Escalating costs and continued demand for warehouse space are placing ever greater pressure on organisations to optimise existing warehouse efficiency by track and trace. Yet with warehouse operatives still hard to recruit, how can existing staff achieve the levels of pick and pack accuracy, and speed, required to meet deadlines without compromising the overarching precision needed, that underpins a great customer experience?

In a pressurised environment, it is often hard to ensure robust processes are always followed. If parcel labels are inadvertently damaged by overstretched staff rushing to load pallets, barcodes cannot be read and deliveries fail. A lack of resources and a need to prioritise pick and pack can lead to physical stock takes being repeatedly postponed, undermining the accuracy of inventory information. Pressure to hit quotas can lead to packaging and label liners being discarded on the floor at times, creating serious health and safety risks which undermine the workforce experience, adding to the risk of staff loss.

With warehouse improvement now a priority, Jay Kim, Managing Director, BIXOLON Europe GmbH explains how innovations in labelling technologies, including linerless and RFID labels, are transforming cost, efficiency and safety throughout warehouses, while also delivering additional sustainability benefits.

Cost of Failed Delivery

For many organisations throughout the manufacturing, logistics and ecommerce sectors, the quality of the delivery experience has become a serious concern in recent years. From delays due to supply chain glitches and Post Office strikes, to inconsistent performance from couriers, missed or late deliveries can add significant cost to any business.

The problems are not, however, solely due to failures of third-party delivery organisations. How many parcels fail to reach the customer in the first place due to damaged labels? Barcodes are easily damaged, by weather and scratches, and if a barcode cannot be read at any stage of the fulfilment process, the implications on the business can be very significant.

From the demands on customer service, to the difficulty associated with getting the product back into the supply chain and sending a replacement, and the impact on customer perception, a single damaged barcode can have a cost that far exceeds the value of the product. For ecommerce providers, the cost is even greater, with almost two thirds (63%) of frequent shoppers in the UK abandoning an online retailer over a poor delivery experience. This is also true for 53% of French and 38% of German customers.

Robust Labelling

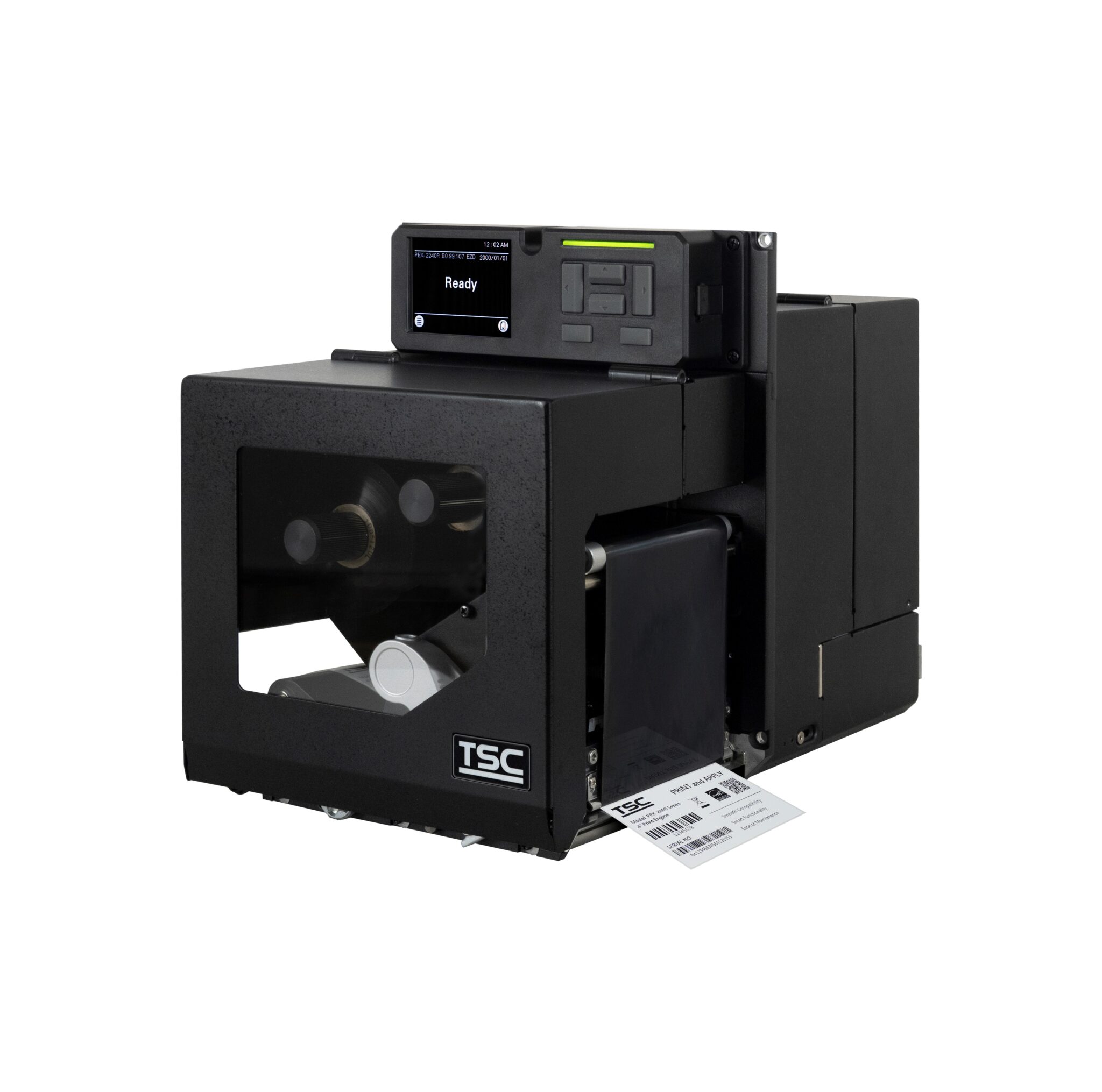

Better quality printer and labelling technology is reducing the risk of barcode damage associated with traditional thermal direct printing. New generation linerless printers, ensure the barcode is protected from damage due to heat, sunlight, rain water and scratches at every stage of the journey. Increasing label resilience can significantly improve delivery timeliness and experience across the customer base, reducing the impact on customer service and eradicating the cost of providing replacement products.

One of the additional benefits of linerless labels is their flexibility. Rather than the constraint of specific label size, linerless labels can be cut to length. This allows the warehouse to include all the pertinent information on one label, rather than requiring one for a barcode, one for country specific safety information and so on. Indeed, the ability to include all information on one label removes the need for multiple printers within the packing department, allowing further streamlining of warehouse operations to drive additional efficiency.

Furthermore, by eradicating the plastic label backing, these linerless labels also deliver a number of additional benefits, not least compliance with the EU directive on packing and packaging waste. With no plastic liner to dispose of, warehouses automatically reduce costs and enhance their sustainability credentials. Indeed, each roll of linerless labels includes 40%-50% more label in the same space, reducing the weight, volume and hence carbon dioxide emissions during transport. Plus, with each label cut to the size required, there is no waste.

Improving Information

Of course, barcodes are not the solution for all inventory – in many cases, items are too large, heavy or unwieldy to allow staff the line of sight required for the optical barcode scanning. Radio Frequency Identification (RFID) has become a valuable tool for these goods, enabling traceability without requiring line of sight. Adding dedicated RFID printers to the warehouse environment transforms the accessibility of RFID technology by allowing companies to include all the information upon a trackable label.

Adding RFID transforms the efficiency of inventory control. With no need for line of sight, the entire process can be swiftly and accurately completed with minimal manual effort. Given the on-going lack of available skilled warehouse staff, and their rising costs, the ability to allocate valuable staff to urgent pick and pack tasks without compromising inventory accuracy is compelling.

Furthermore, with the rise in theft across the supply chain, the ability to efficiently add RFID labelling to the warehouse processes is becoming increasingly attractive, especially in areas such as sports clothing, that are prone to high levels of product theft. Any attempt to remove RFID-tagged goods immediately raises an alert to security staff, allowing companies to both intervene when theft occurs and create an active deterrent to potential thieves.

There is one final, and important, benefit offered by linerless labels – better worker health and safety. With recruitment and retention of staff a continued challenge, warehouse managers need to ensure every aspect of the environment is safe. Label liners can be slip hazards for both people and forklifts, especially when warehouse staff are under time pressure. Swapping to linerless technology removes the dangerous swathes of label liners on the warehouse floor, immediately improving health and safety and improving the working environment.

Furthermore, this technology is both accessible and affordable. Linerless and RFID printers have been available for some time but, to date, have been adopted by approximately 10% of warehouses – in part due to the higher prices of linerless labels when first introduced. With linerless label prices now on a par with traditional labels, the business case is now compelling. Whether the primary concern is delivery performance, inventory control, creating a safer environment, improving green credentials, or all of the above, making the change to innovative printing offers significant opportunities to address a number of operational challenges throughout a warehouse operation.