As retailers face mounting pressures to meet ambitious environmental, social, and governance (ESG) targets while balancing costs and profitability, Ben Whitby, UK Operation Director at Staci UK raises a pressing question: can Black Friday – one of retail’s most significant contributors to the environment – ever be genuinely sustainable.

Black Friday 2023 saw record-breaking numbers in the UK, with retailers generating £13.3 billion in sales and engaging 53% of consumers. Yet, not all records are cause for celebration. The event also reached unprecedented levels of environmental impact, with deliveries alone estimated to have generated 429,000 metric tonnes of greenhouse gas emissions, the equivalent of 435 round-trip flights between London and New York.

The data makes for grim reading, and with over half of consumers voicing concerns over Black Friday’s environmental costs, is it time to reimagine this shopping phenomenon through a green tinted lens? And what steps can brands take to make sure peak-season operations don’t impact long-term ESG objectives?

“To put it bluntly, unless we find more sustainable ways of delivering fulfilment for eCommerce, retailers simply don’t stand a chance of meeting environmental goals, while still delivering on customer demands.” That’s the view of Ben Whitby, Staci UK’s operations director, who is working with retail partners to “minimise retailers’ impact on the planet” while keeping up with their customers’ needs in a fast-evolving digital world.

Ahead of the return of the UK’s biggest shopping event for 2024, he delves into the strategies of the retailers making tangible progress and offers his expert insights into how others can strike the perfect balance between sustainability and profitability.

1. Perfecting packaging processes

With advances in eco-friendly materials, tech-enabled design, and optimised supply chain strategies, retailers now have more sustainable options than ever to package their products responsibly. But the expertise of a specialist partner can help take that to the next level. Whitby highlights the importance of a “collaborative, adaptable approach” in helping brands align their packaging processes with ambitious environmental goals; “Packaging presents one of the most immediate opportunities to cut carbon emissions,” he explains. “While a full overhaul may not be feasible for every item, especially given the surge in deliveries during events like Black Friday, retailers can make smart choices about shipping methods to improve efficiency, reduce waste, and limit emissions.”

Whitby claims that by analysing key metrics such as average order volumes, item turnover rates, and raw material usage, retailers can find ways to optimise their packaging. “Reducing not only the quantity but also the size of boxes, or shifting smaller items to letterbox-friendly packaging for smaller items, can lead to fewer delivery vehicles needed per order. This, in turn, lowers road mileage and significantly reduces associated emissions,” he adds.

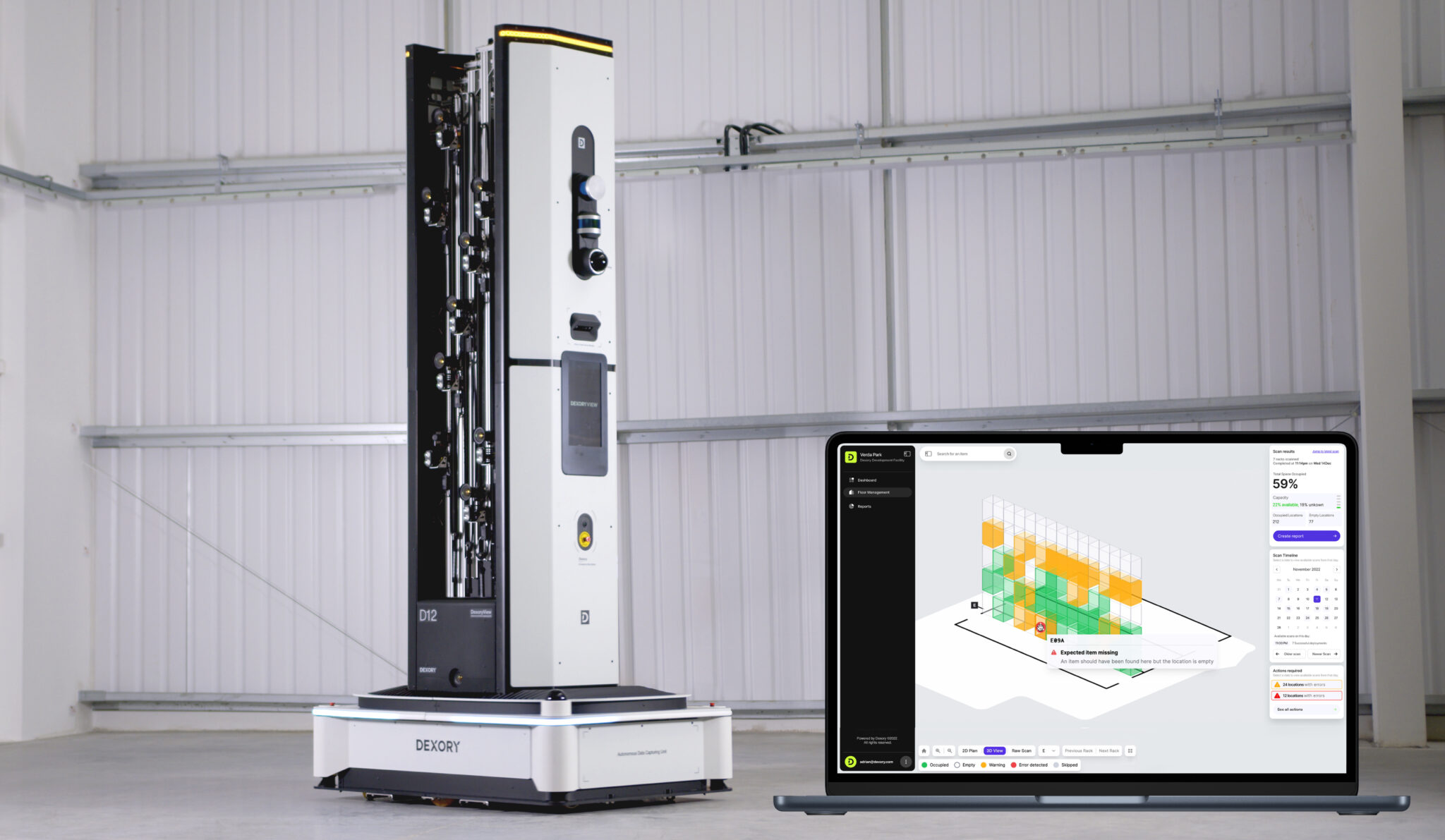

2. Reducing warehouse-based emissions

Online retail warehouse occupation has surged by 813% over the past decade, growing from as little as 8 million sq ft to 69 million sq ft in the UK alone since 2015.

“The growth of warehouses and distribution centres comes as no surprise given their importance in today’s retail landscape,” says Whitby. “However, the rapid expansion of online shopping has significantly impacted the size and operational demands of these facilities, resulting in higher energy consumption and environmental impacts. From inefficient lighting, heating, and cooling to suboptimal fulfilment processes, these warehouses can be a major source of Scope 2 emissions.”

It’s a no-brainer that retailers tackle “unbridled” energy wastage, waste reduction, and greener delivery methods, and each should be a key part of any brand’s sustainability strategy. He adds: “By considering switching to renewable electricity, implementing more efficient inventory and warehouse management, sustainable returns management, and even implementing recycling and waste management programmes, brands can make significant strides in reducing emissions and achieving Net Zero goals.”

3. Considering greener Black Friday deliveries

Online shopping during Black Friday causes a significant spike in carbon emissions, with delivery trucks releasing 94% more CO2 than during a typical week. This surge is driven not only by the demand for next-day delivery – often resulting in half-filled trucks – but also by the shift from what was once a single day of frantic bargain hunting to a multi-day, and in some cases weeks-long, shopping frenzy. As a result, the environmental impact grows with each passing day.

Whitby says that this, paired with the rise of the “eco-conscious consumer” is pushing brands to rethink how they fulfil the surge in orders during Black Friday and Cyber Monday. Recent studies show that 37% of retailers report a noticeable shift: consumers are increasingly mindful of their environmental impact when deciding how much to buy, with 32% even reducing the volume of items they order out of concern for sustainability.

“The growing shift toward environmentally-conscious shopping is certainly a challenge for retailers looking to maximise profits, yet it also offers a real chance to connect with customers who care about sustainability,” says Whitby. “As shoppers become more intentional in their purchasing habits, many retailers are recognising an opportunity to build lasting loyalty and set themselves up for long-term success by adopting practices that reflect these changing values.

“Fully electric or hybrid vehicles are one of the most effective ways to reduce carbon emissions, while for short distances and urban deliveries, pedal powered cargo bikes or e-scooters offer zero-emission solutions that are agile in traffic and suitable for congested city areas,” says Whitby. “While not all vehicles can be immediately replaced by electric alternatives – especially when considering factors like payload, capacity, and range for logistics fleets – retailers should consider scaling their transition to greener transportation options.”

Supply chain sustainability progress requires all stakeholders to be brought into the journey, not just retailers, but also their 3pl logistics partners, warehouse operations, and more.

similar news