routing capabilities consider variables such as vehicle limitations, compliance requirements for drivers, customer delivery windows, as well as traffic and weather patterns, to stay within promised delivery windows and avoid unnecessary fuel usage. Early Samsara data suggests a 15% reduction in the number of vehicles required for deliveries and a reduction of manual back-office routing time, turning routing into a competitive advantage.

● Commercial Navigation: Samsara can now overlay fleet-specific restrictions such as weight, height and hazmat directly onto standard digital maps to provide more accurate turn-by-turn directions. By combining this insight with information such as hours of service within the Samsara Driver App, drivers can access everything they need in a single location to remain compliant and on time.

“Samsara has made a significant impact on our operations, saving $7.75 million annually across our three fleets by helping us optimise planned versus actuals route improvements,“ said Andy Yearout, VP of Transportation & Logistics at Mohawk Industries. “With the new Route Planning capability, we expect to see a reduction in daily route planning time from hours to minutes.”

Asset Maintenance and Visibility

Vehicle maintenance violations comprise 60% of all US Department of Transportation offences, resulting in substantial financial penalties and costly vehicle downtime. To help minimise these disruptions, Samsara has introduced several new preventative maintenance features, including Vehicle Inspection, Fault Code Intelligence, Automated Work Orders and Level Monitoring.

● Vehicle Inspection: Now, drivers can simplify the vehicle inspection process by automatically converting inspection notes from voice to text. In turn, managers can ensure that reports are properly completed by viewing drivers’ walkaround paths, the duration of the inspection and quality of the report photos. To help maintain compliance, the platform triggers real-time alerts for missing vehicle inspections, monitors FMCSA data, reviews inspection result and violations and audits driver behaviour. This AI-powered functionality works in low-connectivity and loud environments and results in faster inspections and streamlined repairs and maintenance.

● Fault Code Intelligence and Automated Work Orders: This optimisation extends to the back office, where fleet administrators can view the Vehicle Inspections in a unified dashboard. Fault code intelligence automatically deciphers the codes and uses AI to create maintenance work orders. In addition, Samsara now offers AI invoice scanning to help quickly upload external vendor invoices into the platform, reducing administrative time and errors associated with manual entries.

● Level Monitoring: With level monitoring, organisations have near real-time visibility into levels across a wide range of tank types. This insight enables improved tank utilisation and the ability to optimise inventory.

“Physical operations organisations are at the forefront of adopting AI because it saves lives. It also drives a more efficient use of labour, fuel and energy savings, and higher utilisation of capital assets,” said Kiren Sekar, Chief Product Officer, Samsara. “With the rollout of Samsara’s new AI-powered solutions, we are giving physical operations leaders a real partner on both safety and efficiency.”

HappyRobot Integration

Continuing its commitment to bring cutting-edge AI to its customers, Samsara today announced a new partnership with HappyRobot, a pioneer in AI-powered voice solutions for the logistics sector. Samsara Ventures also announced an investment in HappyRobot to reflect our belief in its vision and the transformative potential of agentic AI.

HappyRobot offers truly human-like agentic AI to automate communications via phone, email and text to boost efficiency and improve customer satisfaction. Organisations can use agents to automatically call drivers or customers to notify them of shift details or order status, to navigate phone trees, negotiate contracts with freight brokers and even for screening, hiring and onboarding.

HappyRobot users are automating more than 20 million conversations annually, reducing call times by half and cutting operational costs by a third. Existing Samsara customers like Werner are seeing tremendous value from HappyRobot’s technology.

similar news