Exhibitors from nearly every sector of the industry are coming to LogiMAT 2024 to present their latest products and solutions for ergonomically optimized intralogistics processes, healthy workplaces, and injury prevention. The spectrum ranges from modular workstation designs and systems to hoists not yet exhibited anywhere in the world, software-driven language-based picking processes with smart glasses, and new accessories and assistance systems for forklift operators. An Expert Forum taking place during LogiMAT presents tools and solutions for the ergonomic design of workstations and processes.

The intralogistics industry has not been spared the ravaging effects of demographic change and labor shortages. Some 100,000 logistics-related jobs in Germany alone remain unfilled. This makes ergonomics a topic of growing importance for businesses. Higher-quality workstations, improvements in how physical activities are performed, smart workstations designed with the help of digital technology, human-robot collaboration, and devices to ease the physical strain on workers: These are just some of the tools that can make workflows more efficient and the field of intralogistics more attractive. To cite just one example, a study published in late 2023 on the introduction of wearable exoskeletons found that they could reduce muscle strain in workers with the most strenuous jobs by up to 30 percent. Accuracy rose 27 percent, and speed was up 10 percent. Workplace safety improved while illness-related absences fell. “Ergonomics is an important element of intralogistics. Ergonomic workstations ensure the future of intralogistics and make it easier for the industry to compete for talent,” explains Exhibition Director Michael Ruchty from event organizer EUROEXPO Messe- und Kongress-GmbH in Munich. “LogiMAT, in its role as a barometer for intralogistics industry trends, is the primary platform for presenting the latest developments in this sphere. That’s why we’ve embraced this topic as one of the three areas of focus at this year’s event, as captured in our theme ‘SHAPING CHANGE TOGETHER: Sustainability – AI – Ergonomics.’”

Veronika Kretschmer, Senior Scientist for Assistance Systems and Human-Technology Interaction at the Fraunhofer Institute for Material Flow and Logistics IML, highlights possible solutions for ergonomically realigning workstations and workflows in her Expert Forum in the East Entrance Atrium, taking place on the second day of LogiMAT 2024. The forum’s content is aligned with Fraunhofer IML’s “Social Networked Industry”—a vision for the workplace of tomorrow in which people and new technologies work together collaboratively in an atmosphere of safety and trust. The tools introduced to support this vision range from exoskeletons and pick-by systems providing cognitive support for pickers to AI-based analytics of movement data for the optimization of intralogistics processes.

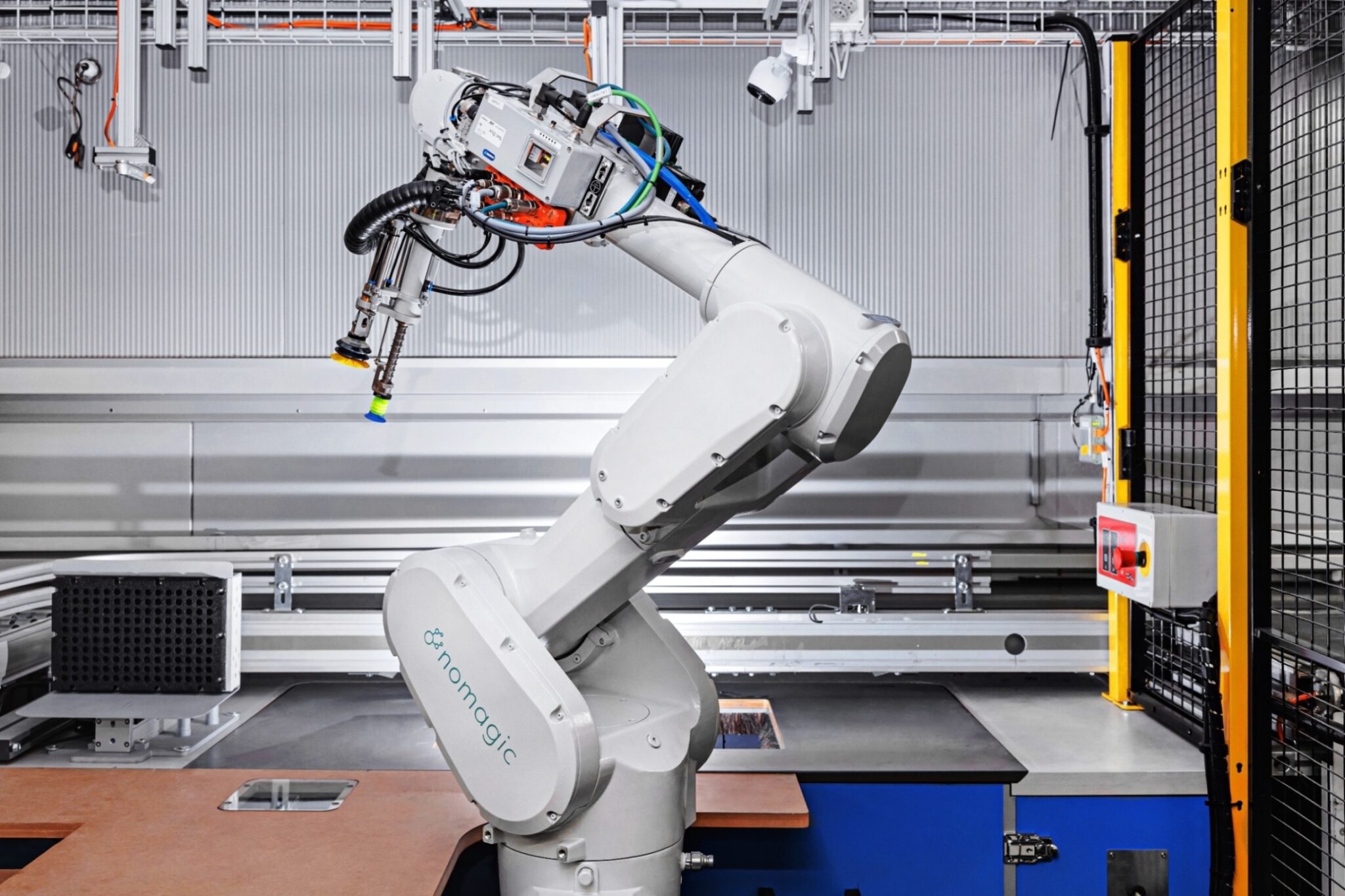

Human-machine collaborative workstation

Exhibitors from every sector of the intralogistics industry are also coming to LogiMAT in Stuttgart, March 19–21, to showcase their latest innovations for reducing physical strain and ergonomically optimizing how workstations are designed and equipped. Systems integrators and industrial machinery and equipment manufacturers in Halls 1, 3, 5, and 7 will exhibit new products for the ergonomically optimized design of picking and sorting stations, such as those used in AutoStore systems. The theme greets visitors as soon as they arrive through the East Entrance with the design for a manual picking and packing workstation, presented in the live demonstration of an assembly line innovation that includes custom packing tables and a centralized robotics system that supplies material and removes empty containers.

Exhibitors in Halls 4 and 5 are presenting various new workstation systems for modern assembly, logistics, and warehouse operations. Optimized ergonomics, flexibility, functionality, and a customized modular concept are the hallmarks here. This makes it possible to easily adapt individual components such as shelves, holders, packing tables, and worktables to different body sizes and processes, and to implement upgrades and extensions or integrate new digital technologies at any time. The result is ergonomically efficient systems for logistics jobs with long-term viability. New automated packaging solutions offer customized packing processes that optimize the use of resources and reduce the number of tasks that still need to be performed manually.

The world’s first fully mobile manipulator

Hall 7 will give visitors the opportunity to test new products never yet exhibited anywhere in the world, innovative wire rope hoist and workstation crane systems, and new modular lifting devices for ergonomic, easy, effortless handling. The modular concept lets workers configure their mobile or stationary industrial lifting equipment to match their individual needs. The assistance systems for simplified manual load handling on display in Hall 7 will also include innovative new suction grippers for cardboard packaging and bags. Visitors should also keep an eye open for the world’s first fully mobile manipulator for handling cartons, crates, packages, and containers.

For the manufacturers of industrial trucks and attachments in Halls 9 and 10, ergonomics is focused primarily on providing a comfortable workstation for forklift operators and easy-to-use, multifunctional attachments. Visitors to LogiMAT can look forward to experiencing innovations in equipment and assistance systems. One example is the first-in-Europe live demo of a combination package for forklifts with both location- and event-related features designed to automatically identify and avoid any dangers to people, vehicles, or loads—for enhanced safety and a more comfortable ride. New concepts for improved human-machine interaction and machine learning in the use of autonomous devices will also be presented. A new eurobin tug on display in Hall 9 is an ergonomic lifting and transport solution that gives workers a powered boost in moving eurobins weighing up to 300 kg in an optimal, upright working position, significantly reducing physical strain.

Vision picking for the digital warehouse

Many of the software developers in Hall 8 are showcasing new features and applications in their systems that reflect the role IT solutions can play in the ergonomic planning and design of facility layouts and workflows. A vision picking solution featuring smart glasses illustrates how the integration of cutting-edge technology in ergonomically optimized workflows can support digital warehouse logistics.

Next door in Hall 6, visitors can experience the latest innovations for collaborative workflows in the human-machine interface with automated guided vehicle systems and all the latest robotic solutions: cobots, stationary industrial robots, mobile picking robots, and autonomous mobile robot transport systems. The focus here is on sensor-based safety and ergonomic workstation design at transfer points and the periphery of the line, for example. Sensor technology and convenient identification solutions are also a defining feature in the new products and solutions presented by the specialists for automatic identification and data capture (AIDC), concentrated this year in Hall 2. Smart labels whose data can be read and modified by stationary and mobile readers, and cloud apps with automated interfaces and features for direct printing: These are just a couple examples of how AIDC solutions cut down on walking distances and make life easier for warehouse workers.

“Ergonomics in intralogistics helps maintain worker health and prevent injuries and excess physical strain, ensuring the continuity and efficiency of intralogistics processes,” Ruchty concludes. “Exhibitors at LogiMAT 2024 are presenting a wide range of state-of-the-art solutions for ergonomically optimized workstations. Integrating this cutting-edge technology improves working conditions in the intralogistics industry, and this can enhance the image of logistics-related careers.”