Automated trailer loading systems (ATLS) are often considered the domain of large-scale manufacturing facilities and distribution centres operating shuttle runs between a factory and warehouse. However, new solutions offering more cost and capability options and zero trailer modifications mean a much wider range of businesses stand to benefit – such as those operating in Direct-to-Consumer (D2C) applications where 3PLs will often send any available trailer to transport goods. Tomi Korhonen, Managing Director, Actiw Oy – part of the Joloda Hydraroll Group, explains.

A report by STIQ recently confirmed a rule of thumb that automation needs to deliver return on investment (ROI) in three years or less for a business case to compete with manual flows. In the world of logistics, this is not unique to automated trailer loading systems (ATLS). However, ATLS are proving a good example of how access to automation is changing. Labour shortages, rising operational costs and high throughput demand are universal challenges regardless of size or sector – so while not every business is ready to invest in full automation, or has the business case to make it immediately viable, the majority are under pressure to do more, faster. A greater variety of solutions with different price points and capabilities is helping open up the benefits of automated pallet handling to a far wider range of companies – but they may not be aware.

Expanding the definition of ROI

The benefits of an automated trailer loading system are vast: reduced loading times lead to higher throughput and operational cost savings, in addition to improved safety, accuracy and consistency. However, many logistics operators are still early on in their automation journey. Labour shortages, safety concerns, and rising operational costs may be accelerating interest in automated solutions, but hesitancy remains due to cost, space constraints, and operational rigidity – all of which influence their viability for certain use cases. While the throughput of pallets is high, constrained warehouse footprints, semi-automated or manual upstream operations (such as delivering directly to a customer that uses a forklift truck to unload pallets), or a large distance between two facilities, can make full-scale automation – and the required modifications to existing infrastructure and trailer fleets – more difficult to justify.

It is also the case that ROI in automation isn’t the same for every use case and vertical. While throughput is a key factor, there are many other value drivers that need to be considered – particularly in specialised environments. In cold chain logistics, for example, reducing damage to trailers can be just as critical as speed. In sectors where contamination must be avoided, the quality control offered by automation becomes a central advantage. Safety is another major factor: dock areas are among the most hazardous in the warehouse, and reducing human intervention here can have a significant impact.

What’s needed is a middle ground: solutions that offer a range of costs and capabilities for more businesses to introduce automation into their pallet loading and unloading processes and receive a fast return on their investment.

Filling the market gap

There’s a clear gap in the market for compact, low-commitment automated trailer loading systems that can enable businesses to increase their daily loading capacity without requiring extensive modifications to existing site and fleet infrastructure. New developments are beginning to fill that gap.

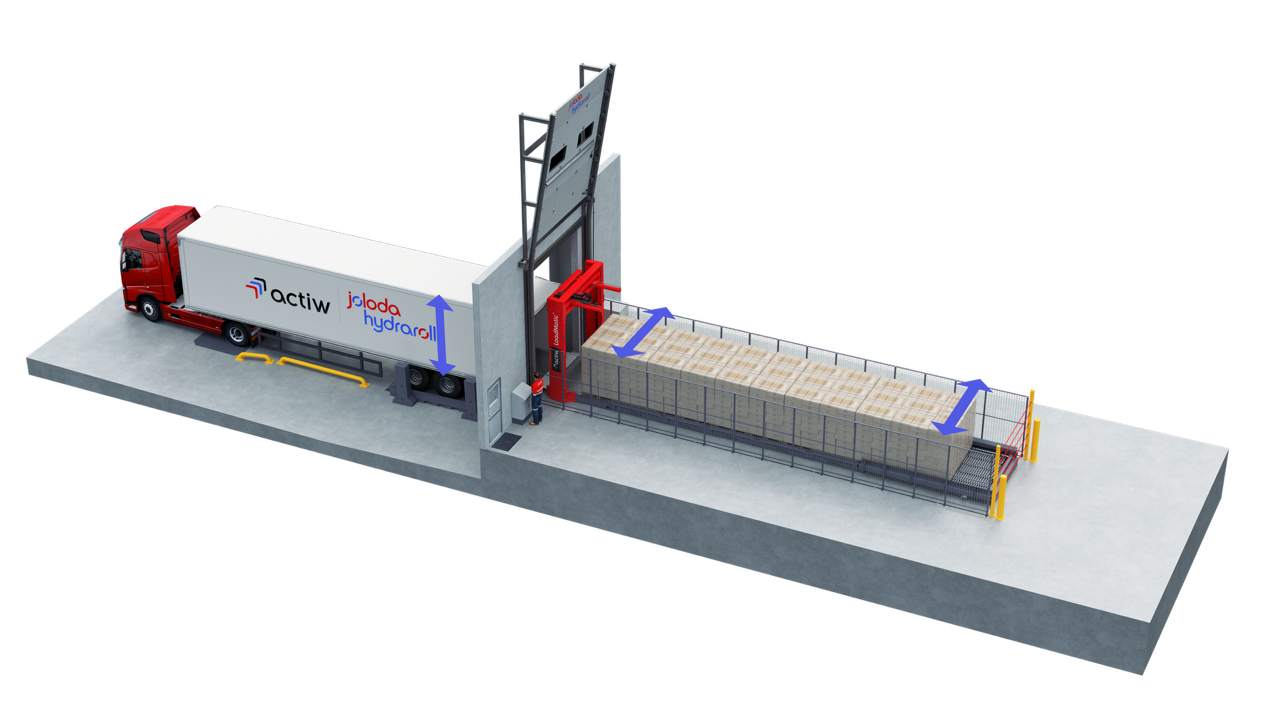

Modular, bolt-on systems now exist that allow for a wide range of pallet types and complex load patterns (manual or automated), and integrate with all standard docks. These approaches reduce upfront cost while still improving efficiency, productivity, and safety. The new LoadMatic Lite from Actiw, a subsidiary of the Joloda Hydraroll Group, is capable of loading full, standard, non-modified trucks and trailers in just six minutes. Pallets are staged at the rear or side of the dock using forklifts, electric pallet stackers, or AGVs, queued, and then loaded in one shot with precision.

The price point typically comes in at one-third of the cost of traditional ATLS. Pilot simulations have demonstrated ROI in as little as 13 months – making automated trailer loading systems an increasingly accessible strategy, and allowing more businesses to transition to automation as they grow.

For many companies, trailer loading has remained unchanged for decades. But faced with workforce challenges, rising demand, and a general requirement to achieve more with less, automation is necessary for all businesses to help improve reliability, safety, and resilience. But, of course, only if it is financially viable. For most companies, this means an ROI in less than three years. A broader range of solutions and price points are now available so that growing businesses don’t need to dive straight into fully automated systems but can begin to reap the benefits and evolve their operations over time. In doing so, they build a more sustainable foundation for future automation and competitive advantage.

similar news