Mujin, a global supplier of intelligent robotic automation, today announced the opening of its first European office, strategically located in the Netherlands. This expansion follows a series of transformative achievements, including significant funding, global expansion, and growing market adoption.

Mujin’s new European headquarters, situated in Eindhoven, represents a pivotal step in the company’s commitment to global expansion, driven by an $85 million Series C funding round. The funding aims to position Mujin as a significant player in delivering cutting-edge automation solutions to a broader international audience.

The Netherlands, renowned for its innovation and logistics excellence, provides the ideal home for Mujin’s European base. This European office will serve as a central hub for sales, customer support, and solution development, enhancing Mujin’s ability to meet the unique needs of European businesses across various industries.

“We are very excited to enter new markets in Europe,” said Lukasz Drewnowski, CEO at Mujin Europe. “We already have many partners in Europe for whom our close presence will certainly make collaboration even easier. The European market is very mature and customers expect very high standards. We feel that Mujin is a perfect fit to meet these requirements and will become the number one choice for local customers.”

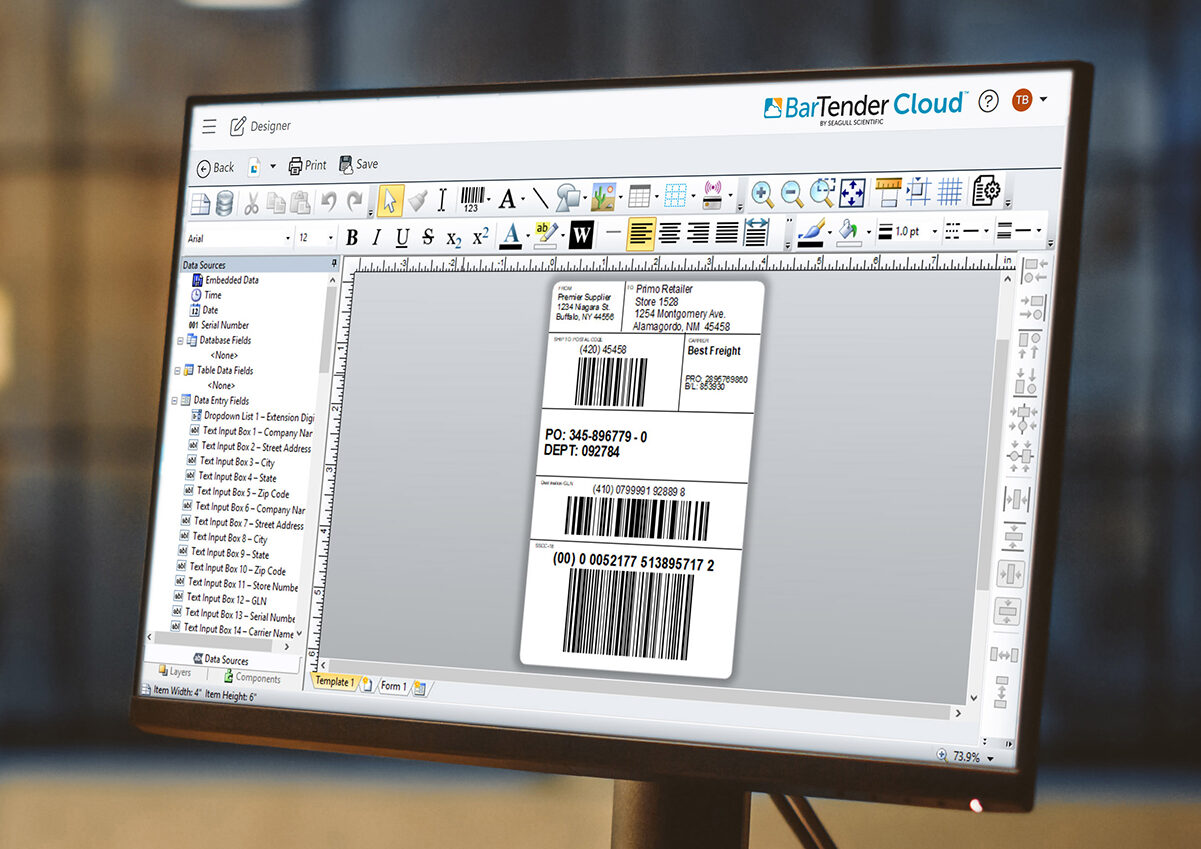

Mujin’s advanced robotic solutions, including TruckBot, Random Palletizing, Depalletizing, and Bin Picking, have already been met with enthusiasm in the European market, where the need for intelligent automation is on the rise.

“We’re thrilled that the European market can start to get a taste of intelligent robotics with MujinController,” said Ross Diankov, CEO of Mujin Corp. in the U.S. “There are so many features and capability packed into the platform that it will help unlock a lot of next-generation applications in the warehouse and manufacturing sectors across Europe.”

Mujin is actively expanding its European team, currently recruiting salespeople and engineers to support the new office’s operations and meet the demands of the European market. The European operations will be led by Drewnowski, who brings a wealth of experience to the role. Prior to joining Mujin, Drewnowski served as business manager, operations manager, and managing director at ABB Robotics in Poland, China and the UK.

Mujin’s global presence also includes offices in Tokyo, Atlanta and Guangzhou.