As Europe is experiencing extreme heat it is essential that supply chains, especially those handling temperature-sensitive goods, face multifaceted pressures on infrastructure, vehicles, and workforce. Let‘s explore these mounting challenges and outline vital adaptation strategies.

The Accelerating Trend of Heatwaves in Europe

Europe is warming at roughly twice the global average, a critical shift requiring integration into long-term supply chain planning. The summer of 2025 has already seen significant heatwaves, with southern European temperatures regularly topping 40°C. Following 2024, 2025 is projected to be the second hottest year on record, with temperatures like Portugal’s 46.6°C already broken. By 2050, intensely hot days in major European cities, home to over 70% of the population, could more than triple, severely challenging urban logistics.

The Indispensable Role of Road Transport in the European Supply Chain

Road freight transport remains an indispensable backbone of the European economy. In 2024, EU road freight reached 1,869 billion tonne-kilometres, a 0.6% increase from 2023, reflecting consistent demand across vital supply chains like food and agriculture. Poland led EU road freight in 2024 with nearly 20% (368 billion tonne-kilometres), followed by Germany, Spain, France, and Italy, together accounting for 67%. Within the specialized domain of cold chain logistics, road transport is the most frequently utilized mode, particularly for short to mid-range distances. Refrigerated trucks and vans are essential for direct deliveries to stores, distribution centres, and even directly to consumers, facilitating critical last-mile deliveries for perishable goods across Europe.

Fragility of Temperature-Sensitive Goods

Temperature-sensitive goods encompass a broad spectrum of products vital to daily life and industry. These include fresh produce, pharmaceuticals, and biological products, which are inherently perishable and require stringent temperature and humidity control from origin to destination. For instance, avocados need 6°C, blueberries 1°C, and bananas 16°C. Even minor ‘temperature excursions’ can cause significant spoilage and safety risks; a mere 1°C increase at low temperatures can halve a product’s shelf life. Fresh produce has little buffer time, making it highly vulnerable to temperature-induced disruptions. This inherent fragility highlights the critical need for robust cold chain management in a warming climate.

The Direct Impact of Heatwaves on European Road Transport

1. Road Infrastructure Degradation

Prolonged high temperatures severely degrade European road surfaces. Asphalt can melt under intense heat and the continuous stress of heavy traffic, particularly from trucks with a maximum allowable mass of up to 40 tons. Concrete slabs also expand and buckle. These heat-induced deformities create safety risks, damage vehicle suspension, and cause widespread delays, undermining resilient transportation networks. Recognizing this vulnerability, EU climate adaptation policies for 2023-2025 mandate resilience upgrades for critical infrastructure, including roads. Broader estimates suggest the EU needs roughly €260 billion in climate-related investments annually by 2030 for sectors like energy, transport, buildings, etc.

2. Driver Health and Productivity

Heat stress significantly impairs driver productivity and elevates accident risk, a known occupational hazard. Most professional drivers experience fatigue, largely due to heat and poor in-vehicle cooling. This directly reduces concentration, increasing accident likelihood. Such harsh working conditions worsen Europe’s truck driver shortage, which stood at 233,000 unfilled jobs in 2024 and could reach 745,000 by 2028, making talent recruitment and retention even harder.

3. Vehicle Performance and Breakdowns

Soaring temperatures in Europe are causing more vehicle breakdowns, particularly for older trucks prone to overheating and mechanical failures, leading to delivery delays. This extreme heat also drastically increases maintenance needs — stressing cooling systems, accelerating tire wear, and fatiguing components — which elevates operating costs and strains schedules. This mounting burden means investing in newer, heat-resilient vehicles is no longer just a sustainability goal but a critical necessity for logistics companies to maintain operational reliability and cost control. To address this growing risk, some logistics companies are proactively investing in newer, heat-resilient fleets. For example, Girteka Logistics operates a modern fleet of 6,000 fuel-efficient Euro 6 trucks, with an average age of just 2.5 years. These vehicles are equipped with integrated CO₂-reduction technologies, advanced safety systems, and telematics for real-time performance monitoring — ensuring greater resilience during extreme weather and supporting operational reliability.

Operational Disruptions and Economic Costs of Extreme Heat

Extreme heat fundamentally short circuits and wears down transport systems, leading to intricate interdependencies across various supply chain segments. Transportation disruptions manifest in multiple forms, including rail service interruptions due to mudslides (e.g., the Paris-Milan route) and critically low water levels in major commercial waterways like Germany’s Rhine River, which force barges to operate at only 40-50% capacity. This significantly inflates freight costs and impedes the transport of commodities, frequently rerouting traffic to already strained road networks. The 2025 heatwave is estimated to reduce European economic growth by 0.5 percentage points of GDP, a disruption comparable to half a day of strikes for each day with temperatures exceeding 32°C. Southern European countries, such as Spain, faced even higher losses, with an estimated 1.4% reduction in GDP. ECB research (July 2025) confirms heatwaves’ prolonged negative effect on regional economic activity, with output 1.5% lower after two years.

Despite a general decline in European road freight spot rates in Q1 2025 (due to subdued demand and trade war uncertainties), diesel prices rose by 4.8% (Q1 2024 vs. Q4 2024), maintaining a high-cost base for carriers. Extreme heat disrupts manufacturing and supply chains, burdens logistics, and exposes companies to volatile power prices, driven by the surge in electricity demand for cooling. Without resilient cooling infrastructure and reliable energy supplies, Europe’s industrial transition risks stalling.

Heatwaves are transitioning from temporary disruptions to persistent, systemic economic shocks, demanding a fundamental, long-term strategic re-evaluation of supply chain models. Their economic impacts, including GDP reductions and increased operational costs, are prolonged and intensifying, creating complex interdependencies across sectors like transport, agriculture, energy, and tourism (e.g., low river levels rerouting freight to heat-vulnerable roads). The cumulative effect of infrastructure damage, diminished labor productivity, and elevated operational costs fundamentally alter the logistics economic landscape. This necessitates a proactive, long-term perspective from businesses and policymakers, including comprehensive climate resilience planning, multi-modal transport redundancy, and seasonal inventory buffers. Without such planning, companies face costly reactive decisions like premium transport rates or significant production delays.

Heat’s Toll on Temperature-Sensitive Cargo

Heatwaves, especially during already warm summers, significantly reduce economic activity and agricultural production. In 2025, persistent drought and heat in regions like western Belgium, central France, eastern Germany, Poland, Hungary, eastern Ukraine, Türkiye, Cyprus, and the western Maghreb are severely impacting crop yields, including both spring/summer and winter crops.

The economic implications are clear: ECB research estimates that the extreme summer heat in 2022 contributed to a 0.7 percentage point increase in food prices across Europe, demonstrating a direct link between heatwaves and inflationary pressures on food.

Climate-induced agricultural losses directly translate into inflationary pressures and heightened food security concerns, elevating the efficiency of the cold chain from a mere commercial consideration to a critical societal issue. The significant reductions in agricultural yields for various crops across Europe directly impact the overall supply of fresh produce. This reduction in supply, coupled with consistent or increasing consumer demand, inevitably leads to market scarcity. This scarcity, as demonstrated by the measurable increase in European food prices following heatwaves, is further compounded by the rising operational costs within the logistics sector. The ability of the cold chain to effectively minimize post-harvest losses therefore becomes an even more crucial buffer against these climate-induced supply shocks.

Post-Harvest and In-Transit Spoilage

The total postharvest loss of horticultural crops, which includes both fruits and vegetables, ranges from 15% to 70% across various stages such as harvesting, storage, transportation, distribution and sales. Vegetables alone account for approximately 40% of this loss. This represents a substantial economic burden and contributes significantly to food waste. Poor temperature management throughout the cold chain is a primary driver of fruit quality deterioration and loss.

Adaptation strategies

1. Infrastructure Development

Significant investments are flowing into Europe’s cold chain infrastructure, including advanced refrigerated warehousing, modern transportation systems, and improved port infrastructure. The cold chain sector is rapidly professionalizing, shifting from a fragmented, low-tech industry to a strategic, technologically advanced one. This evolution is largely driven by customer demands for enhanced real-time visibility and greater transparency. Companies offering flexible, tech-enabled services are gaining a crucial competitive advantage. This transformation prioritizes operational agility to build resilience against climate disruptions and secure a stronger market position.

2. Optimized Operations and Route Planning

Leveraging predictive analytics with historical weather, real-time traffic, and precise forecasts is indispensable for logistics. AI-powered algorithms enable dynamic rerouting, helping vehicles avoid congestion, closures, and hazardous weather. This significantly reduces delivery delays, improves ETAs, lowers fuel consumption, and enhances driver safety. To adapt to these demands, some logistics companies are investing in integrated AI-based planning tools. For example, Girteka utilizes the Fleet Operator system — an AI-driven solution developed with Nexogen — to optimize route planning, fuel stops, and breaks dynamically. In case of unexpected delays or closures, the system automatically recalculates the most efficient alternative routes in real time. Paired with Fleet Planner and the Fleet Hand telematics system, this setup also helps reduce empty kilometers and ensures seamless communication between dispatchers and drivers.

“Extreme weather can disrupt road transport in unpredictable ways — from closed tunnels to rerouted traffic or sudden delays. That’s where real-time data and automation become essential. Our Fleet Operator system responds immediately, adjusting routes, fuel stops, and delivery plans in real time. With a fleet of our scale, this kind of AI-driven adaptability helps us maintain performance even when conditions change rapidly.” — Laimonas Čelkys, Head of Transport at Girteka Logistics. To mitigate the impact of heat stress on human capital and product integrity, adapting working hours to cooler parts of the day, including the implementation of night shifts, is a viable strategy for both drivers and warehouse staff. Proactive and rigorous vehicle maintenance is paramount. This includes regular engine servicing, ensuring the use of high-quality coolant, and closely monitoring engine temperature, especially in older truck models prone to overheating.

3. Policy and Regulatory Frameworks

Effective climate adaptation in European road logistics requires robust policy and regulatory frameworks. The EU Adaptation Strategy (2021) and the broader European Green Deal aim for EU climate resilience by 2050, with a key objective of a 90% reduction in transport-related greenhouse gas emissions by mid-century. The Global Cold Chain Alliance (GCCA) urges EU leaders to formally recognize temperature-controlled logistics as critical European infrastructure. This recognition is vital to unlock investment in facilities, vehicles, and specialized skills, enhancing food supply chain resilience. GCCA recommends removing investment barriers, introducing targeted incentives, and strategically expanding existing cold chain infrastructure.

4. Driver Welfare Legislation

There is a growing need for comprehensive policies specifically addressing heat stress for drivers and other logistics personnel. This could involve the implementation of stricter regulations on working conditions during heatwaves.

Adaptation Strategies: Key Recommendations

To build resilience against the escalating threats of heatwaves, strategic, multi-faceted actions are crucial for Europe’s logistics sector. These key recommendations outline a path forward for businesses and policymakers:

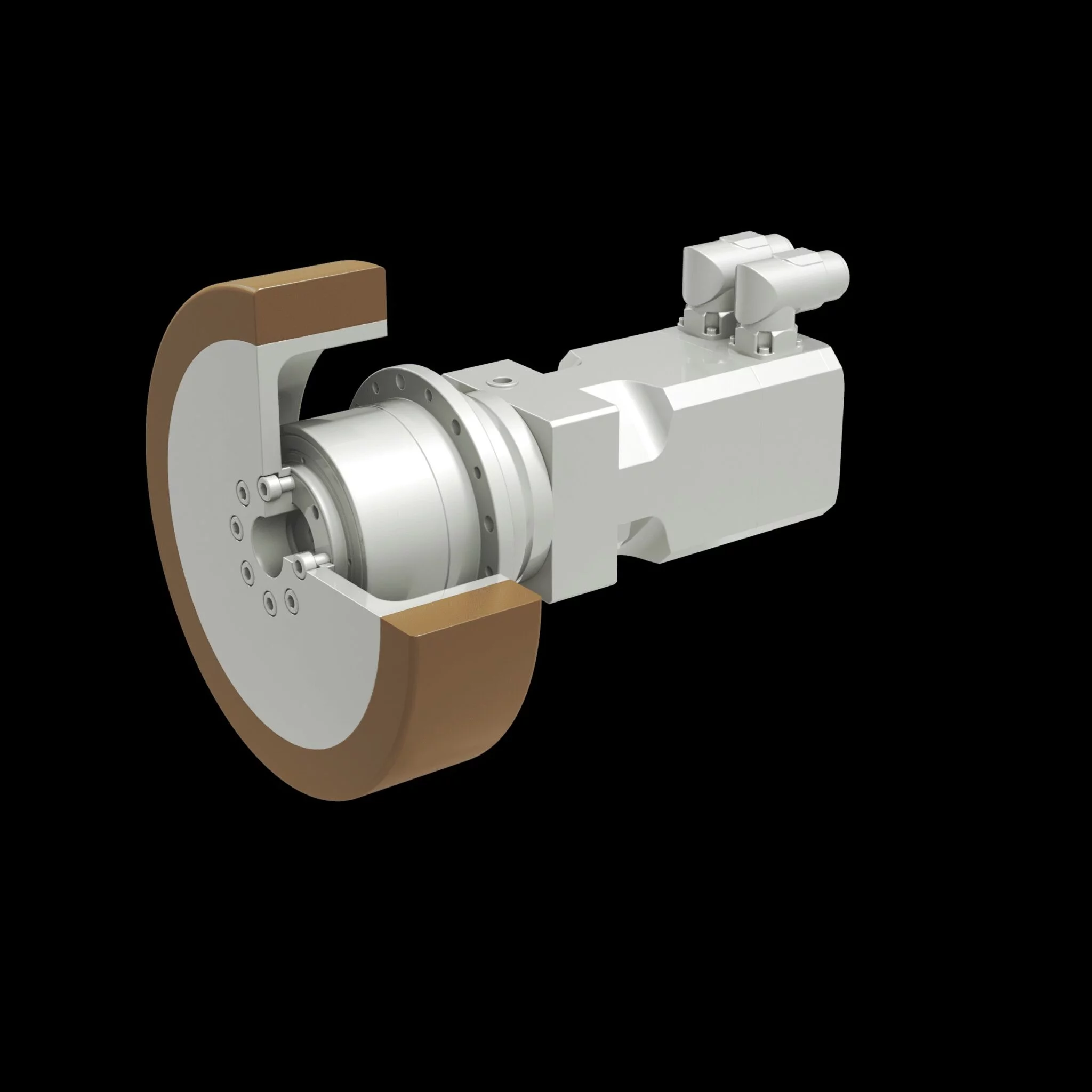

Cold Chain Modernization: Prioritize investment in advanced refrigeration technologies for both warehousing (e.g., automated solutions) and trailers in transit (e.g., self-charging cooling, IoT monitoring).

- This is crucial to boost cold chain efficiency and capacit throughout the entire supply journey.

Infrastructure Climate-Proofing: Accelerate public and private investment in heat-resistant materials and smart infrastructure to ensure transport network durability and continuity.

- Human Capital Resilience: Implement comprehensive heat stress management for drivers and staff, including flexible hours (e.g., night shifts), improved in-cab cooling, and adequate rest facilities.

- Integrated Data & Predictive Analytics: Mandate and support widespread adoption of AI-powered route optimization using real-time weather and traffic data to minimize heat-induced disruptions.

- Holistic EU Cooling Strategy: Develop an EU-level cooling strategy integrating energy security and climate adaptation, setting efficiency standards, and incentivizing clean, reliable cooling solutions.

- Cross-Sectoral Collaboration: Foster strong collaboration among policymakers, logistics, agriculture, and tech sectors to implement systemic, long-term solutions for climate-resilient logistics.

Ultimately, while the road ahead is challenging, a proactive and aligned strategic adaptation is not just crucial but offers the tangible hope for safeguarding Europe’s vital supply chains in an increasingly hotter future.