A division of Ambrosi S.r.l., ONO Lean Logistics has partnered with the METALSISTEM Group. ONO Logistics was established to design and develop Scalable Automated Warehouse Systems. These solutions mesh perfectly with METALSISTEM’s wide range of pallet racking, shelving and shopfitting systems as well as its automation and material handling solutions. The capital investment of the METALSISTEM Group into Ambrosi S.r.l. will form an alliance that will further expand the scope of the METALSISTEM product range into the field of intralogistics.

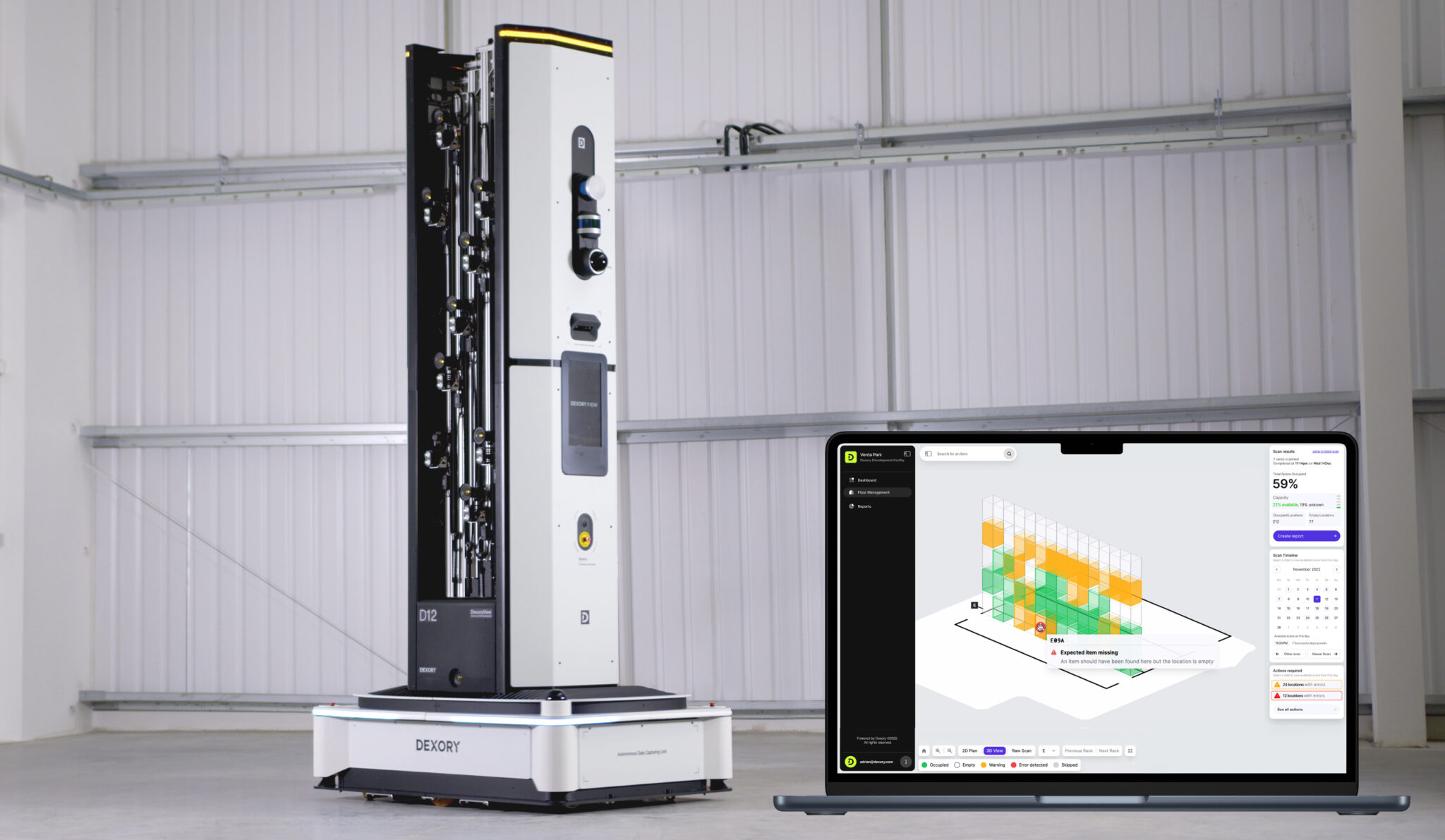

Advancements in process automation has brought about an unprecedented evolution in the way industry approaches the management of goods: the union of ONO Lean Logistics and METALSISTEM provides a response to this trend by advancing the market penetration on both companies within the field of intralogistics. ONO Lean Logistics, founded in 2016, has been steadily growing by strengthening its hardware and software presence with installations successfully completed for top tier companies in various sectors. The ONO Scalable Automated Warehouse System has effectively pioneered a new market segment by providing an intelligent and efficient solution applicable within both logistical and production settings.

With its main production facilities and Headquarters based in Rovereto (TN) – Italy, the METALSISTEM Group is made up of a diverse network of companies of which ONO Lean Logistics, through Ambrosi Srl, are proud to be a part of. The unmatched production capacity and extensive sales network place METALSISTEM among the global leaders of the Material Handling sector.

METALSISTEM has partnered with Ambrosi S.r.l. to strengthen its influence within the material handling sector by offering an innovative solution with a strong focus on the development of advanced technologies, including automated modular warehouse systems as well as dedicated software.

The collaboration between ONO Lean Logistics and METALSISTEM was officially announced in July 2023 following a long consultation period during which the convergence of visions and objectives was confirmed. “The alliance between these two companies, one a consolidated market leader, the other rapidly ascending, reflects a vision of innovation powered by young talent, ready to explore and recast an entirely new sector,” says Thomas AMBROSI, CEO of Ambrosi S.r.l. “With ONO Lean Logistics, we have created a new market segment for production processes and intralogistics. This collaboration will undoubtably open new doors and METALSISTEM’s technological contribution will further enhance the approach to our product in every aspect by leveraging the synergies that exist between our respective research and development departments”.

Mirco BRIOSI, General Manager of METALSISTEM S.p.A., added: “The union of these companies creates an opportunity to expand automated projects, with a foothold in modular systems for intralogistics and moving, with enthusiasm, towards future developments in integrated automation. Furthermore, we cannot underestimate the contribution of software towards this objective, as this is a key entry point into the global market. When faced with a challenge, in the material handling sector, there are always multiple solutions capable of providing an adequate response, although none of them may be optimal, all may be improved upon. Through our combined strengths, METALSISTEM sees an opportunity to offer the market a highly innovative product which is unparalleled in this

sector. It will integrate by leveraging diverse solutions within the same system thus bringing together the strengths of multiple technologies. In addition, the flexible and modular nature of the ONO Lean Logistics products have proven to be perfectly compatible with the METALSISTEM philosophy that has been applied to its product for over 50 years and which, like a ‘Lego set’, is encapsulated in its slogan ‘Customised Modularity’.”

The alliance between ONO Lean Logistics and METALSISTEM promises to bring simplification, efficiency, and continuous innovation to the intralogistics sector with a particular focus on sustainability. This partnership will significantly contribute to the growth and development of advanced solutions for this evolving market.