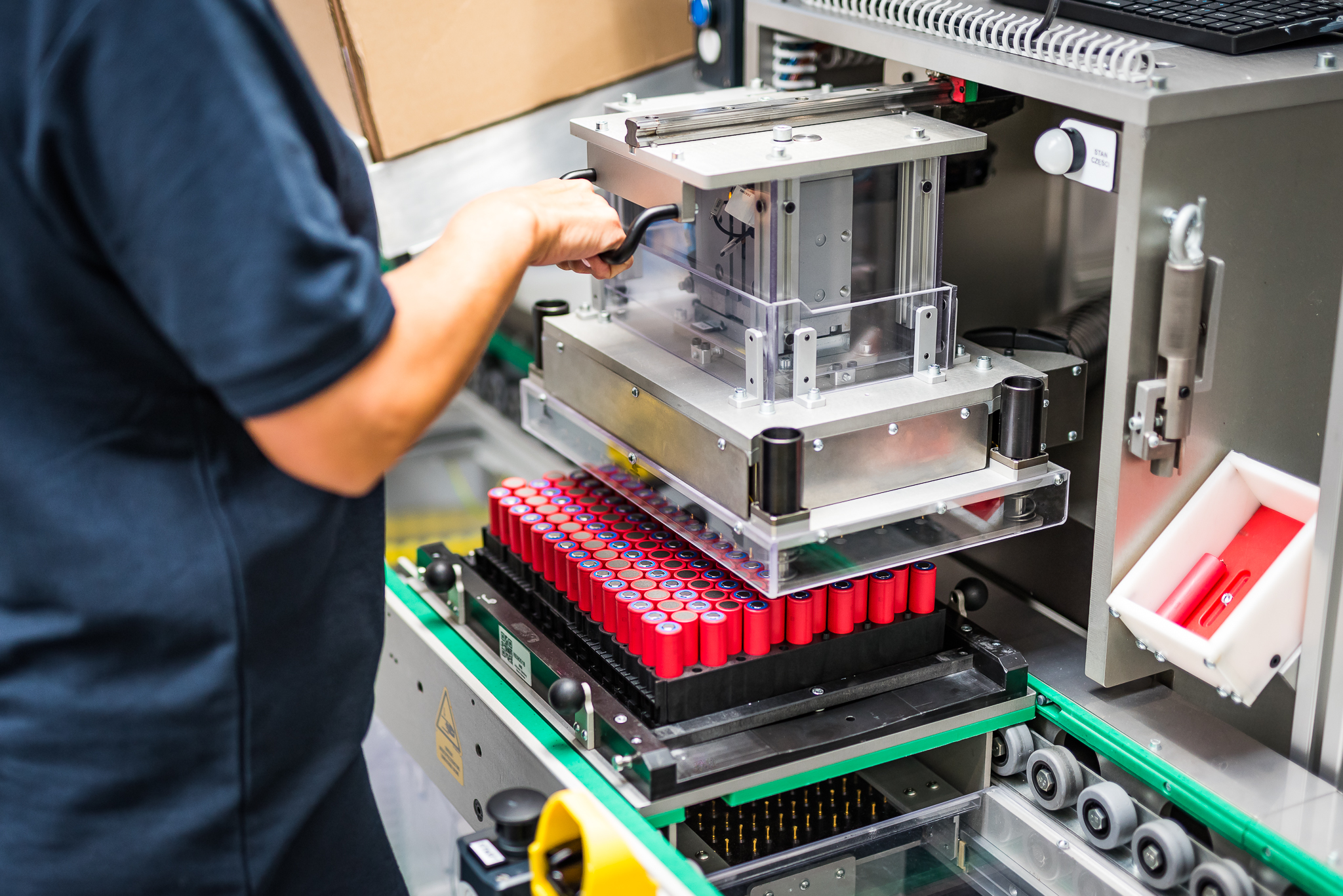

DHL Supply Chain has signed a long-term contract with Fortum Battery Recycling, a business of the Nordic energy company Fortum. The agreement covers the development and provision of customized service logistics solutions for the recycling of electric vehicle (EV) batteries. With this partnership, both companies are making an important contribution to promoting sustainable supply chains and conserving valuable resources.

Fortum Battery Recycling is the only player providing a European solution for every stage of the battery recycling value chain. The company is a pioneer in the development of processes to efficiently recover valuable raw materials such as lithium, cobalt, and nickel from used batteries with minimal waste residue, thus driving forward the circular economy in electromobility. Under the agreement, DHL Supply Chain will provide customized service logistics solutions to ensure that Fortum’s recycling processes run smoothly, safely, and efficiently.

Forward-looking service logistics solutions for battery recycling

DHL Supply Chain’s service logistics goes beyond conventional logistics services. The aim is to ensure the business success of customers by guaranteeing the functionality of products and technologies throughout their life cycle. In the field of battery recycling, this means that DHL Supply Chain is responsible for the entire spectrum of services in the logistics segment. These include the safe transportation, storage, and handling of used EV batteries, as well as timely delivery to Fortum’s recycling facilities.

“Our collaboration with Fortum underscores our commitment to providing innovative logistics solutions to meet the growing demands of e-mobility,” explains Hendrik Venter, CEO at DHL Supply Chain EMEA. “Through our expertise in service logistics and our global network, we can help Fortum expand their recycling capabilities while maintaining the highest safety and sustainability standards.”

Sustainable solutions for electromobility

For Fortum, the cooperation with DHL Supply Chain is an important step in further expanding its sustainable recycling solutions and making the market for electric vehicles even more environmentally friendly. “We are proud to be working with DHL Supply Chain to develop an efficient and sustainable logistics solution for the recycling of EV batteries,” comments Anssi Airas, Head of Business Line Battery at Fortum. “We believe that electrification of Europe is not possible without sustainable recycling of batteries taking place in Europe, for Europe. The cooperation with DHL is an essential building block for our mission to promote the circular economy and maximize resource conservation.”