Past mistakes should inform, but not inhibit, the adoption of new technologies within the food supply chain. Dan Migliozzi, Sales & Marketing Director, at independent systems integrator, Invar Group, explains why the sector needs to rediscover its appetite for risk.

The food and grocery market in the UK is one of the most competitive and fast-moving retail sectors, arguably, in the world. The pressures are immense, with disruptors to existing business models ranging from the rise of the discounters and the explosion in home delivery to the impact on supply chains of everything from weather to war. In addition, there is the constant cycle of new products and trends, such as vegan/meat free, which may or may not become established.

And all this is set against the challenges of ever more costly and increasingly unavailable labour, uncertain but generally increasing transport costs, and a consumer base that despite, or because of, the ‘cost of living crisis’, demands convenience and availability at the lowest price and exhibits diminishing levels of loyalty to retailers and brands.

To meet these challenges, one might think that investment in automation in the fulfilment chain – warehouses and distribution centres – would be a no-brainer. Higher throughputs, managed, picked and delivered more accurately, improving service levels with less inventory (and waste), better transport utilisation, all with lower levels of labour and a more flexible and agile response to changing market conditions, whether there be one-off events or longer-term trends.

Past mistakes

Yet, there is a clear reluctance amongst supermarkets and other food businesses to go all-in on automation. This is perhaps unsurprising – there are few of the well-known names that haven’t experienced some sort of technology-driven crisis over the past decade or two. Not infrequently these have left the business section for the front page, leading not just to missed sales and unhappy consumers, but to panicked shareholders, questions in Parliament, and ‘thoughtful’ op-ed pieces in the media. More often than not, the ‘solution’ has been to side-line the tech and flood the warehouse with people.

As a fully independent automation and systems vendor and integrator, however, we observe that it is only rarely that there have been fundamental issues with the hardware and software. Rather, the issues lie around timescales, complexity and over-ambition, and a lack of forward vision. Major investment decisions appear to have been driven by a combination of FOMO – fear of missing out on what the competition is thought to be doing, and the understandable desire of owners, whether public shareholders or private finance, to ‘sweat the assets’. Neither of these are sound foundations for the serious investment in advanced technologies that the sector undoubtedly needs.

Paradoxically for such a fast-moving environment, our first piece of advice would be to slow down a bit. Take the time to think ahead. However fast the implementation of technology, it may well not outpace transformations in the industry: think how quickly home delivery moved from being a niche ‘inside the M25’ offer to being core business in the Highlands and Islands!

A measured approach

Implementation doesn’t have to be simultaneous and company-wide, across half a dozen DCs. Starting with a large-scale pilot across a single DC, a particular class or skus and/or a particular channel will allow you to find out, not just if the chosen automation is really appropriate, but more fundamentally, whether you have truly captured the reality of how your business works, or should work, in practice.

This may mean that some of the potential efficiencies and savings are not immediately captured, but these are by definition long term projects. If this scale of investment is really the answer to today’s problems, there are probably deeper issues at play. The business needs to look out as far as it can, with the best forecasts (or range of forecasts) available. This automation is supposed to make the company more successful – so what does ‘success’ look like, not next quarter but in five years’ time?

Change is the only certainty – how flexible, adaptable, scalable is the solution you are proposing? Do you need a higher level of ‘robotics’, broadly defined, to meet a largely unknown future, or is it appropriate (as it may be), simply to opt for significantly over-specified fixed automation? But while any level of investment must meet a business case, it is a false, and potentially disastrous, economy to allow this apparently unnecessary surplus capability to be stripped out of the proposal. Could it, in fact, be unnecessary? Has anyone mentioned promotions?

Examine flexible options

There is a lot of detailed ‘what if?’ thinking to be done – what if, for example, demands for less packaging lead to more loose goods being handled? That might steer the project towards a greater use of robotics for item-level manipulation, rather than fixed automation at a carton or pallet level. There are also assumptions to be challenged – it may be that the automation plan expects suppliers to deliver in a certain manner. Actually, they don’t but that’s alright because the workforce knows the work round. The automation probably doesn’t. The automation has to be designed around the supply realities, but equally the suppliers have to be aligned with the automation.

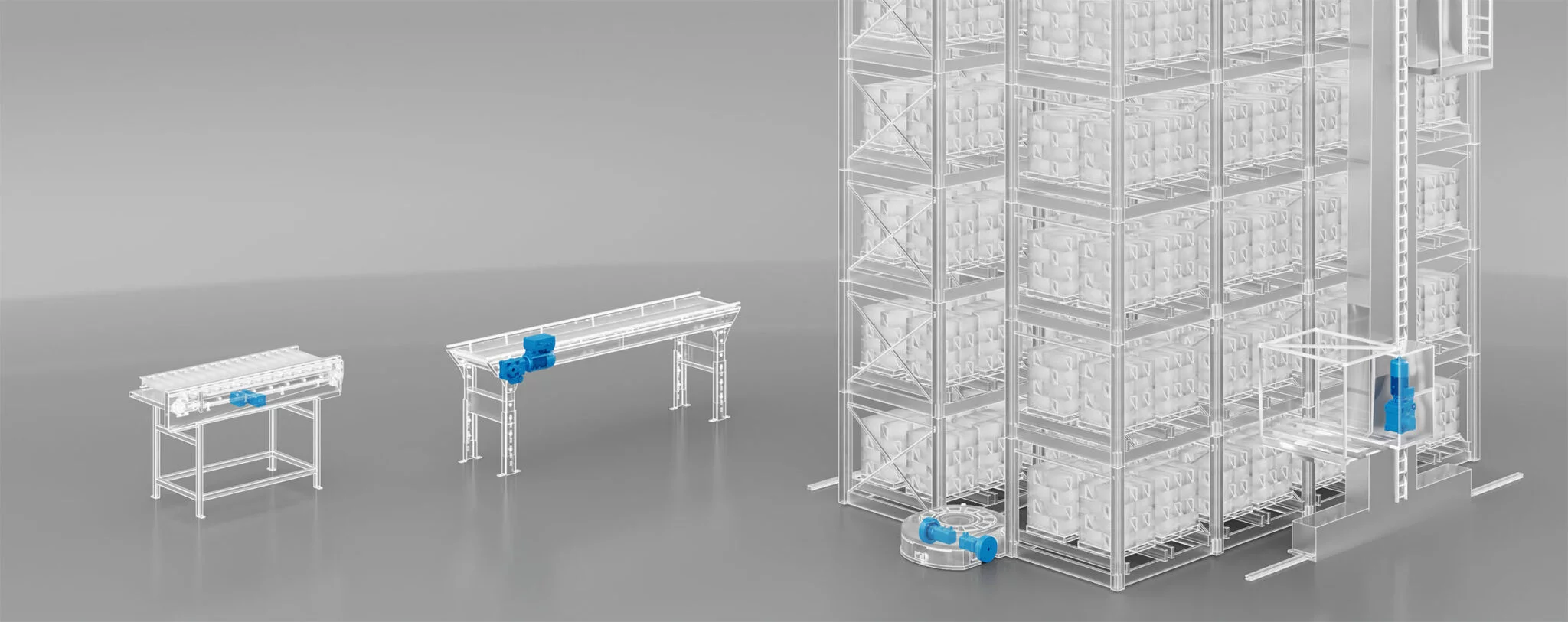

And although we stress the need for the longest-term planning, it does have to be accepted by the business owners that it may be desirable to replace at least some elements of the automation years before its theoretical end of life. Fixed automation, or AS/RS (automated storage and retrieval systems) may be a valuable interim solution to be augmented or replaced a few years down the line by AMRs (autonomous mobile robots), ‘cobots’ working alongside staff, or whatever else technical progress brings forward. AMRs, incidentally, are a great way of achieving great scalability for low CapEx, as units can be taken on or off lease as requirements vary – easier and cheaper than hiring a hundred extra bodies.

An appetite for risk

The food chain is always under huge pressure – consumers, media, shareholders, suppliers, and often with an added political element. To meet these pressures, the food distribution chain needs to rediscover its appetite for risk. But don’t panic – by working with an independent and experienced systems integrator such as Invar, those risks can be well-controlled.

Read more…

80% say Brexit is biggest disruption