Robotic solutions for automated storage and retrieval, as well as order picking, provide the secret to successfully hitting seasonal peaks – and can give a competitive edge at this crucial time of trading, writes Stefan Pieters, CEO of Movu Robotics.

Imagine having the technology that gives you the ability to meet Christmas peaks successfully. Flexible robotic automated warehousing solutions are fulfilling many Christmas wishes by helping retailers and logistics operations overcome the challenges of peak trading season, in addition to gaining a competitive edge.

Over recent years, the seasonal peak in demand for many sectors has stretched into what has become known as the ‘Golden Quarter’, which runs through a series of festivals including the seemingly ever-growing event of Halloween, the post-Thanksgiving shopping extravaganza that is Black Friday and on into Christmas.

This peak season may well be spreading even further. Research by McKinsey found that US consumers’ holiday shopping is starting earlier and lasting longer this year, with most starting in October or earlier and 40% intending to start in November, compared with 35 percent in 2022.

Forrester is forecasting that total end of year holiday retail sales in the US will reach $969 billion, reflecting a 4.3% year on year (YoY) increase. Retailers are at the sharp end of the Golden Quarter when they generally make most of their sales. For many, it generates more revenue than the first three quarters of the year combined. The volume of goods to process to meet this demand can suddenly increase on average, depending on sector, by around 40%.

Christmas itself is the summit of the peak period. According to Statista, among the three leading European countries, the total value of Christmas spending in 2023 – both online and instore – is forecast to be the highest in the United Kingdom (UK) with almost £85 billion followed by Germany at nearly £74 bn and France at £62.83 bn.

This boom in trading has the potential to overload supporting logistics operations lacking in preparedness, creating a balancing act between driving sales and maintaining profitability. A recent survey led by Deposco of 200 supply chain leaders working for European retailers, manufacturers, wholesalers or 3PL/4PL firms found that 41% of European supply chain executives expect this year’s peak retail season to be more challenging than that of 2022, with only 18% believing it will be less difficult.

Adding to this is the requirement to handle an ever more complex assortment of goods to fulfil ever growing numbers of ever smaller orders. Customer expectations on lead times are shrinking from days to just hours, placing pressure on businesses to stock, pick, pack and ship from smaller, local facilities, and efficiency in handling returns is gaining far greater prominence as retailers battle to protect margins.

With profit margins under intense pressure and given the crucial role warehouse operations play in ensuring that customers are not let down, retailers are looking for flexible and cost effective intralogistics solutions that can help to improve their bottom line and achieve their priorities – including continuity of customer service levels. Competition is so intense that there are no second chances for a late or erroneous shipment and brand value can be swiftly eroded through poor delivery experiences.

So, it’s all hands to the pumps – except there aren’t enough available hands. Staff are generally not plentiful on potentially expensive agency books. Many among a company’s existing staff will have booked holidays, there may be an increase in sick days over the festive period, or staff may simply not be keen to work unscheduled overtime.

How to cope

Forward planning and flexible intralogistics are essential to meet demand and cope with an unexpected influx. To support the need for flexible intralogistics processes it makes sense to have in place easily adaptable, robust and reliable equipment that not only performs everyday functions, but can also be scaled up whenever necessary to meet peak demand.

A growing number of companies are adopting robotic solutions in their logistics processes. They provide far greater flexibility than conventional automated handling systems, and can seriously boost productivity, throughput and operational accuracy, even in ‘steady state’ operations. Pallet and bin shuttle systems for automated storage and retrieval are a prime example. With modular design, acting as a set of building blocks to minimise complexity and cost of upgrading, these systems are highly scalable –installations can start small and then expand or, if needed, they can downsize just as easily.

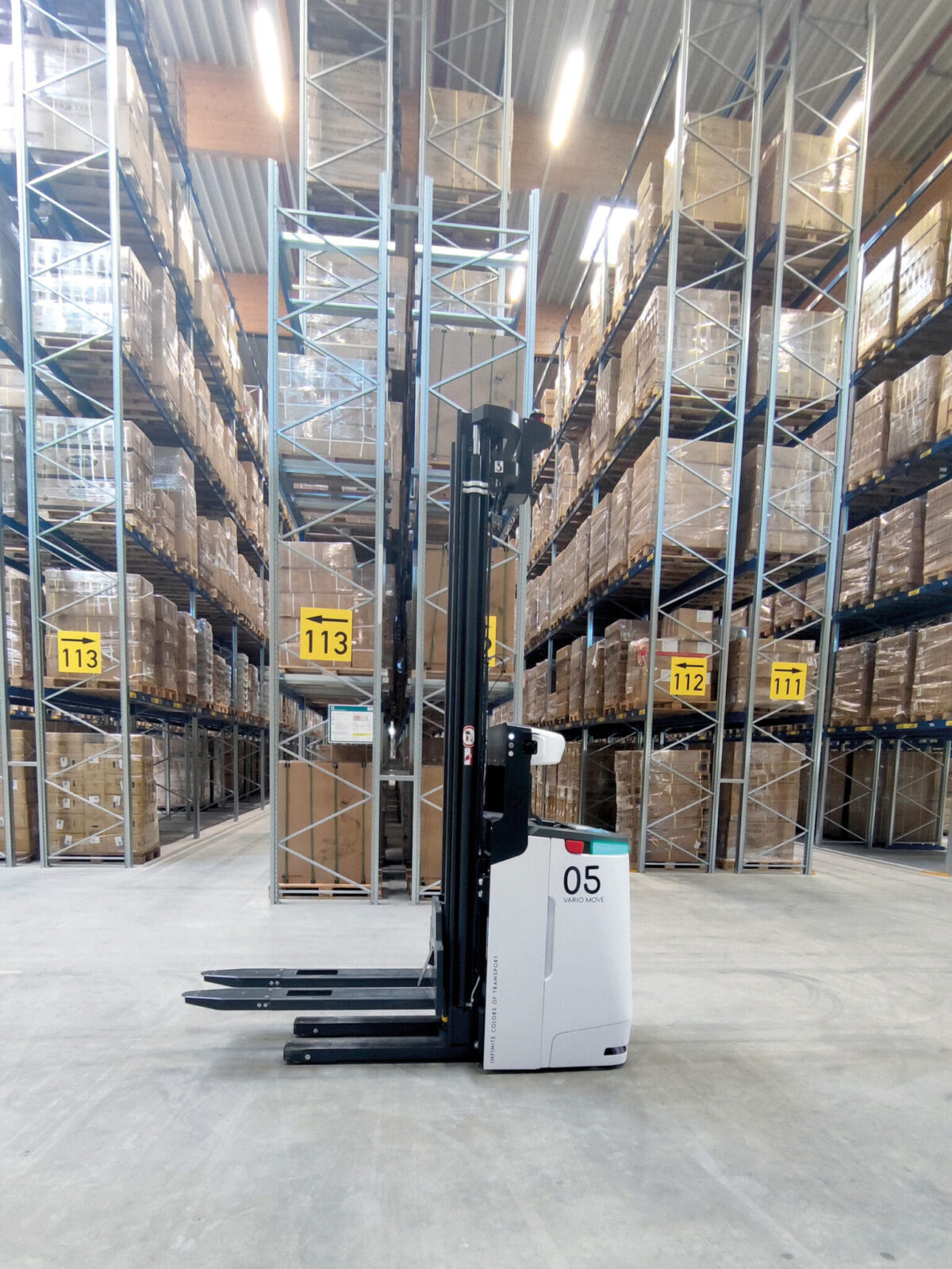

Shuttle systems provide a high density, multi-pallet position automated storage and retrieval system that maximises storage capacity while also removing manual handling, helping to reduce both personnel risk and picking errors. Self-powered robot carriers transport pallets on the rails within the storage lanes of the racking where the pallets are housed, and on the rails of the main lane that runs across the storage lanes it serves. Software manages the shuttle traffic within the system, issuing orders from a Warehouse Management System (WMS).

Using picking robots at the workstations of bin shuttle storage systems add to this flexibility. So will using Autonomous Mobile Robot (AMR) systems for pallets and additional load carriers to provide flexible transport to and from the shuttle systems, as well as used as ‘cobots’ to support order picking operations.

The benefit in terms of handling peaks is the ability to add individual robots – either shuttles, AMRs or picking arms, as demand requires. Much easier than complex reconfiguration of conventional, stacker crane-based automated systems. In addition, with shuttle systems, robots can be moved between the levels of a system to optimise throughput.

With these kind of robotics systems, the joy for companies coping with seasonal peaks is that you don’t have to use, and incur the expense of, the whole capacity. At low volume times, just use a few robots – at the peak, introduce the whole fleet.

Bringing automation to all warehouses

Robotics in the form of shuttle systems and AMRs, such as those offered by Movu Robotics, bring easier automation solutions to all warehouses. In particular, they provide opportunities for SMEs, with as few as 5000 pallet locations, to steal a march on larger retail organisations that may have committed to less than flexible, fixed automated systems. With the combination of intelligent software and advanced robot technology, SMEs can leverage the flexibility, speed and performance of this kind of goods-to-person automation as a low-CapEx project. This ensures that when it comes to opportunities for automation, no warehouse is left behind.

Simple, standardised plug and play solutions for warehouse automation and robotics are more accessible and more scalable. They also create an impressive business case for companies. Even operating ‘off-peak’ at well below capacity there is a rapid Return On Investment with labour redeployed to other tasks, such as picking. But it is at peak times when these systems really come into their own, ramping up throughput without any corresponding increase in labour, and minimising the burden on dispatch and delivery operations. Movu recently installed an atlas 2D robotic shuttle system for a company serving the Chocolate industry, for which Christmas is a significant peak alongside Easter. The flexibility that the shuttle system provides not only helps it to manage these peaks but also facilitates future growth.

By choosing Intelligently designed and flexibly integrated robotic automated warehouse solutions, retailers, manufacturers and logistics operations can meet their fulfilment promises, even during peaks, while saving money. And, importantly, automation isn’t ‘just for Christmas’. It can be scaled and flexed to give benefits throughout the year, in both peak and slack seasons, bringing a multitude of savings. This kind of wise deployment of automation enables a business to not just simply survive, but to thrive.