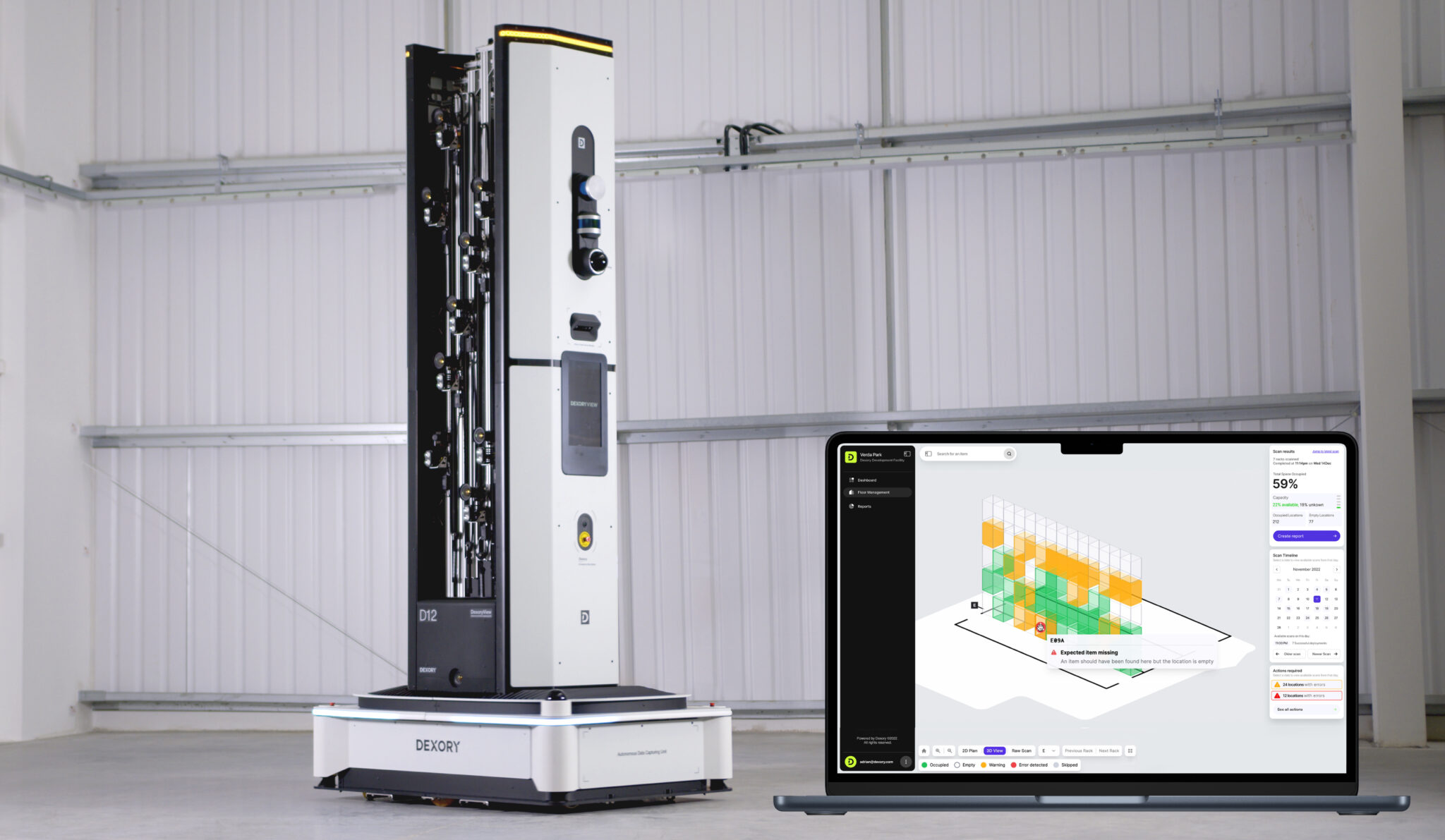

Automated internal logistic platforms, such as AGV and AMR, as well as other industrial autonomous robots, are becoming more widespread due to lithium-ion batteries, as their apparent advantages make them more attractive than the various alternatives.

Previously, most used batteries with lead-acid based chemistry, like forklifts and other industrial mobile machines. Regardless of the specific type, these lead-acid based batteries are considered to have poor lifespans, especially when used in deep discharge cycles. The rapidly growing global market for lithium-ion batteries has allowed Johnson Matthey Battery Systems to become a leader in the industry, opening up several growth opportunities. As it now stands, the company has developed a full-service manufacturing capability, allowing it to offer a cost-effective solution for all customers.

Due to the low lifespans of lead-acid based batteries, many are now instead opting for lithium-ion batteries, which have a lifespan that’s approximately 4x longer. This is partly down to energy density, which can be up to 5x higher in li-ion batteries (50-100Wh/kg in lead-acid vs up to 260 Wh/kg in NCA/NMC cells). What’s more, lead-acid based batteries can be cumbersome, unlike Li-ion batteries, meaning they’re unsuitable for many mobile robots.

Mitigating Against Safety Concerns of Li-ion Batteries

As with many new technologies, li-ion batteries have some downsides, with the biggest being the concerns over their safety. Thermal runaway is possible in the event of overheating or overcharging, which can lead to fire. But the risk from this can be minimised. Johnson Matthey Battery Systems has achieved this by utilising a Battery Management System – which can also be used to gauge information about a battery – and by ensuring a robust mechanical design.

Moreover, most high-quality batteries have secondary backup protection, such as a fuse or SCP. A robust design is also critical, protecting the battery from physical damage while also contributing towards a long lifespan. Cell holders, cell connectors, enclosures – all should be constructed to the highest possible specifications for maximum effectiveness.

Cell Chemistry to Further Enhance Safety

LFP cell chemistry is now being used in many industrial applications to enhance safety further. This is still li-ion technology but behaves less violently when subjected to any type of force. Even ruptured LFP cells only cause smoke or minor fire contained within the battery, plus their thermal runaway temperatures are higher than NMC and NCA. LFP cells also have an exceptionally high cycle life, even with 100% Depth of Discharge (DoD). Depending on the model, the figure could reach 2,000 or more cycles, around double that of NMC and up to quadruple that of NCA. Add in DoD reduction, and the total number can be several thousand more.

There is a trade-off for the extra safety and performance: the energy density is lower than NMC and NCA – currently, it is 150-200 Wh/kg vs 220-270 Wh/kg. But the energy density is steadily improving and is already acceptable for industrial applications. What’s more, it is already up to 4x higher than that of lead-acid. Thanks to this improving energy density, LFP cells are now becoming the preferred choice for many industrial batteries.

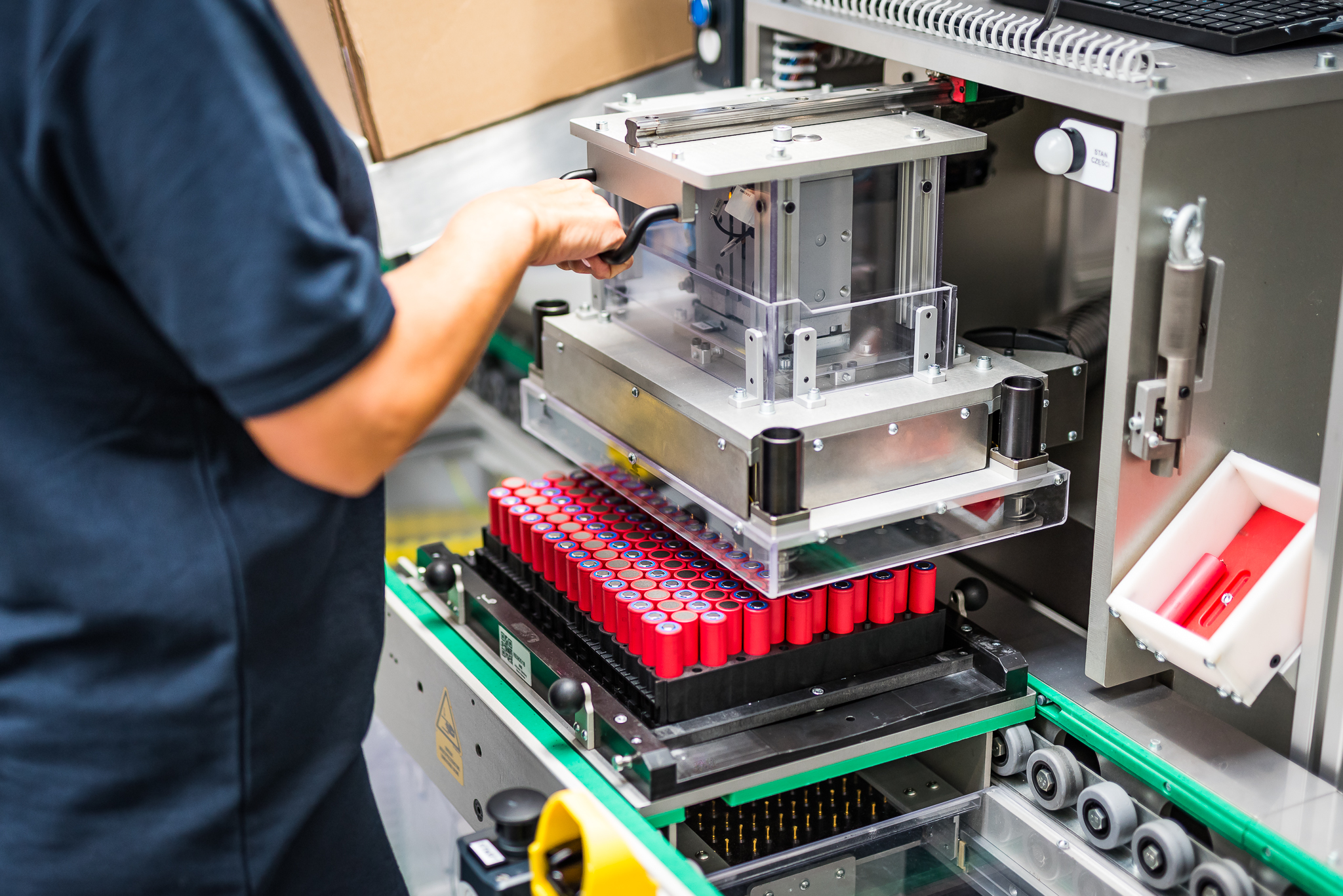

The manufacture of LFP batteries has some challenges, but these shouldn’t stop experienced manufacturers, such as Johnson Matthey Battery Systems, from manufacturing them effectively.

Johnson Matthey Battery Systems, part of the Johnson Matthey group, is a European-based manufacturer of advanced battery systems with considerable experience within the field. The company specialises in lithium-ion battery assembly processes, manufacturing a wide range of battery packs with various applications, and operates in all other areas of battery production, including design, prototyping, and assembly. It designs and manufactures advanced battery systems of 3.6V to 60V, utilising its expertise and manufacturing capabilities to produce batteries that meet all international standards and the expectations of customers from various industries.

Currently, Johnson Matthey Battery Systems is working on several new projects, as well as internal projects to develop its manufacturing capabilities. With the market for AGVs currently increasing, the company expects to further develop its footprint in this area. One area of particular interest is improving battery pack performance by increasing lifecycles. This focus on improvement has helped JMBS to become one of the world’s most trusted li-ion battery manufacturers.