Clark is presenting the new S-Series Electric to the public for the first time at LogiMAT in Stuttgart. With the SE25-35 electric four-wheel forklift trucks with load capacities of 2.5 to 3.5 tonnes, Clark Europe is launching the first generation of electric forklift trucks that, like their IC engine counterparts, are characterised by the attributes Smart, Strong and Safe.

With their sporty performance, high safety standards and excellent ergonomics, the SE25-35 electric counterbalance trucks keep logistics processes moving, as required by industry, distribution and the food, chemical and pharmaceutical industries, without causing harmful emissions. The electric forklift trucks are designed for high handling performance with low operating costs over their entire life cycle, making them another highly efficient and environmentally friendly alternative to Clark’s IC engine-powered forklift trucks.

Smart – Flexible battery solution with reliable performance

With its advanced smart display with integrated reversing camera, active safety systems and extensive additional equipment, the SE25-35 series is ideal for intensive indoor and outdoor use. A particular highlight are the new lifting masts, which offer excellent mast visibility thanks to the double primary cylinders. In addition to a service-friendly and robust design, many clever ideas for improving operation and ergonomics have been incorporated into the design of the forklift trucks, such as the intuitive direction change integrated into the hydraulic levers or mini levers and the electric parking brake, which prevents the vehicle from unintentionally accelerating or rolling backwards.

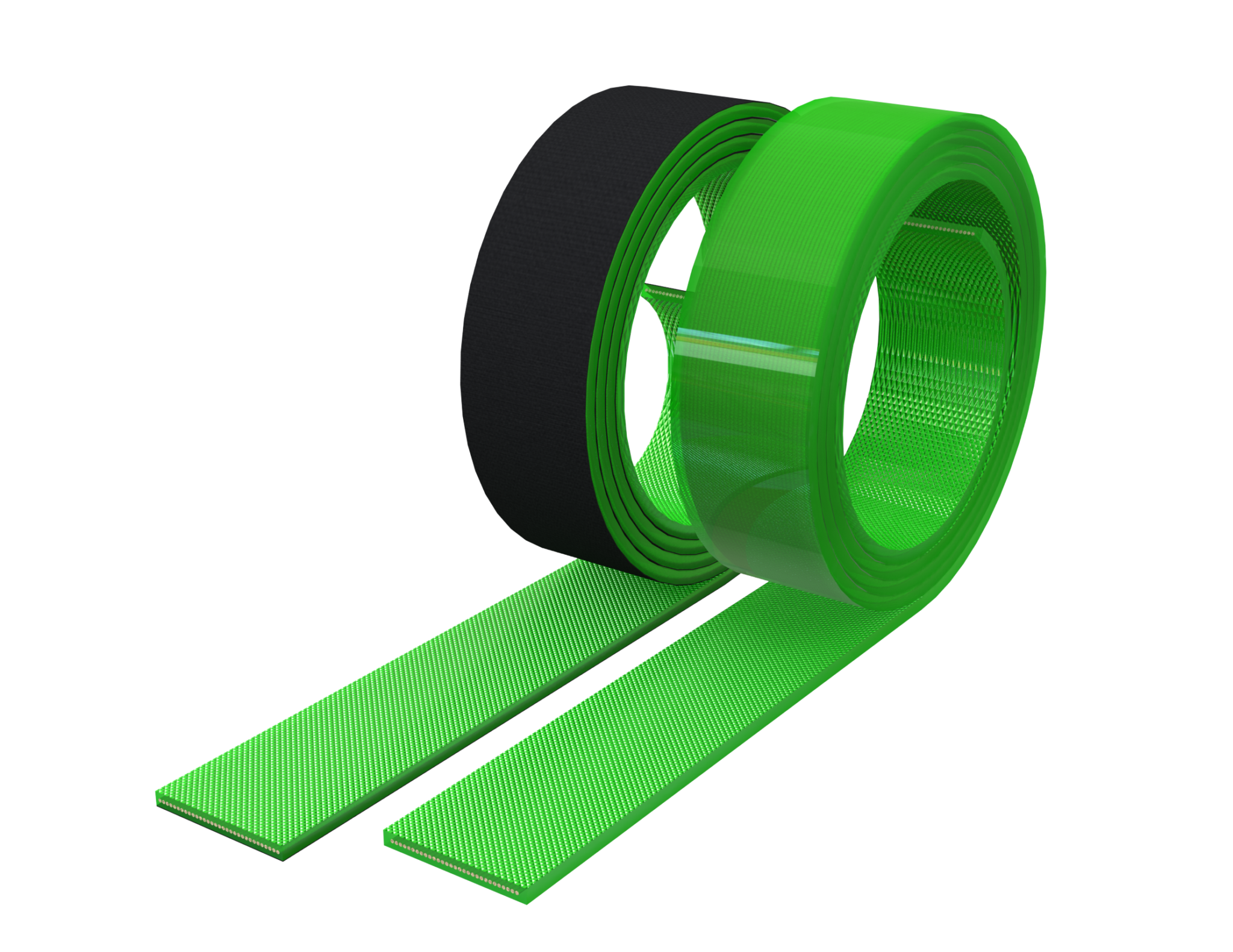

Another highlight: operators have the option of changing the vehicle’s energy source and adapting the software accordingly without any major additional effort if the application requirements change. The operator can operate the forklift truck with the classic lead-acid battery or, if required, switch to the high-performance Clark lithium-ion technology, which is particularly effective in multi-shift applications. Thanks to this smart battery solution, the electric forklift trucks are predestined for almost all applications.

Strong – electric power for peak performance

The models in the SE25-35 series are equipped with two low-noise AC traction motors, each with 9.0 kW and 80-volt three-phase AC technology, which enable rapid acceleration and high thrust. The wear-free, powerful AC motors reach a top speed of up to 19 and 20 km/h respectively. Three individually programmable driving modes are available for energy-efficient utilisation of the truck. Wear-free regenerative braking with the engine brake and automatic speed reduction when cornering can also be set as required. Safe use on sloping terrain or ramps is guaranteed by the automatically engaging electric parking brake. This prevents the truck from unintentionally accelerating or rolling backwards and ensures that the operator always has the vehicle under control.

As you would expect from Clark, the S-Series Electric is also designed according to the Built to Last concept. This requires a solid construction with high-quality and durable components: In the S-Series Electric, this includes wet, maintenance-free multi-disc brakes, a durable and electronically protected gearbox, a stable, vibration-free steering axle, tried and tested lift masts from our own production with 6-roller fork carriage, a solid steering axle and the fully welded frames that are standard at Clark.

The maintenance-free multi-disc brakes with oil cooling, for example, also prove their worth on wet or dusty surfaces thanks to their powerful braking effect. The long maintenance intervals and low operating and maintenance costs should also be emphasised. In the event of maintenance, all relevant components are easily accessible for the service technician, minimising downtimes.

Safe – Ergonomic driver’s workplace guarantees intuitive and safe operation

The S-Series Electric has a spacious and ergonomic driver’s workplace, which provides the operator with generous leg and headroom as well as numerous storage options for documents, drinks, and mobile phones. To meet individual requirements, Clark offers various adjustable comfort seats with air or mechanical suspension. The tilt of the steering column can be adjusted to suit the operator. The pedals are automotive-compliant. The operator has an excellent forward view of the forks and the load. This is ensured by the generous viewing window and the nested mast profiles. These increase safety when travelling straight ahead and when storing and retrieving loads. In triplex masts, the free lift cylinders are designed as double primary cylinders, which also provide the best forward visibility. The high-contrast, splash-proof 5-inch colour display provides information on all important vehicle parameters, such as travel speed, load weight and operating time until the next service. Safety and warning messages are displayed in 24 languages. When using a reversing camera, the image is transmitted to the colour display so that the operator has a good overview of the activities on his route when reversing.

The vehicle can be operated either via adjustable mini levers integrated into the armrest or via ergonomically arranged hydraulic levers on the vehicle bonnet. The intuitive switching of the direction of travel on the hydraulic or mini-lever takes the strain off the driver, as he does not have to reach round to switch. The power steering ensures that only low steering forces and few steering wheel turns are required when manoeuvring. With a steering angle of 101° (Zero Steer Turn Axle), the vehicle turns almost on the spot and is ideal for use in narrow aisles. The SE30s is, in particular characterised by uncompromising manoeuvrability. In this model, Clark combines the compact frame of the 2.5 tonne model with a higher load capacity of three tonnes and the powerful twin-engine front-wheel drive. This makes the SE30s ideal for handling heavy loads in extremely space-critical work areas.

For extra safety

For operators who prioritise maximum safety, additional safety features are available as an option. These include, for example, the load weight indicator, which measures the weight of the load on the forks and helps to prevent the truck from being overloaded. With the Vertical Mast System (VMS), which is also optional, a tilt sensor automatically brings the mast into a vertical position so that goods can be loaded and unloaded quickly and safely. The VMS positions the mast vertically both when tilting forwards and backwards and equalises the vehicle position on uneven floors or ramps.

New Clark SafeView HD camera system

With the S-Series Electric, Clark is also launching the new optional SafeView HD camera, which is intended to replace the analogue SafeView camera system. The SafeView HD is a completely digital HD camera with 1280 x 720 pixels (16:9) and with three wide-angle cameras (left/rear/right) installed on the forklift as well as a 10-inch touchscreen. The operator can choose between different views as required (bird’s eye view, split screen view and 3D view). This significantly increases safety during use, as the operator always knows what is happening in their working environment in real time with a frame rate of 30 fps.

Customised for the application

Clark offers extensive additional equipment and options for different applications for the S-Series Electric: The optional equipment includes different cabs, such as rain protection (steel roof), weather protection (steel roof and windscreen), partial (steel roof, front and rear windscreen) and full cabs, mini levers integrated in the armrest with direction of travel change or mechanical levers, side battery change by hand pallet truck, blue LED warning lights as visual reversing warning, load weight indicator, USB charging port for charging mobile devices, attachments and additional safety options.

read more

Clark Debuts ‘Smart, Strong and Safe’ IC Forklift